Urban road water permeability cement concrete pavement structure and construction process thereof

A cement concrete and water permeability technology, which is applied to the coagulation pavement, roads, roads and other directions of on-site paving, can solve the problems of climate deterioration, high temperature, heat island effect, etc., and achieve reasonable structural design, convenient construction, and enhanced water permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

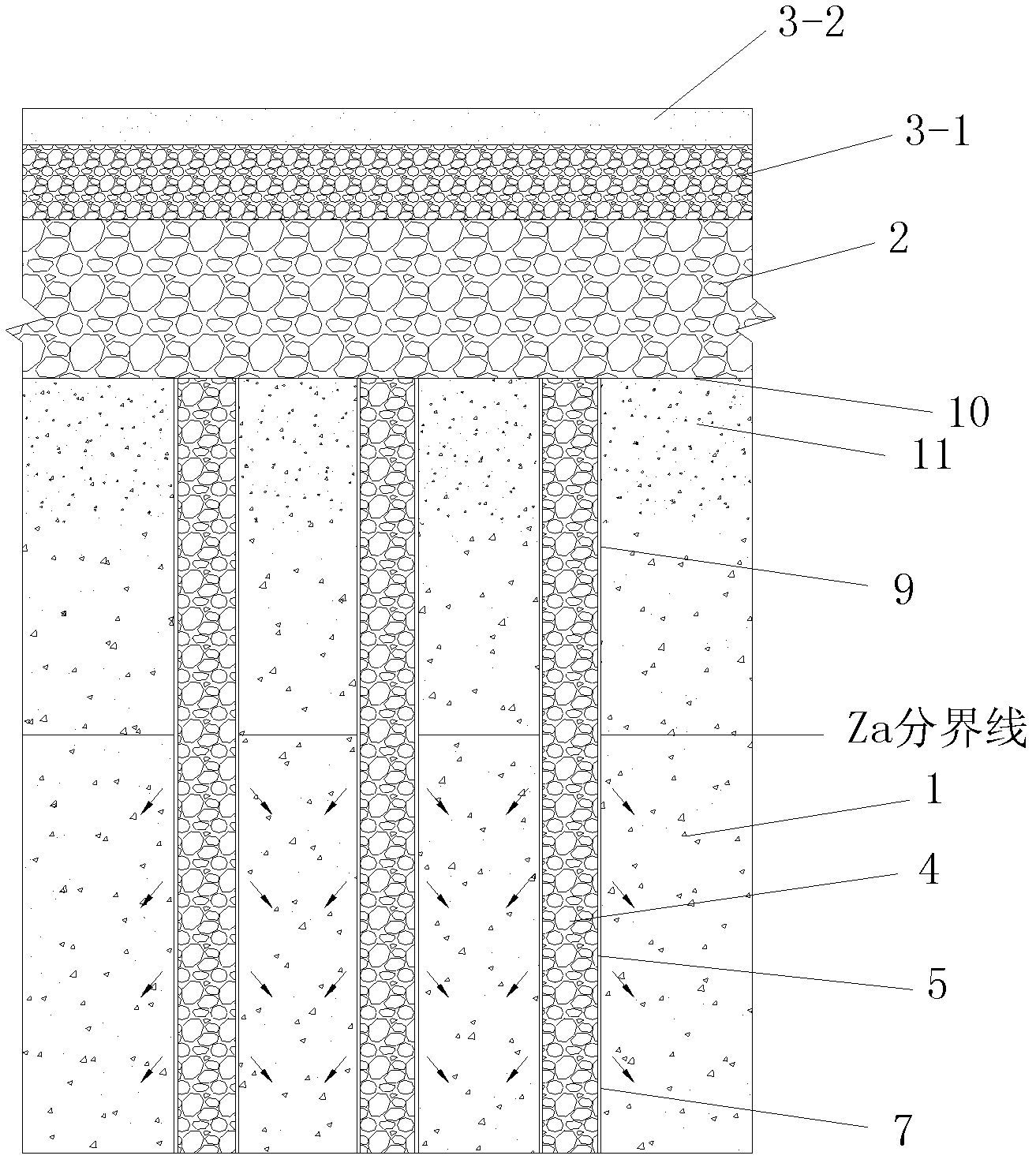

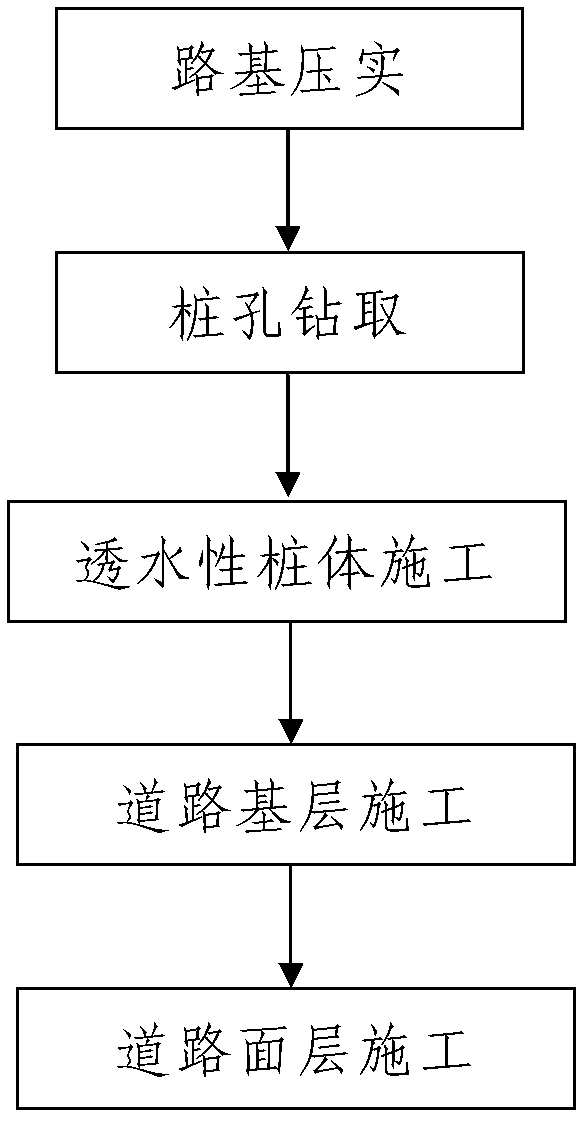

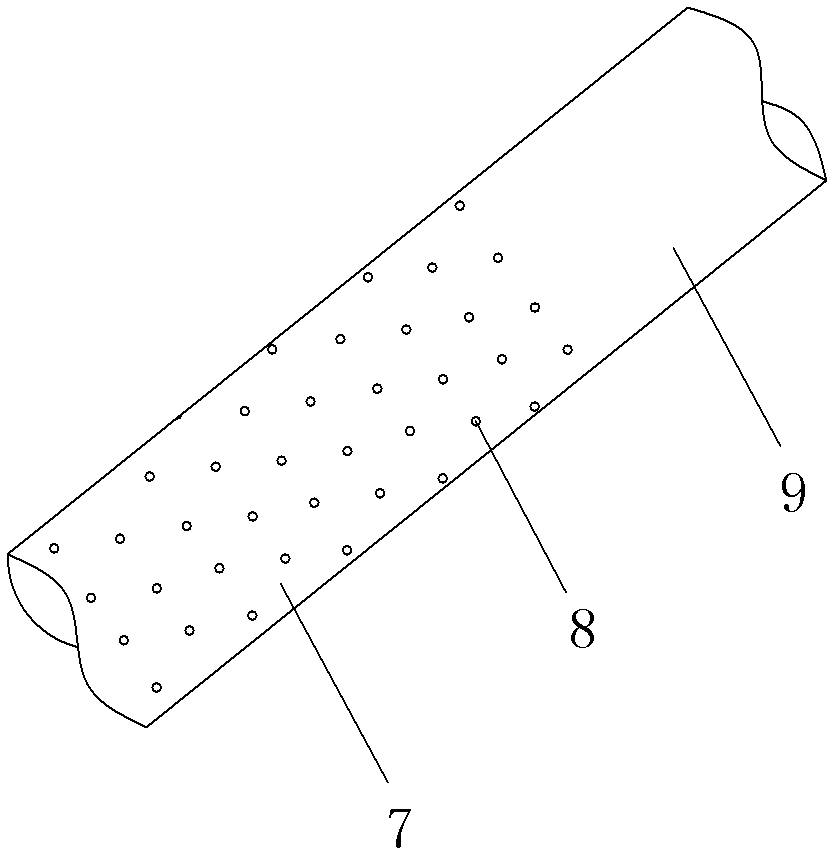

[0049] like figure 1 A permeable cement concrete pavement structure for an urban road as shown, comprising an asphalt-stabilized drainage base 2 paved on the roadbed and paved with asphalt-stabilized crushed stones, and a road surface layer paved on the asphalt-stabilized drainage base 2 . The road surface layer is a road surface layer 1 or a road surface layer 2 consisting of a lower layer 3-1 and an upper layer 3-2 paved on the lower layer 3-1, and the road surface layer 1 is a large gap. Graded drainage asphalt wear layer or porous cement concrete pavement pavement layer paved with porous cement concrete pavement material, the upper layer 3-2 is paved with porous cement concrete pavement material or is open graded with large voids A drainage-type asphalt wear layer is provided, and the lower layer 3-1 is a large-void open-graded drainage-type asphalt wear layer. A plurality of water-permeable piles with the same structure and size are arranged inside the roadbed, and a pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wet density | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com