Large-volume seamless gas cylinder rotating-prevention fixing device for large-pipe trailer

A fixed device, large-volume technology, applied in container filling method, container discharge method, gas/liquid distribution and storage, etc., can solve problems such as safety hazards and natural gas leakage in gas cylinders, avoid leakage and eliminate safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

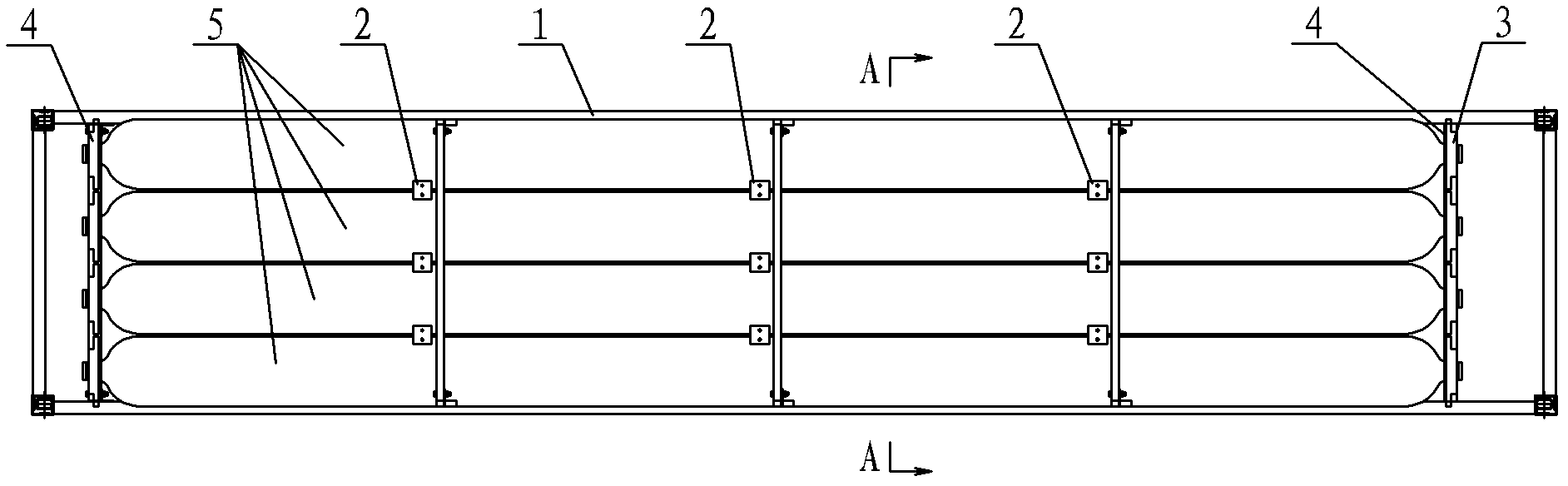

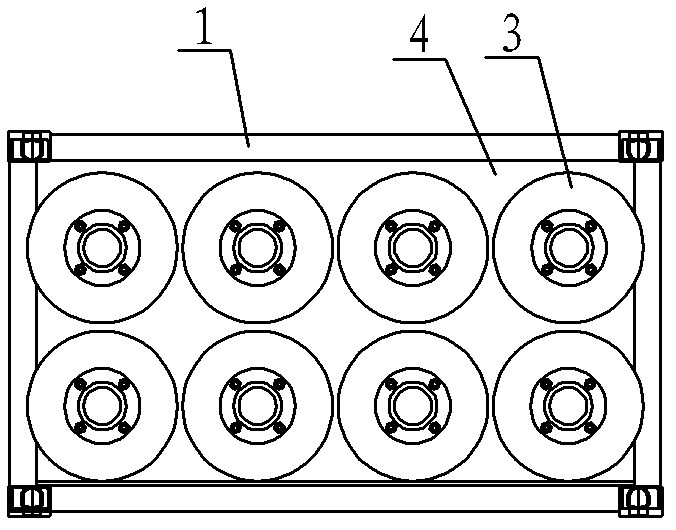

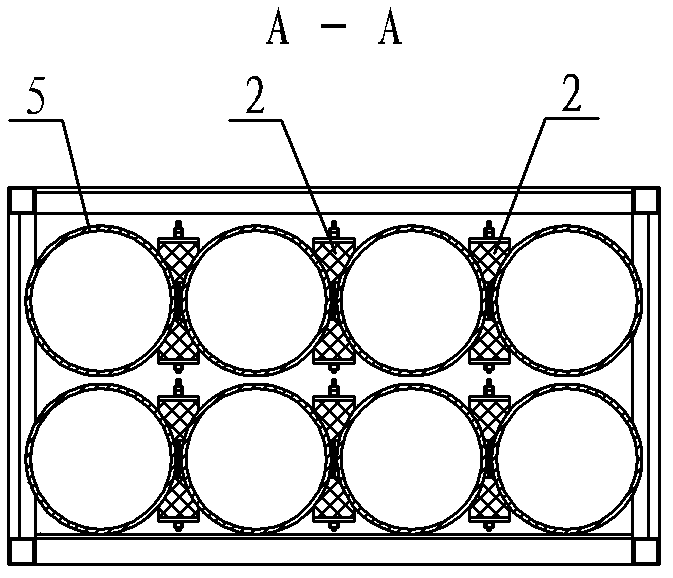

[0007] Specific implementation mode one: combine Figure 1 ~ Figure 4 Describe this embodiment, the large-volume seamless gas cylinder anti-rotation fixing device for a large-tube trailer in this embodiment includes a container frame 1, two flange fixing frames 4, several pressing devices 2 and several flanges 3, each A hold-down device 2 comprises a connection block 2-1, two rubber piers 2-2, two pressing plates 2-3, four bolts 2-4 and four first nuts 2-5, each rubber piers 2-2 Consisting of a frustum 2-2-1 and a square seat 2-2-2, the bottom surface of the large end of the frustum 2-2-1 is connected with the end face of the seat 2-2-2, and the frustum 2-2-1 is connected with the The square seat 2-2-2 is made into one body, the conical surface of each cone 2-2-1 is a concave arc surface, and the two rubber piers 2-2 are symmetrical based on the center line N-N of the connecting block 2-1 Set at both ends of the connecting block 2-1, two threaded holes 2-2-3 are provided on t...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination Figure 4 To describe this embodiment, the material of each rubber pier 2-2 in this embodiment is polyurethane. This material does not damage the outer wall of the gas cylinder 5 . Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination Figure 4 To describe this embodiment, the distance t between the end faces of the two rubber piers 2-2 on the pressing device 2 of this embodiment is 50 mm to 100 mm. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com