Sludge-rapidly-fermented fertilizer making or soil making pipe system

A pipeline system and sludge technology, applied in the direction of sewage/sludge fertilizer, sludge treatment, biological sludge treatment, etc., can solve the problems of high energy consumption, low economic benefits, and long treatment cycle of sludge treatment, and achieve Small footprint, good effect and fast fermentation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

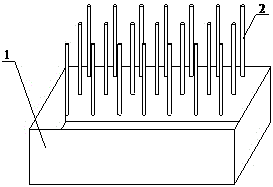

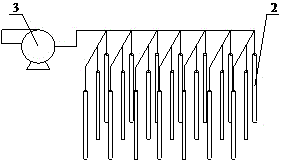

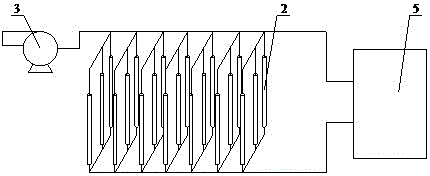

[0023] Such as figure 1 As shown, the pipeline system of the present invention includes a plurality of preset pipes 2, and the preset pipes 2 are distributed in the sludge fermentation place 1 of sludge. Such as Figure 4 , Figure 5 As shown, the single preset pipe 2 is a single pipe, double casing or multi-pipe structure, and at least includes one aeration pipe 2a, and the aeration pipe 2a is a hollow with a plurality of air holes on the side wall. Tube. When the preset pipe 2 is a single pipe structure, the preset pipe 2 is the aeration pipe 2a. When the preset pipe 2 has a double casing structure, one of which is an aeration pipe 2a, a protective pipe 2c may be provided outside the aeration pipe 2a or a heating pipe 2b may be provided inside the aeration pipe 2a. When the preset pipe 2 has a three-pipe structure, one of which is an aera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com