Fixtures for pitch machining of aerospace thin-walled blades

A blade pitch and blade technology, which is applied in the production tooling field of aviation thin-walled blades, can solve the problems of unstable machining accuracy, long processing time, and high cost, and achieve improved machining accuracy and stability, improved production efficiency, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

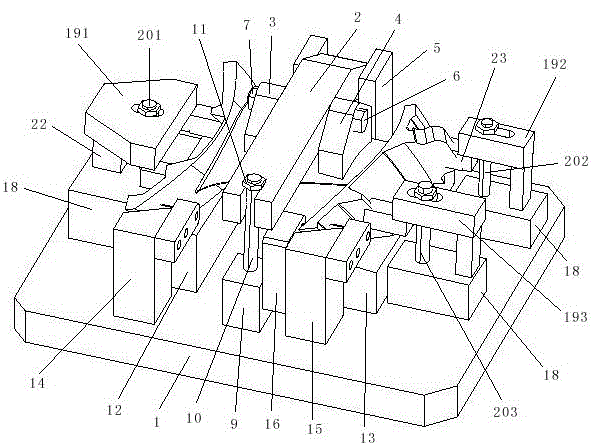

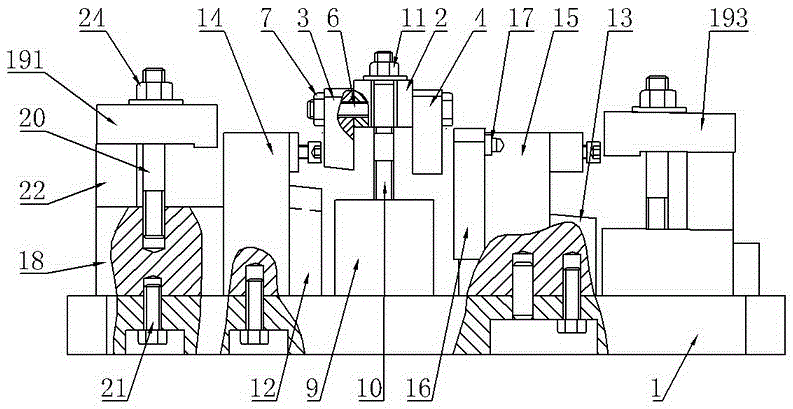

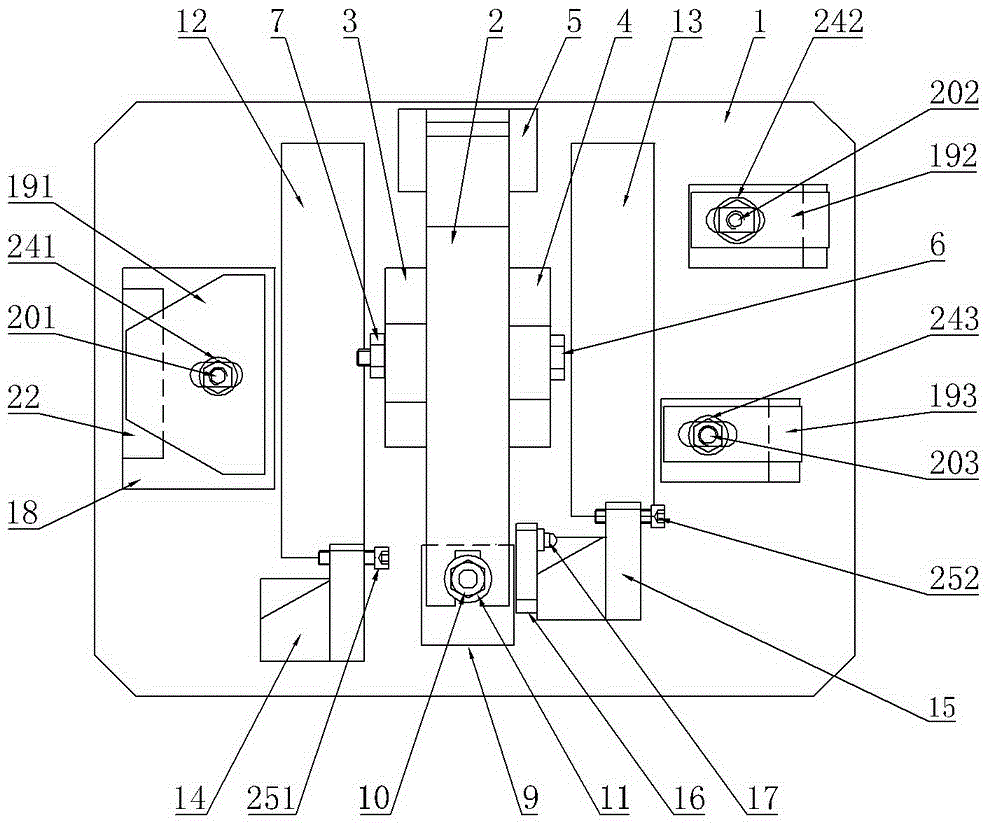

[0023] See Figure 1 to Figure 5 The jig of the present invention includes a jig bottom plate 1, the center of the jig bottom plate 1 is longitudinally equipped with an airfoil pressing mechanism, and the blade inner annulus positioning mechanism and the blade outer annulus positioning mechanism are respectively installed on the lateral outer sides of the airfoil pressing mechanism. The lateral outer sides of the blade inner ring surface positioning mechanism and the blade outer ring surface positioning mechanism are respectively equipped with a blade process boss pressing mechanism, which positions the processed inner ring of the blade through the blade inner ring surface positioning mechanism and the blade outer ring surface positioning mechanism. The radial surface and the radial surface of the outer ring are compressed by the blade body pressing mechanism and the blade process boss pressing mechanism.

[0024] The airfoil pressing mechanism includes a hinge pressing plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com