White wine pit liquid fermenting tank

A fermenter and solid state fermenter technology, applied in the field of liquor solid state fermenter, can solve the problems of poor environment, difficult collection, troublesome yellow water collection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

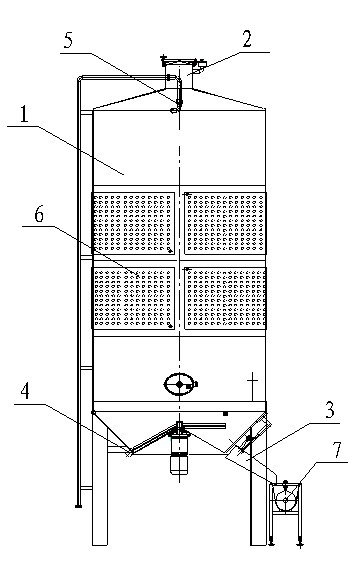

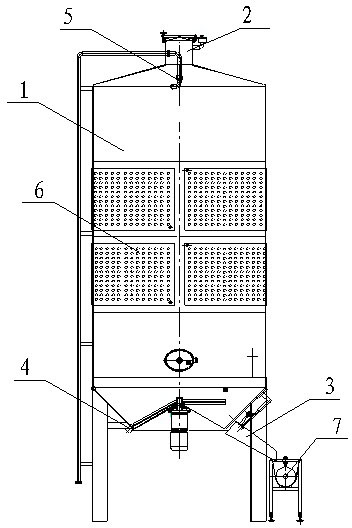

[0015] Such as figure 1 As shown, the present invention comprises a tank body 1, the upper part of the tank body 1 is provided with a material inlet 2, the lower part of the tank body is respectively provided with a solid discharge port 3 and a liquid discharge port 4, and the upper part of the tank body 1 is provided with a spraying device 5. A jacket 6 is provided on the outer wall of the tank body 1 .

[0016] The present invention can have the following working process: now, according to the ambient temperature of the brewing workshop, it is judged whether it is necessary to use the jacket 6 to cool down the fermenter tank body 1, and then the fermented grains mixed with koji are poured into the fermenter from the feed port 2 After that, the microbial cellar liquid extracted from the pit mud is sprayed on the wine grains through the spraying device, and the wine grains are fermented in the fermenter. After the fermentation is completed, the liquid materials such as yellow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com