Full-servo back label printing, intaglio printing, rotary screen printing and embossing register control method

A control method and back labeling technology, applied in printing, printing machines, general parts of printing machinery, etc., can solve problems such as large overprint error and unstable printing quality, and achieve the goal of increasing yield, reducing labor intensity, and increasing economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

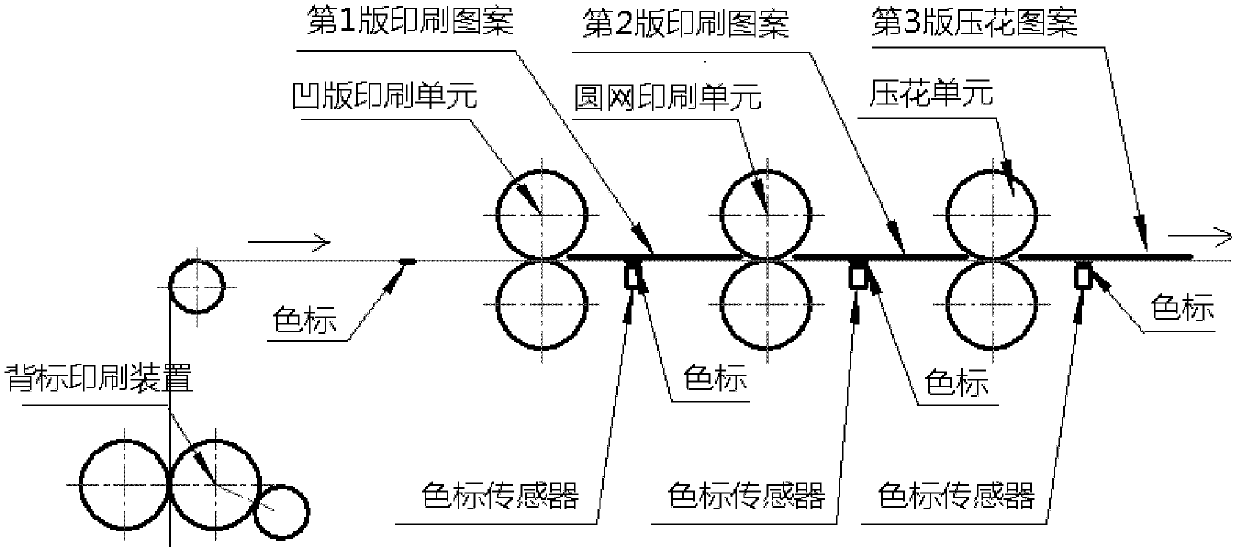

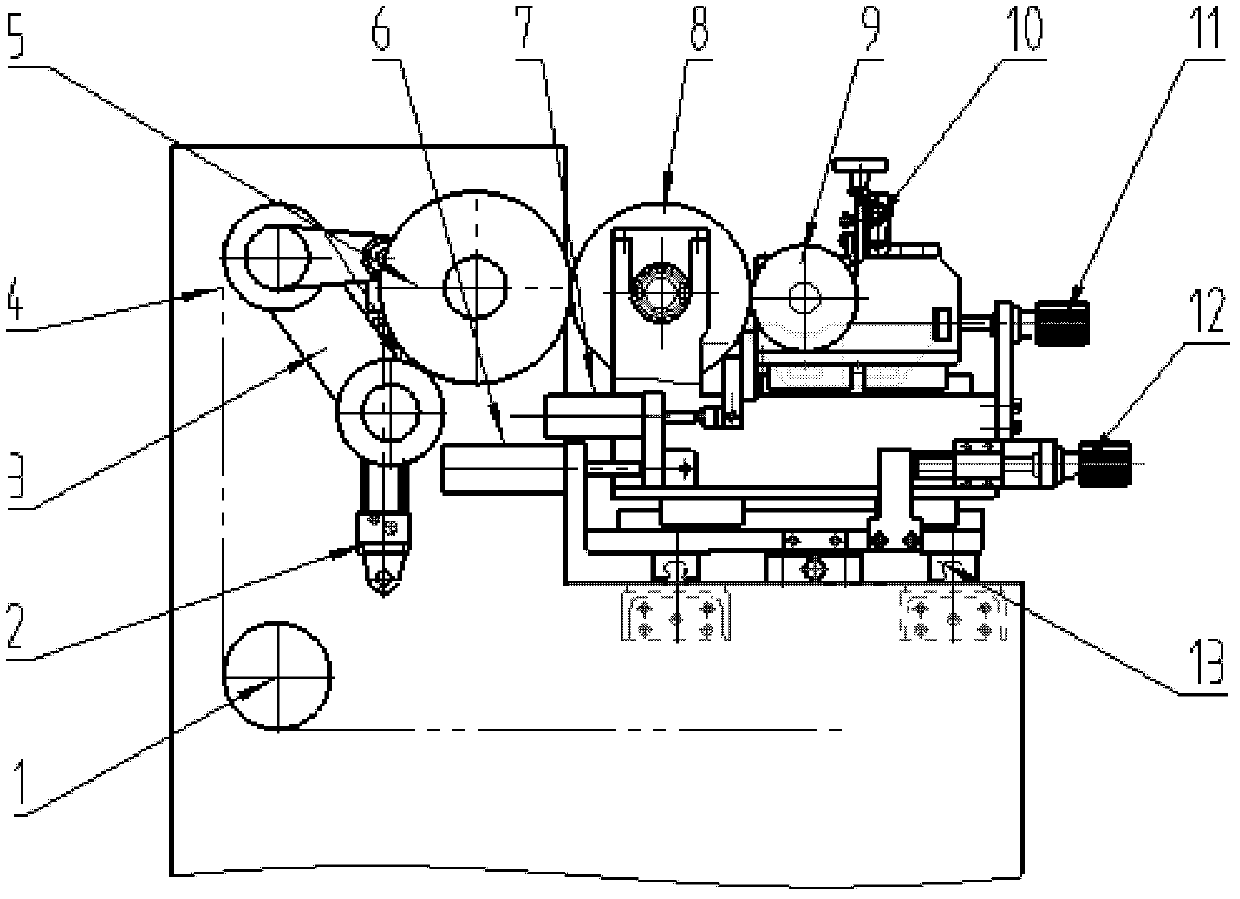

[0014] refer to figure 1 , Flexographic back label printing A dark color mark is printed on the back of the paper tape. The first printing pattern is completed by the gravure printing unit, using a gravure printing device. The second printing pattern is completed by the rotary screen printing unit, using a circular Screen printing device, the embossing pattern of the third edition is completed by the embossing unit, using an embossing printing device; a color mark sensor (that is, a single photoelectric eye) is set at the discharge end of each unit, and each color mark sensor is connected with the color registration controller The signal connection is realized, and the color registration controller is connected with the servo motor encoder of each unit plate roller respectively.

[0015] The model used for the color mark sensor (photoelectri...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap