Bearing cover angle positioning machining process equipment

A technology of angle positioning and processing technology, which is applied in the direction of positioning devices, metal processing equipment, metal processing machinery parts, etc., and can solve the problem that the tile knife positioning device has no angle auxiliary positioning mechanism, the tile cover cannot be clamped in place, manual adjustment and positioning, etc. problems, to achieve the effect of improving flexibility and convenience, and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

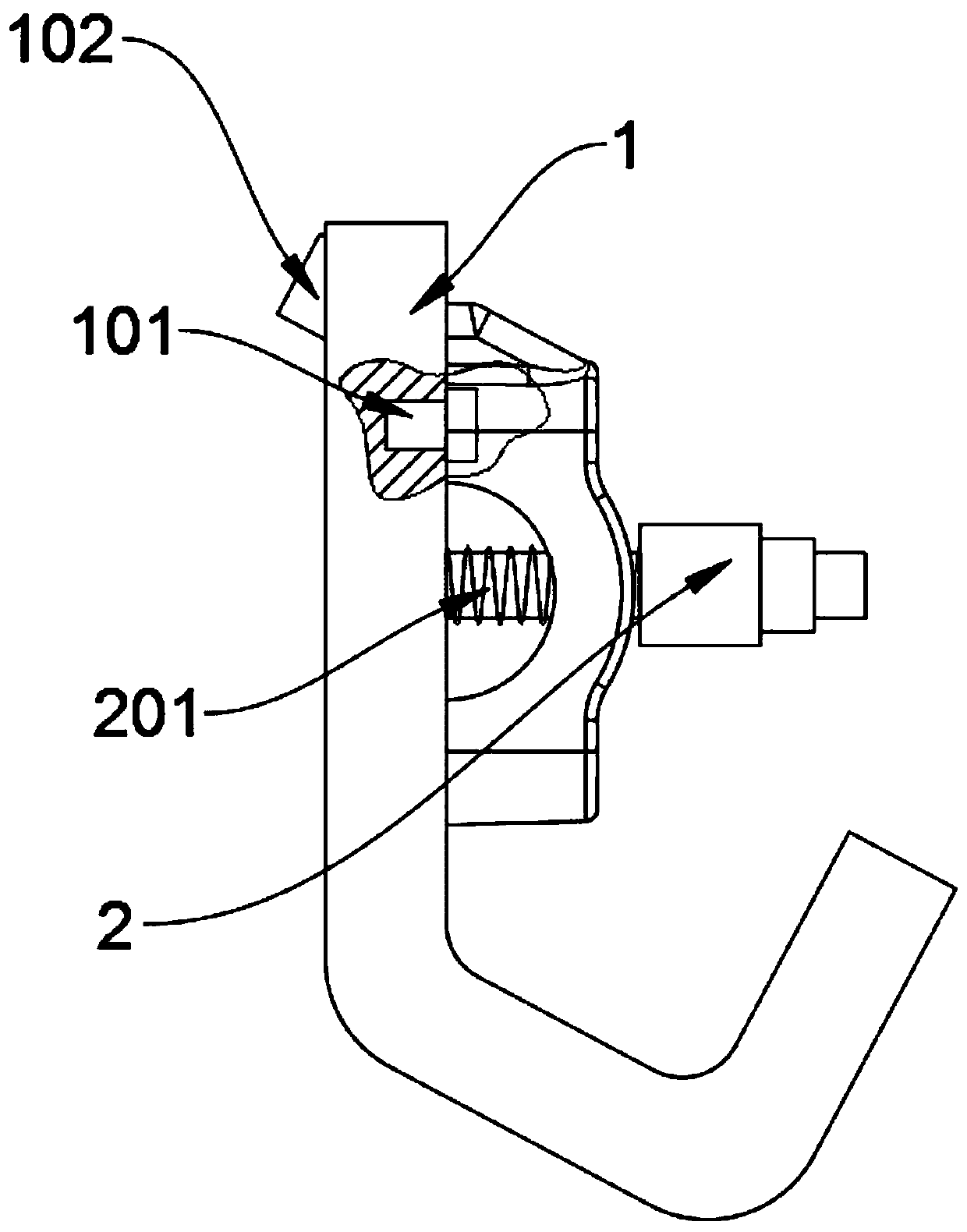

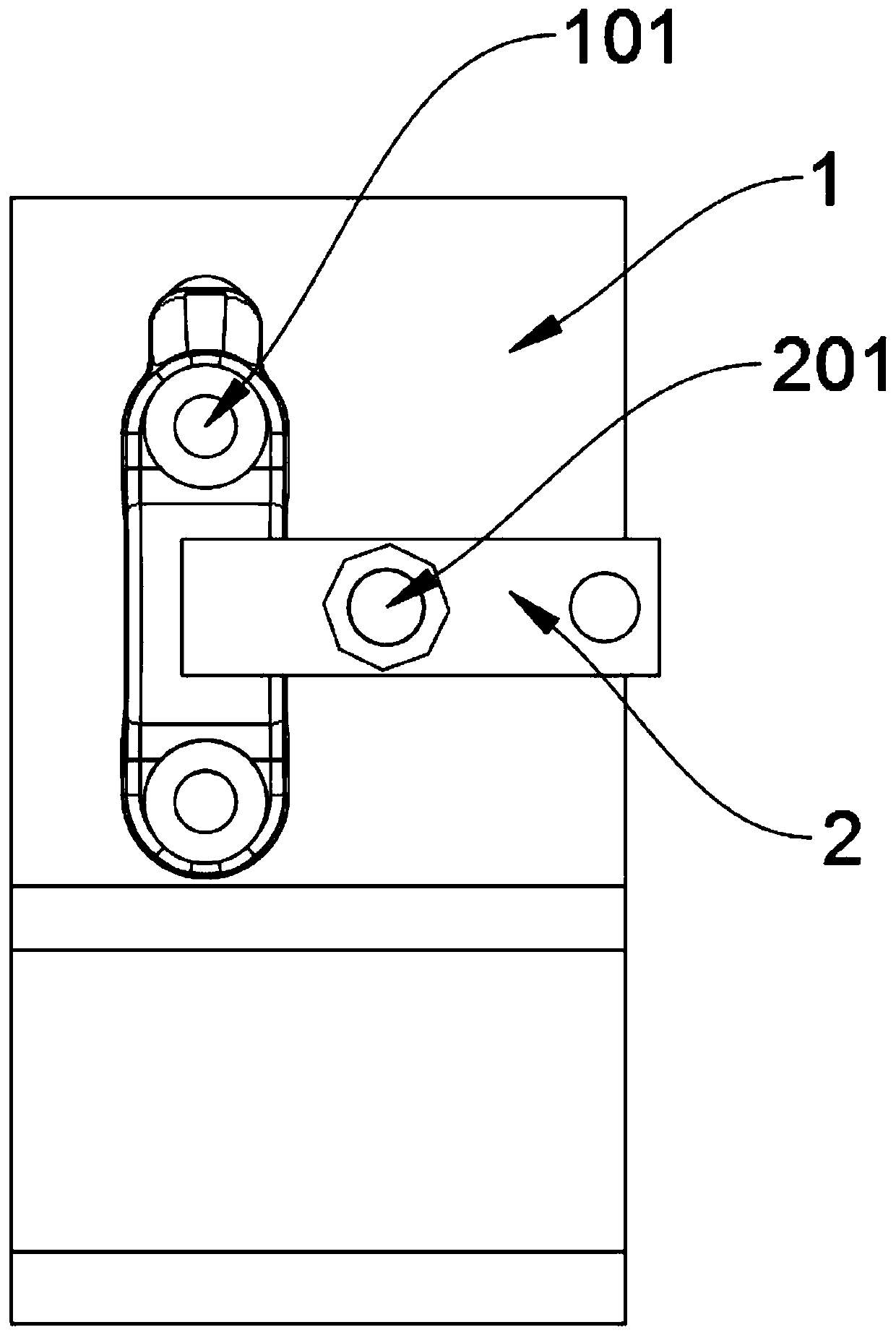

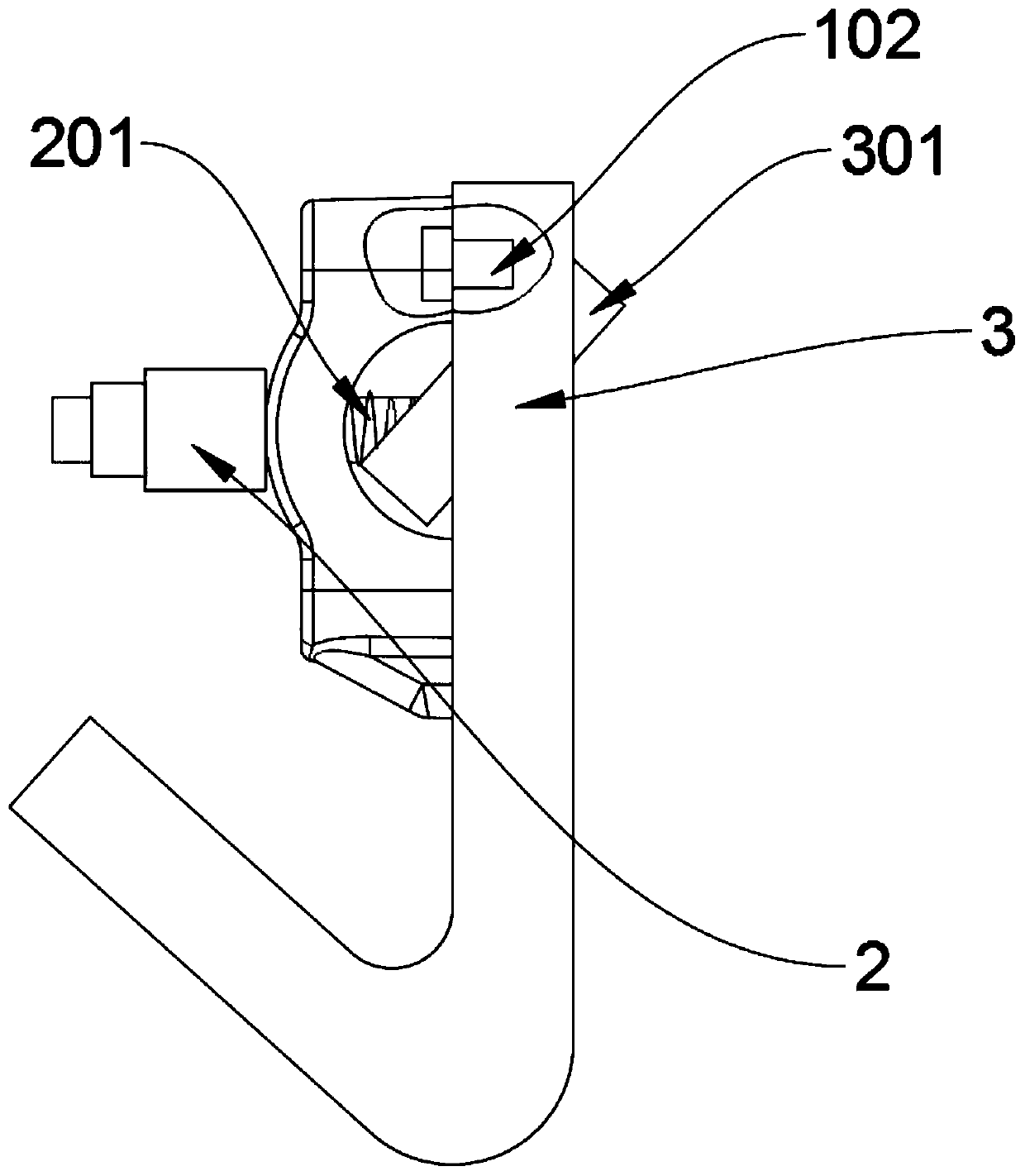

[0029] as attached figure 1 to attach Figure 4 Shown:

[0030] The present invention provides a tile cover angle positioning processing equipment, including a clamp body a1, a pressure plate 2, and a clamp body b3; the top surfaces of the clamp body a1 and clamp body b3 are provided with threaded rods 201; the bottom of the clamp body a1 is designed with double knuckles , the bottom of clamp body b3 is designed with a single corner, as attached figure 1 And attached image 3 As shown, this design enables the staff to select the fixture that needs to be used at a glance during construction, which is convenient and quick, and improves the practicability of the device; the top surfaces of the clamp body a1 and the clamp body b3 are provided with positioning pins 101, And the positioning pin bar 101 is provided with two on the top surface of the clamp body a1 and the clamp body b3, as attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com