Animal cell fermentation and separation all-in-one machine

An animal cell and animal cell culture technology, applied in the field of an integrated machine for fermentation and separation of animal cells, can solve the problems of cumbersome operation, difficulty in realizing full utilization of animal cells, reducing the yield of supernatant liquid and production efficiency, etc., so as to improve production The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

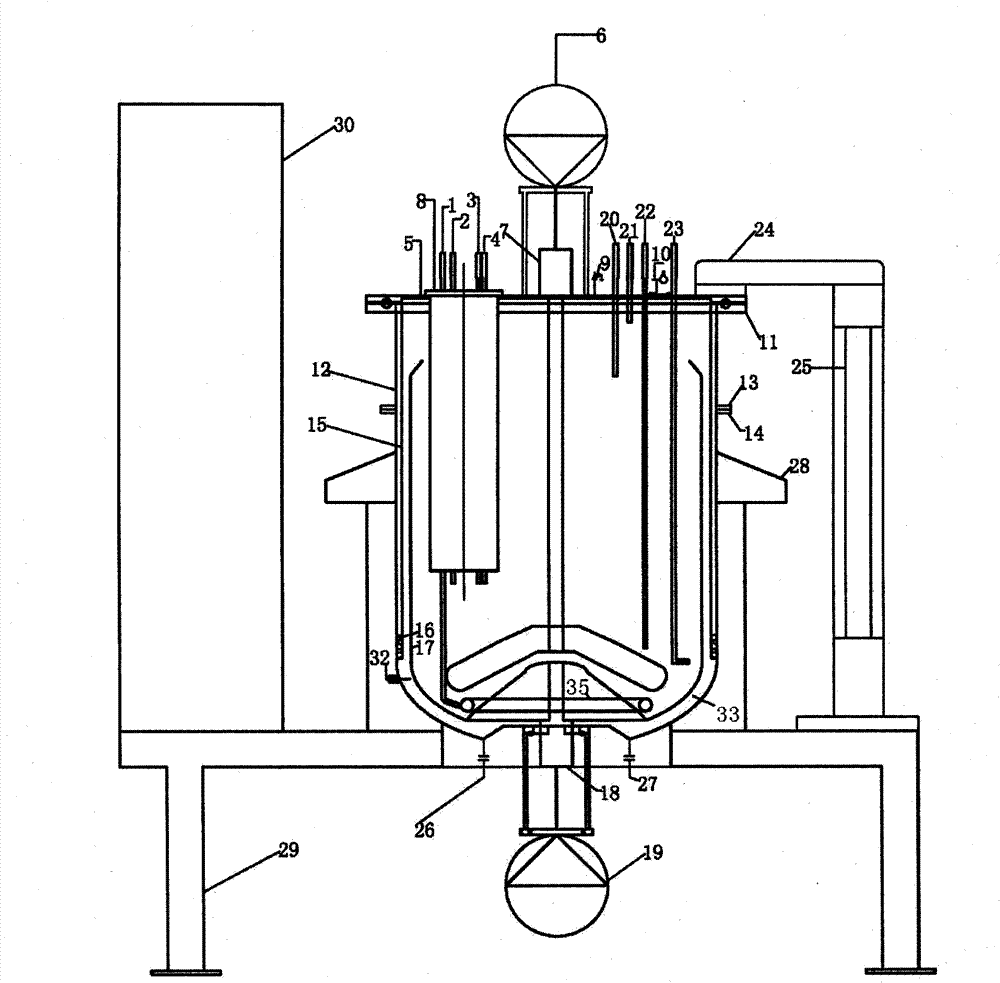

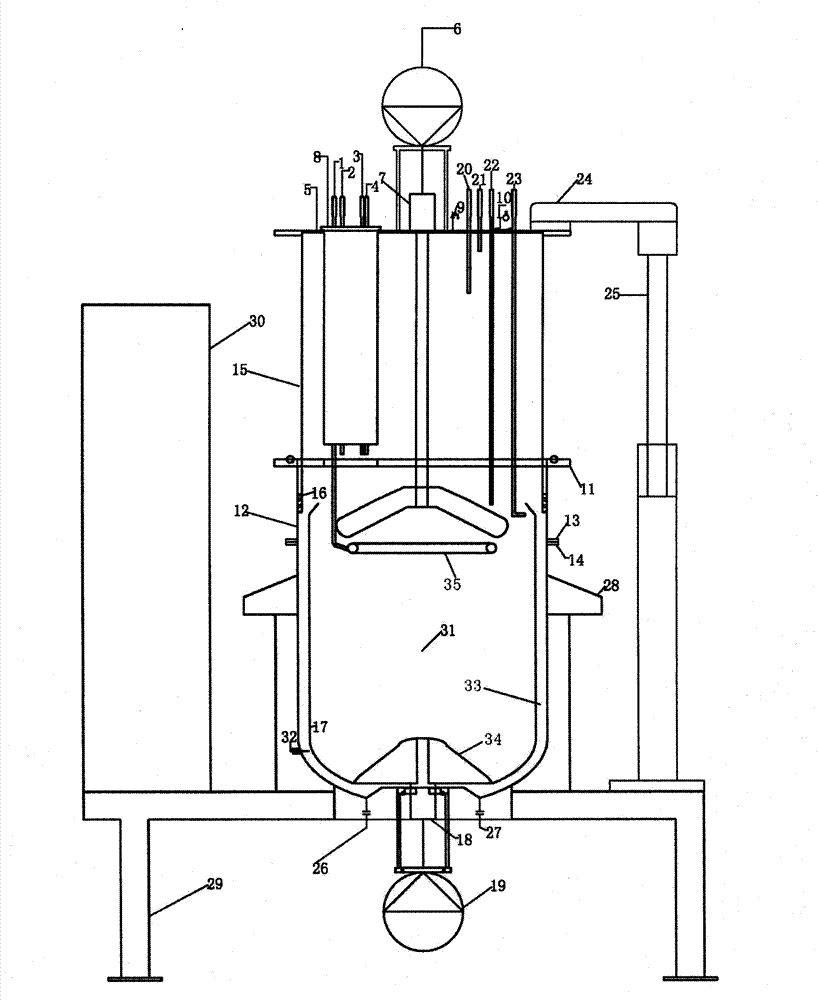

[0012] Combined with the accompanying drawings:

[0013] 1) if figure 1 , when the hydraulic device is in the initial reset state, the 12 outer tank body is compounded with the content space of the 17 inner tank body, and the volume space is used as a space for cell culture. Through 1 gas filling port, 2 temperature sensor, 3 dissolved oxygen sensor, 4 pH sensor, 6 culture stirring motor, 7 mechanical seal, 8 sensor protection sheath, 9 safety valve, 10 sight glass, 20 material filling port, 21 Exhaust gas outlet, 22 Sampling port, 32 Insulation jacket liquid level gauge, 33 Insulation jacket, 35 Annular air distributor constitutes a dedicated system for cell culture reactors, and the cell culture is completed after about 7-11 days of culture cycle fermentation process. Among them, 1 gas filling port, 21 tail gas discharge port pneumatic valve, 2 temperature sensor, 3 dissolved oxygen sensor, 4 pH sensor, 6 cultivating stirring motor are controlled by computer program in 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com