Coke oven coal leveling bar with pressing device

A compacting device and coke oven technology, which is applied in coke ovens, mechanical treatment of coal loaded into the furnace, petroleum industry, etc., can solve problems such as increasing the coke output and quality of a single furnace, low coke strength, and lack of compaction , to achieve the effect of increasing coke output and density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

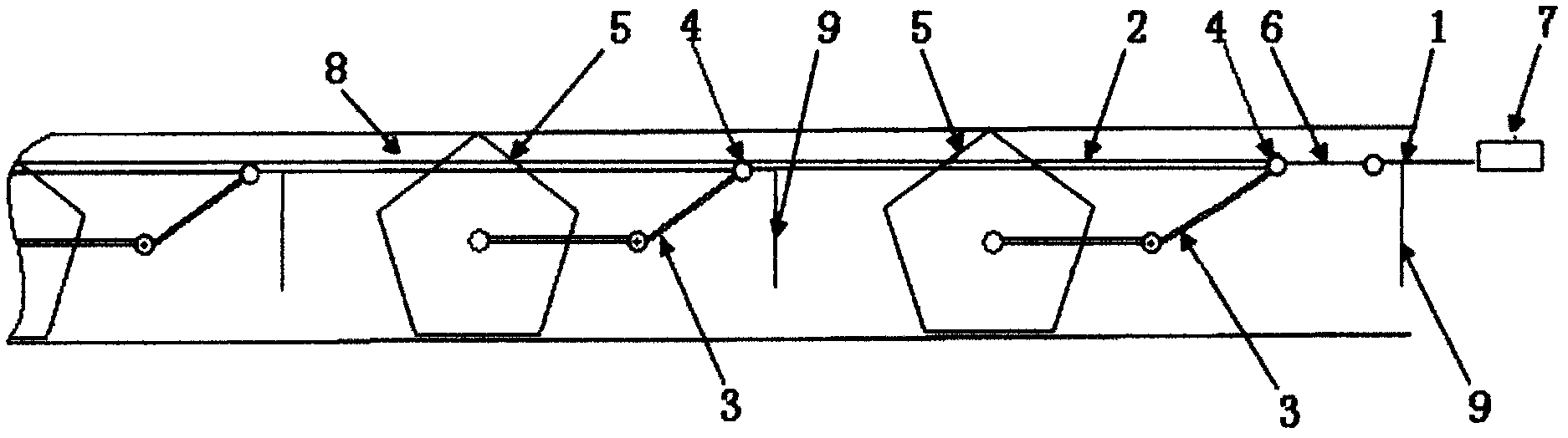

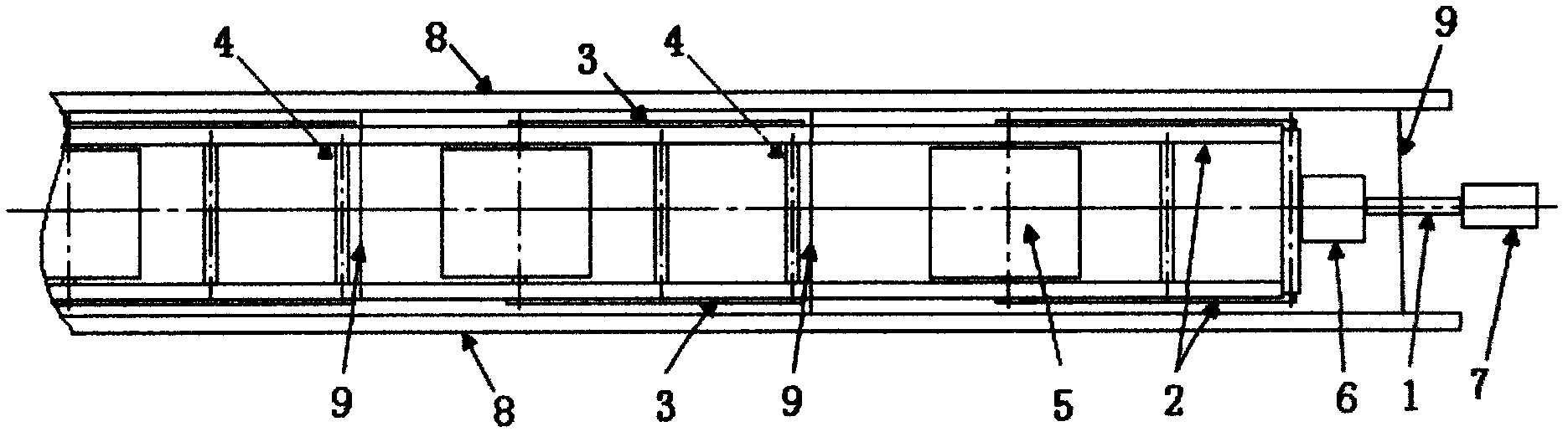

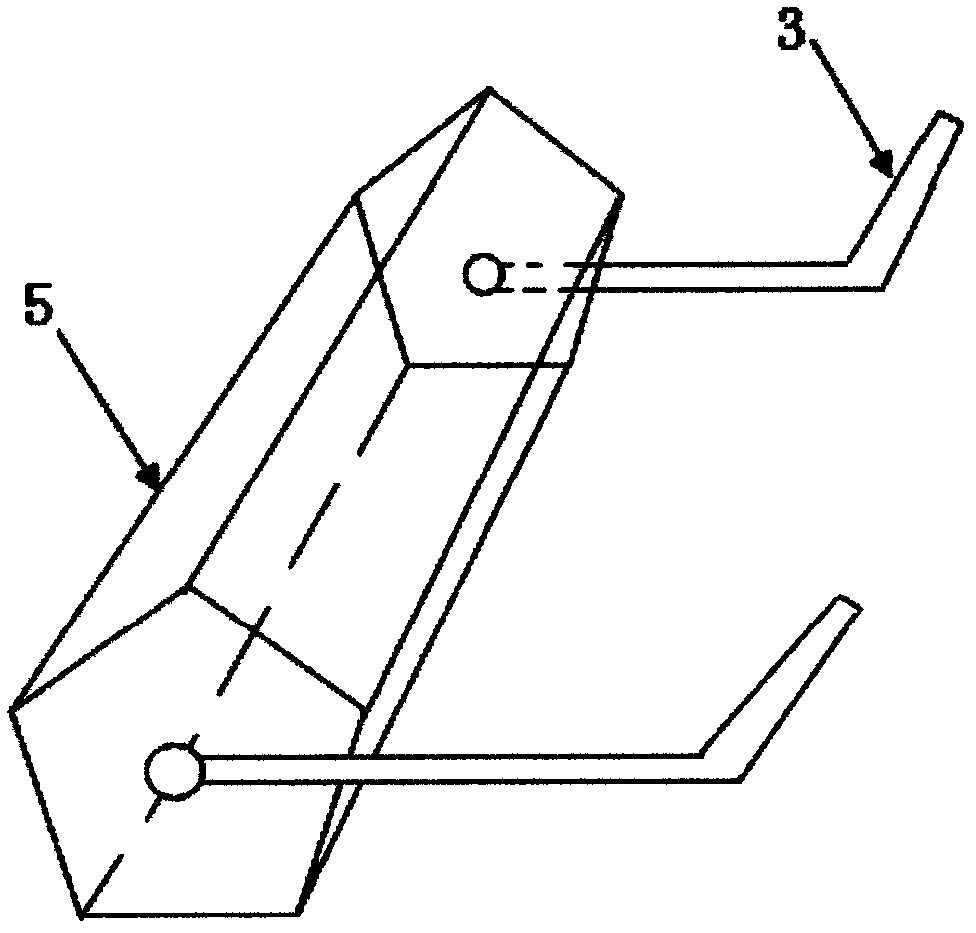

[0012] Embodiment: the present invention comprises side plate 8, and in side plate 8, is welded with reinforcing partition 9 (partition 9 plays flat coal and stabilizing effect), and by actuator 7, hydraulic rod 1, transmission rod 6, crank arm 3 , connecting rod 2, rolling member 5 and rotating shaft 4 form the pressing mechanism. The actuator 7 is a hydraulic action cylinder that is controlled by a hydraulic console and a computer. The actuator 7 is installed after the hydraulic rod 1 is pushed out, and the hydraulic rod 1 slides against the partition 9 and pushes the transmission rod 6 forward so that The crank arm 3 rotates, drives the crank arm 3 lower ends to press down, and at this moment the rolling part 5 that is connected with the crank arm 3 lower ends compresses the loose coal heap downwards. Rolling parts 5 are equilateral pentagons, and these rolling parts 5 hold-down devices need to install four groups to six groups on the flat coal rod. After these rolling par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com