VCM coil clamp device

A fixture device and coil technology, applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of high processing and assembly difficulty, inconvenient coil assembly process, difficult positioning, etc., to ensure the uniformity of winding, shorten the The effect of clamping positioning time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

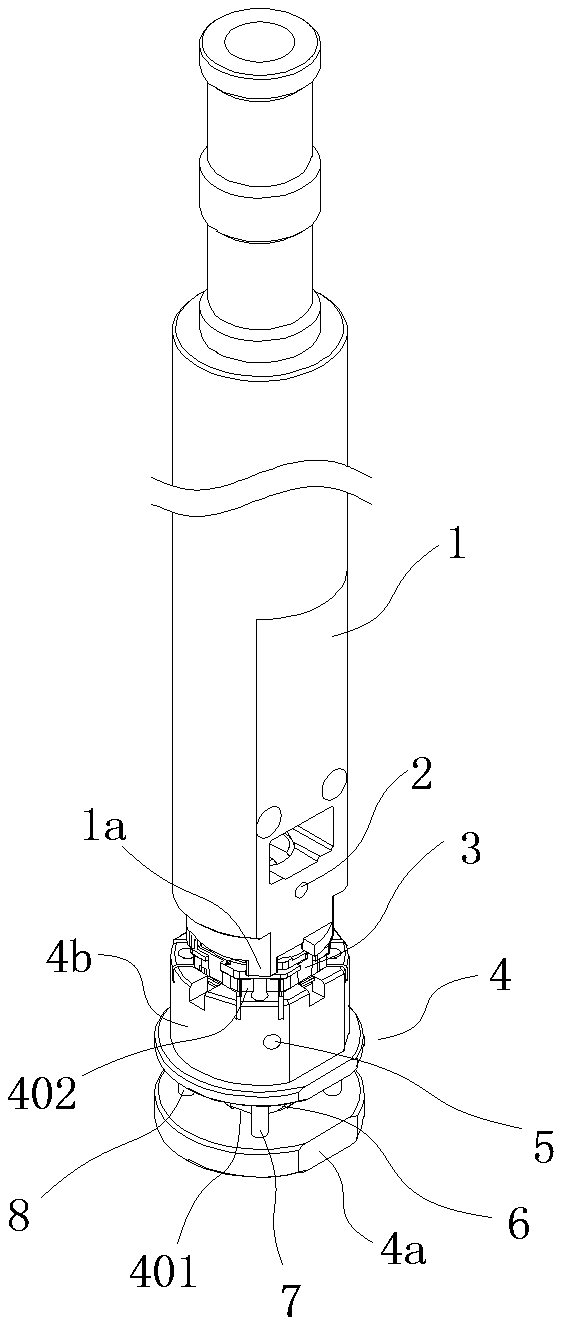

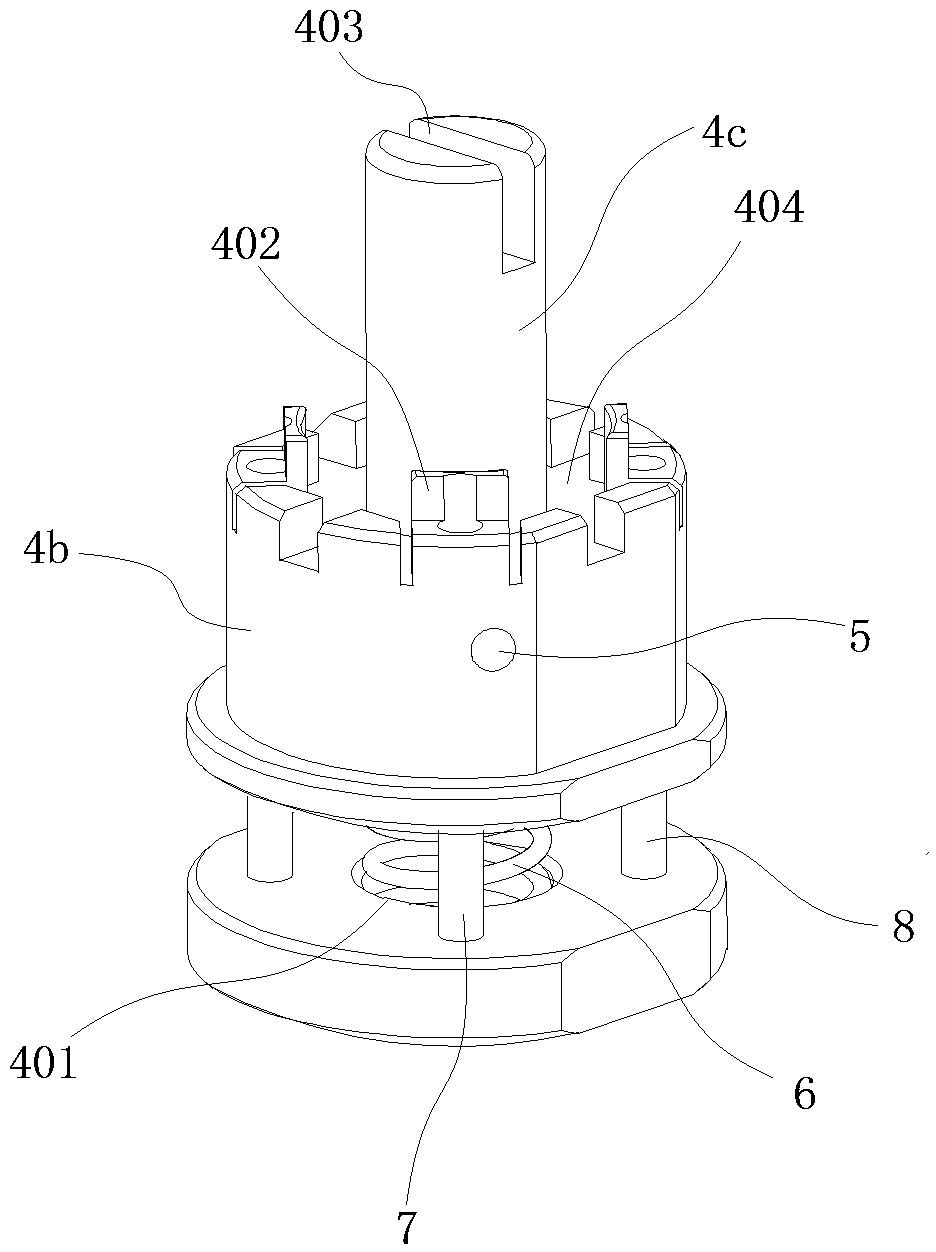

[0025] Such as figure 1 , figure 2 In the shown embodiment, a VCM coil fixture device includes a positioning shaft 1 and a positioning seat 4, wherein the positioning seat includes a seat body 4b and a positioning plate 4a, and the top of the seat body is provided with a positioning device for positioning the VCM coil 3 in the circumferential direction. The slot 404, since the VCM coil is octagonal, the positioning slot in this embodiment is also octagonal, corresponding to each side of the VCM coil. The edge of the positioning groove is provided with a positioning protrusion 402, the inner side of the positioning protrusion is flush with the inner side wall of the positioning groove, and the thickness of the positioning protrusion is smaller than the depth of the positioning groove on the VCM coil.

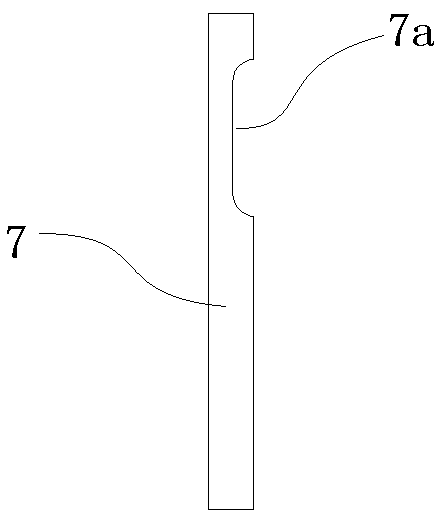

[0026] combine image 3 As shown, the center of the positioning groove is provided with a guide post 4c, the center of the seat body is provided with a through hole for accomm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com