Water electrolysis hydrogen production method

A technology of water electrolysis and hydrogen production equipment, applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of system gas production efficiency decline, affect equipment life, and affect system production, so as to improve equipment operation efficiency and hydrogen production capacity , Reduce the effect of equipment maintenance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

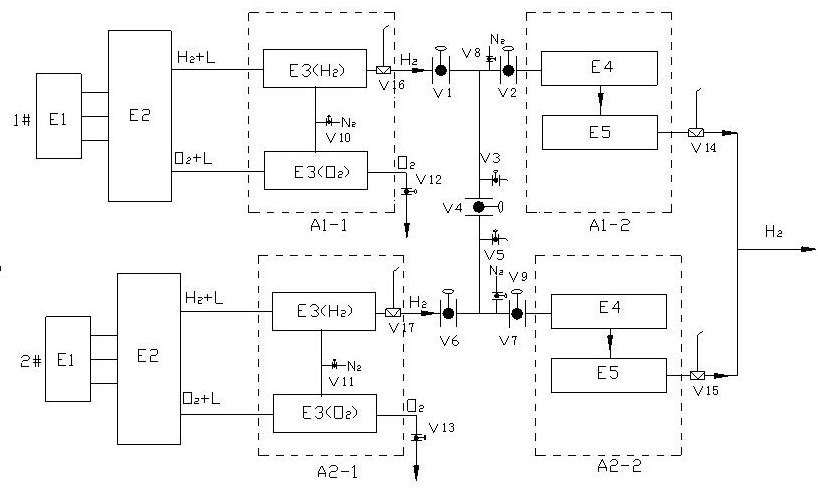

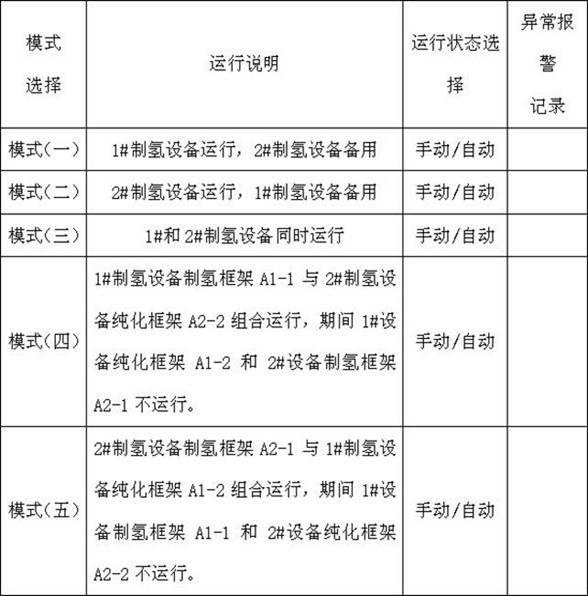

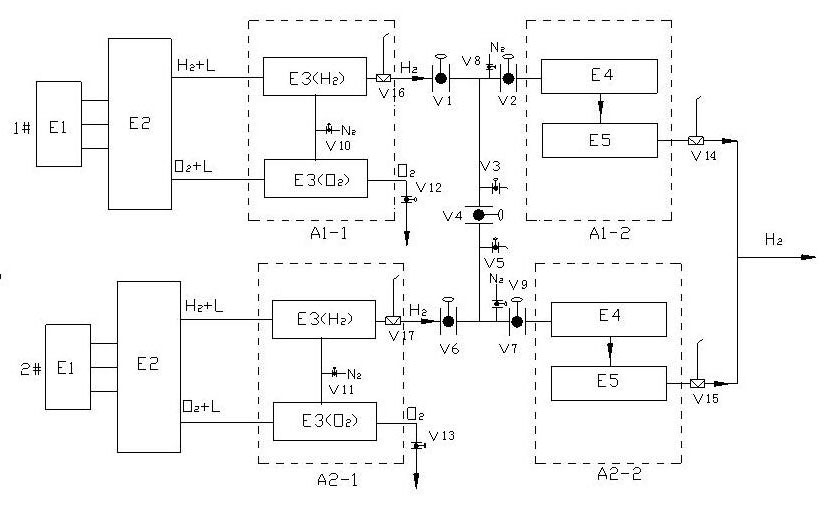

[0029] Example: figure 1 As shown, the water electrolysis hydrogen production equipment of the embodiment of the present invention includes two sets of water electrolysis hydrogen production equipment, namely 1# hydrogen production equipment and 2# hydrogen production equipment, and the hydrogen production framework (A1-1) of the 1# hydrogen production equipment and the The hydrogen pipeline between the purification frame (A1-2) is equipped with valves V1 and V2, which are used as the shut-off valves of the two frames of the 1# hydrogen production system; the hydrogen production frame (A2-1) of the 2# hydrogen production equipment and the purification frame (A2 -2) Set valves V6 and V7 in the hydrogen pipeline between them, as the cut-off of the two frames of the 2# hydrogen production system.

[0030] The 1# hydrogen production equipment and 2# hydrogen production equipment both include a silicon rectifier (E1), a water electrolyzer (E2), a hydrogen production frame (A1-1, A2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com