Device for automatically separating bobbin from groove drum after yarns of groove drum doffer are broken

A technology for automatic separation and winding spool, which is applied in the field of automatic separation grooved tube device for thread breakage bobbin doffer of grooved doffer, which can solve the problems of yarn breakage, easy fatigue of grooved doffer, increased labor cost, etc. The effect of avoiding damage to the yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

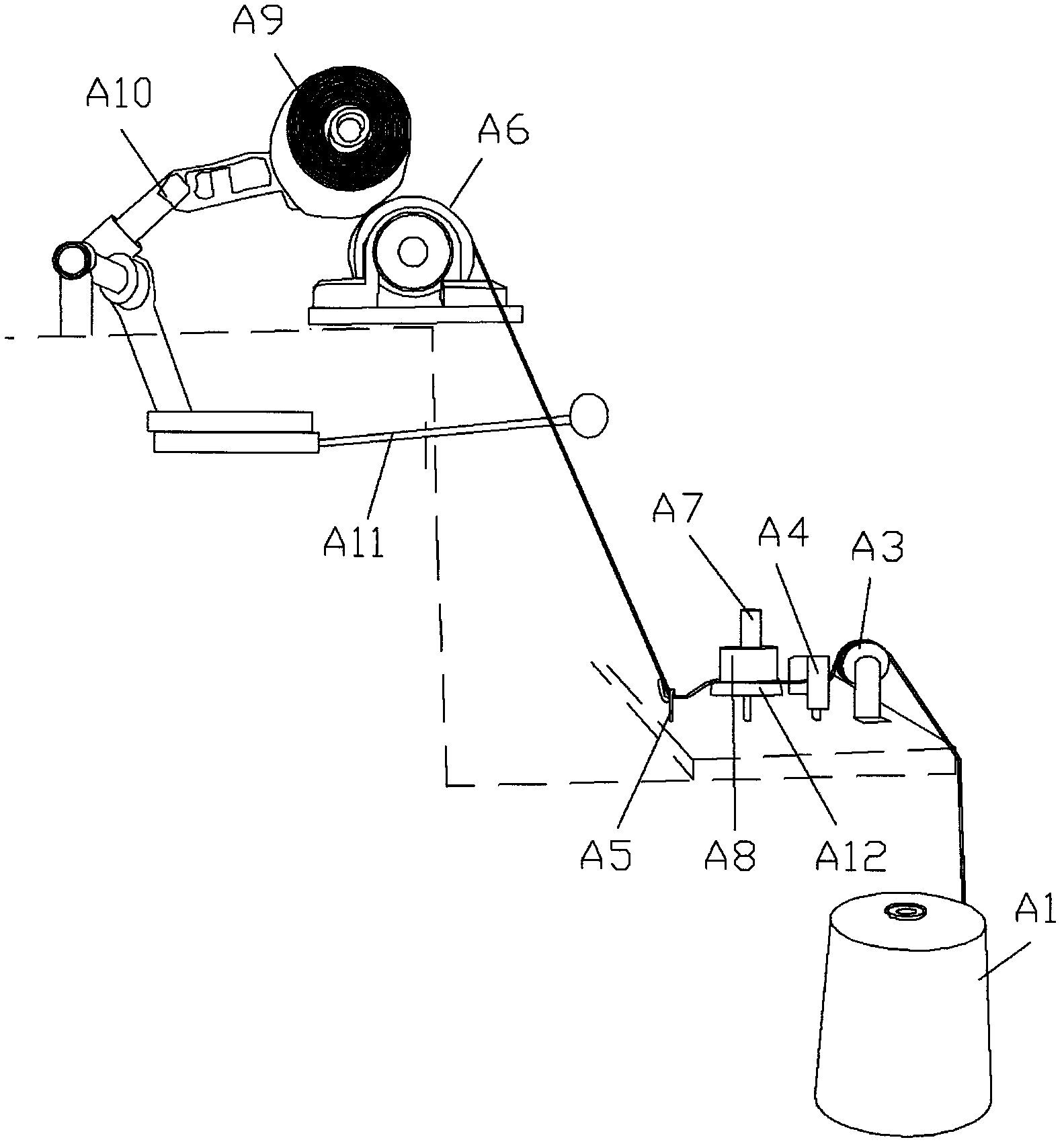

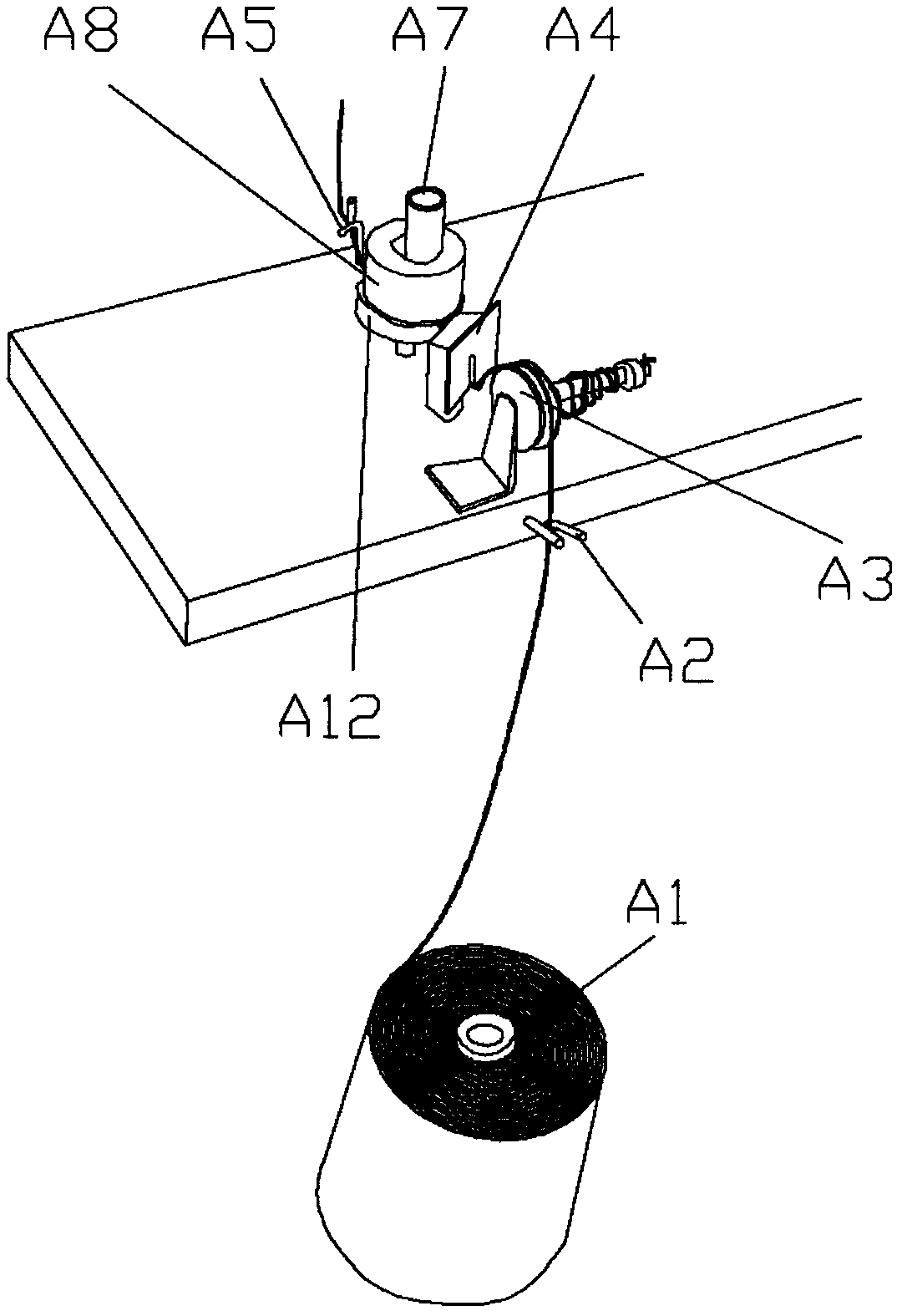

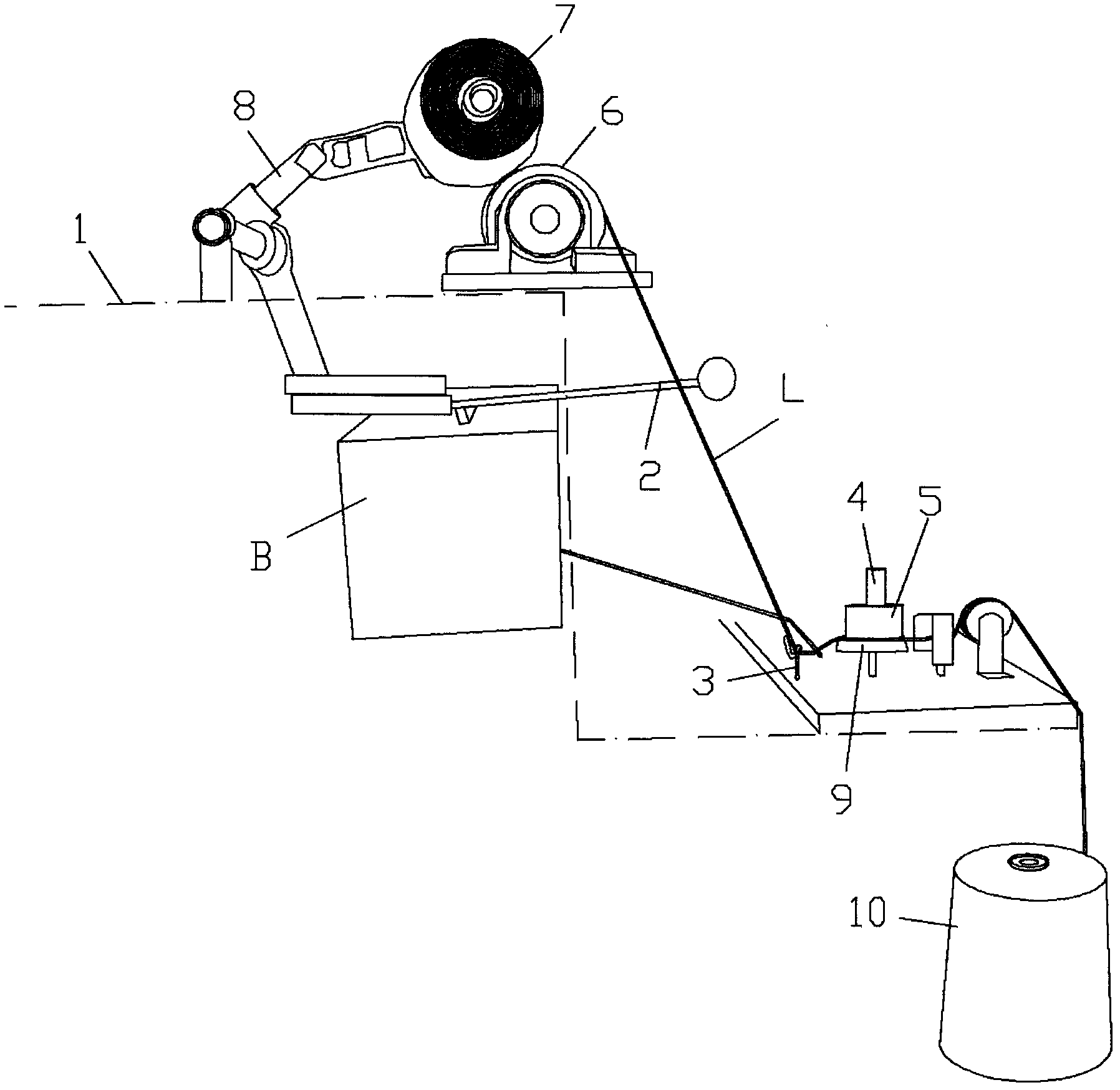

[0020] Example: see Figures 3 to 6 As shown in the figure, the device for automatically separating the drum from the broken bobbins of the drum doffing machine includes a frame 1 of the drum doffing machine, a manual separation lever 2, a rear thread lug 3, a waxing shaft 4, and a wax block 5. Groove drum 6, bobbin 7 and bobbin support 8, tray 9 is fixed on waxing shaft 4, wax block 5 is inserted and sleeved on waxing shaft 4, yarn L is clamped between tray 9 and wax block 5, The bobbin 7 is hinged on the bobbin support 8, and the separation device B is fixed on the frame 1. The structure of the separation device B is that a coil seat B2 is fixed on the shell B1, an electromagnetic coil B3 is fixed on the coil seat B2, and the electromagnet B4 is plugged in the electromagnetic wire diagram B3, the on-off switch B5 of the electromagnetic coil B3 is set on the shell B1, the folding trigger lever B6 is hinged on the shell B1, and one end of the first tension spring B7 acts on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com