Multifunctional efficient contact reactor

A reactor and multi-functional technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of high shear force and shear rate, affecting the effect of sedimentation treatment, and power consumption of the agitator, so as to save energy and improve The effect of the mixed reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

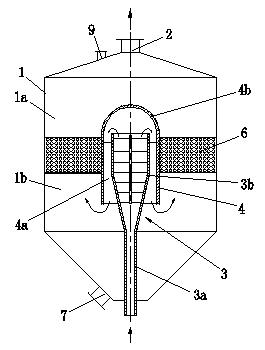

[0026] See attached picture. The present invention comprises a housing 1 with an inner cavity, the upper part of the housing 1 has a water outlet 2, and the inner cavity of the housing 1 is provided with a reaction device 3 communicated with a water inlet pipe and a distributing cylinder 4 with an open lower part;

[0027] The main body of the housing 1 is a cylindrical structure, and the upper and lower ends are conical structures;

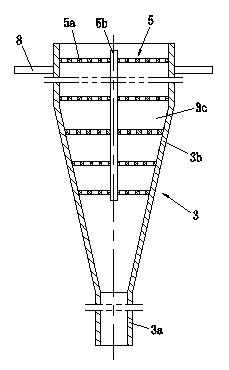

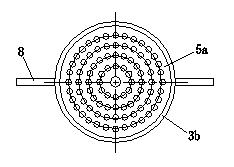

[0028] The reaction device 3 includes a water inlet pipe section 3a and a reactor body 3b connected to the water inlet pipe section. The reactor body 3b has an inner chamber 3c, and the upper part has an outlet. The upper part of the reactor body 3b is located in the distribution cylinder 4, There is a backflow passage 4a for water flow between the reactor body 3 and the cylinder wall of the distribution cylinder 4, and the outlet on the upper part of the reactor body 3b communicates with the backflow passage 4a and the opening at the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com