Transmission of automatic screen printing machine

A technology of screen printing machine and transmission device, which is applied in the direction of screen printing machine, printing machine, rotary printing machine, etc. It can solve the problems such as difficult to achieve accurate positioning of the platen, large mass of moving parts, large inertia, and large motor capacity. Achieve flexible and convenient replacement, improve printing efficiency and save time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

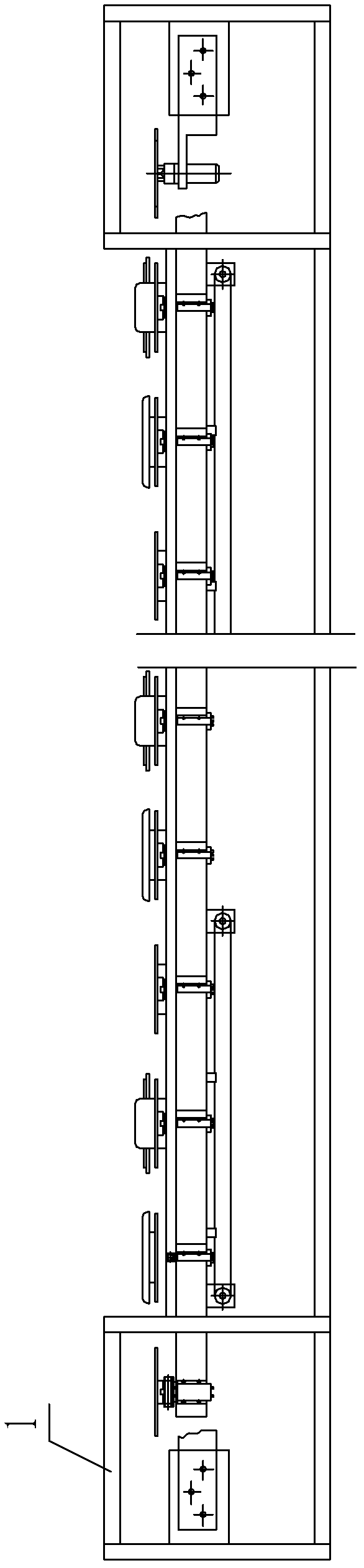

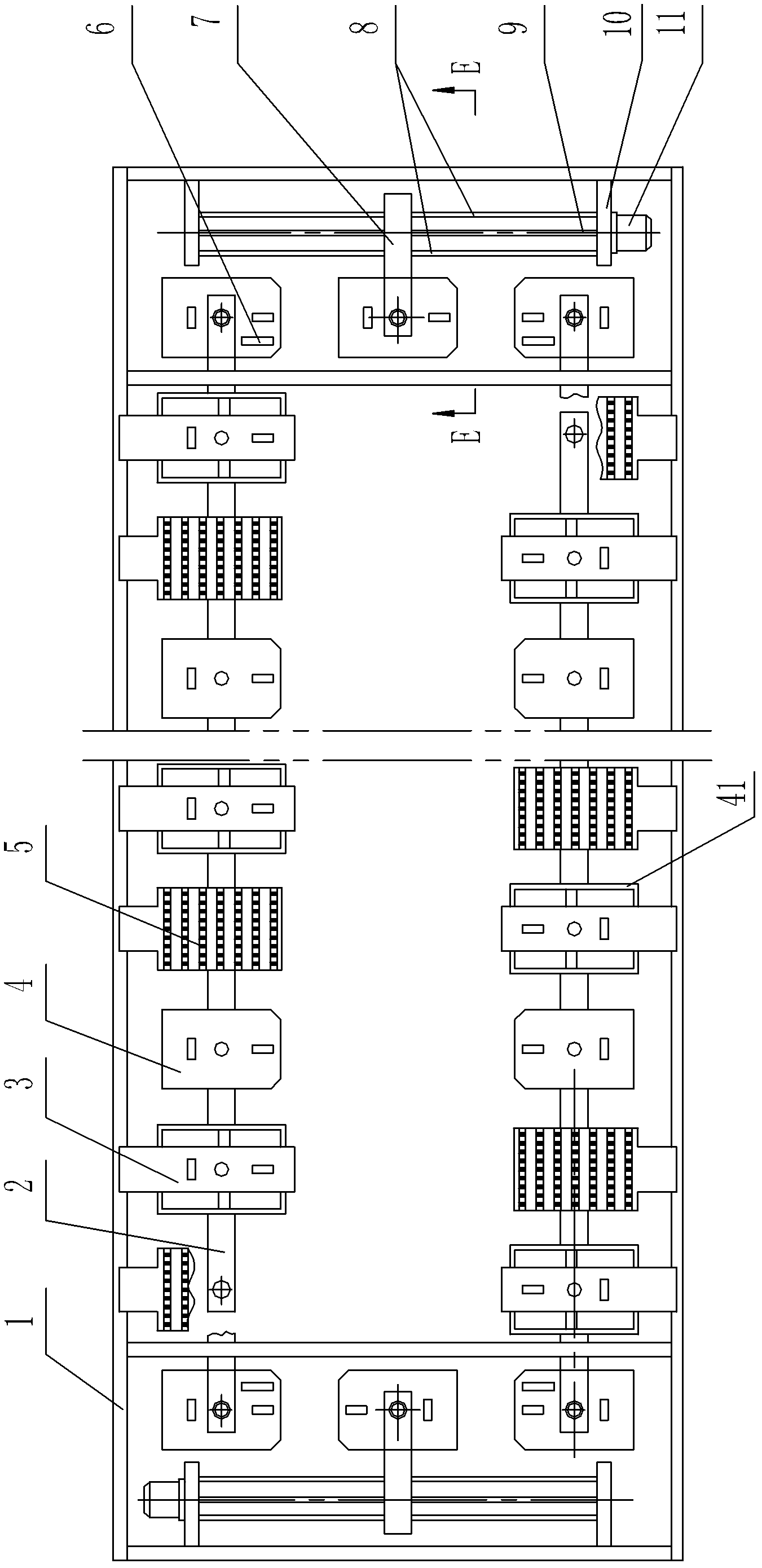

[0027] like figure 1 , figure 2 As shown, the transmission device of the automatic screen printing machine includes: the printing machine frame 1, the platen assembly, the platen moving device, the platen positioning and supporting device, and the platen steering device; the left side of the printing machine frame 1 Both the inner side and the right inner side are equipped with a platen moving device, and the platen moving device is installed on the printing machine frame 1; in the area of the front inner side and the rear inner side of the printing machine frame 1 ( figure 2 The bottom of the middle is the front, figure 2 after the top of figure 2 The left side is left, and the right side is right), and the bottom of the platen assembly is provided with a platen positioning and holding device (the platen positioning holding device and the electromagnet assembly 12 are arranged in a misplaced position, and do not affect each other), and the platen positioning and holdi...

Embodiment 2

[0046] It is basically the same as Embodiment 1, except that part of the structure of the platen moving device is different. Such as Figure 4 as shown,

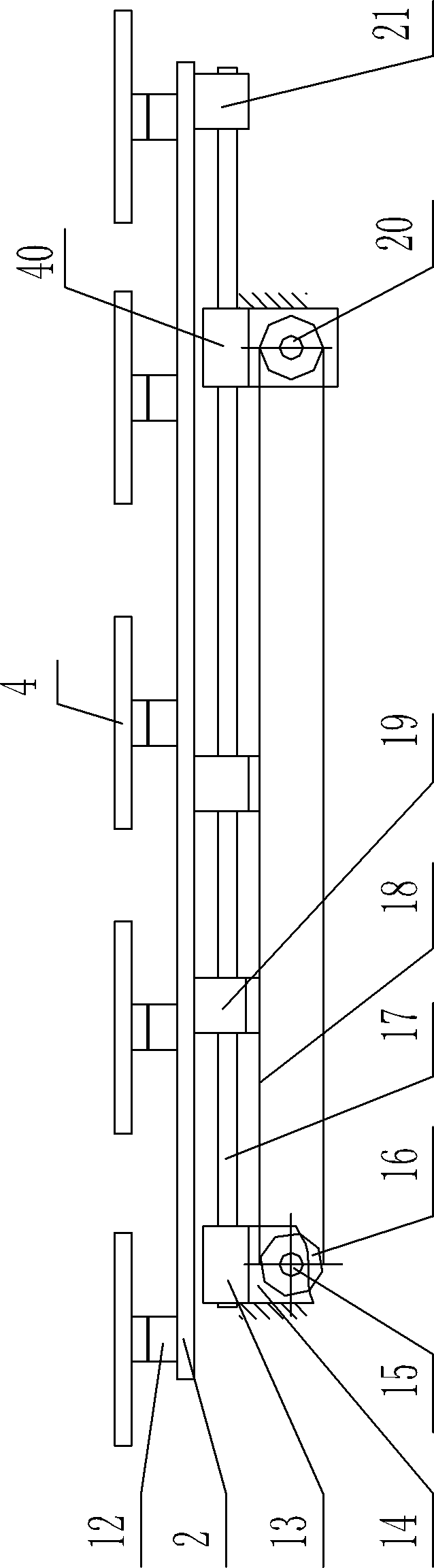

[0047] The second structural form of the table moving device is composed of more than one table moving unit (such as 2, or 4, 6 or 8, etc., the specific number is determined according to the size of the screen printing machine), each table The moving unit includes an electromagnet assembly 12, a moving seat plate 2, a first guide rail support block 13, a first transmission wheel seat 14, a first rotating shaft 15, a second rotating shaft 20, a first driving wheel 16, a table moving guide rail 17, Transmission body 18, moving seat plate connecting block 19, table moving motor; the output shaft of the table moving motor is connected with the first rotating shaft 15 or the second rotating shaft 20 by a coupling (providing the power for moving the moving device), and the table moving The motor is fixed on the corresponding fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com