Dry heating protection control method for liquid electric heater

A technology of electric heater and control method, applied in fluid heaters, lighting and heating equipment, etc., can solve the problems of slow response of mechanical thermostat, high protection temperature, uncertain protection time, etc., to save temperature sensors, reduce The requirements of control accuracy and the effect of accurately controlling the dry burning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with embodiment the present invention is further described.

[0015] A control method for dry burning protection of a liquid electric heater, comprising the following steps:

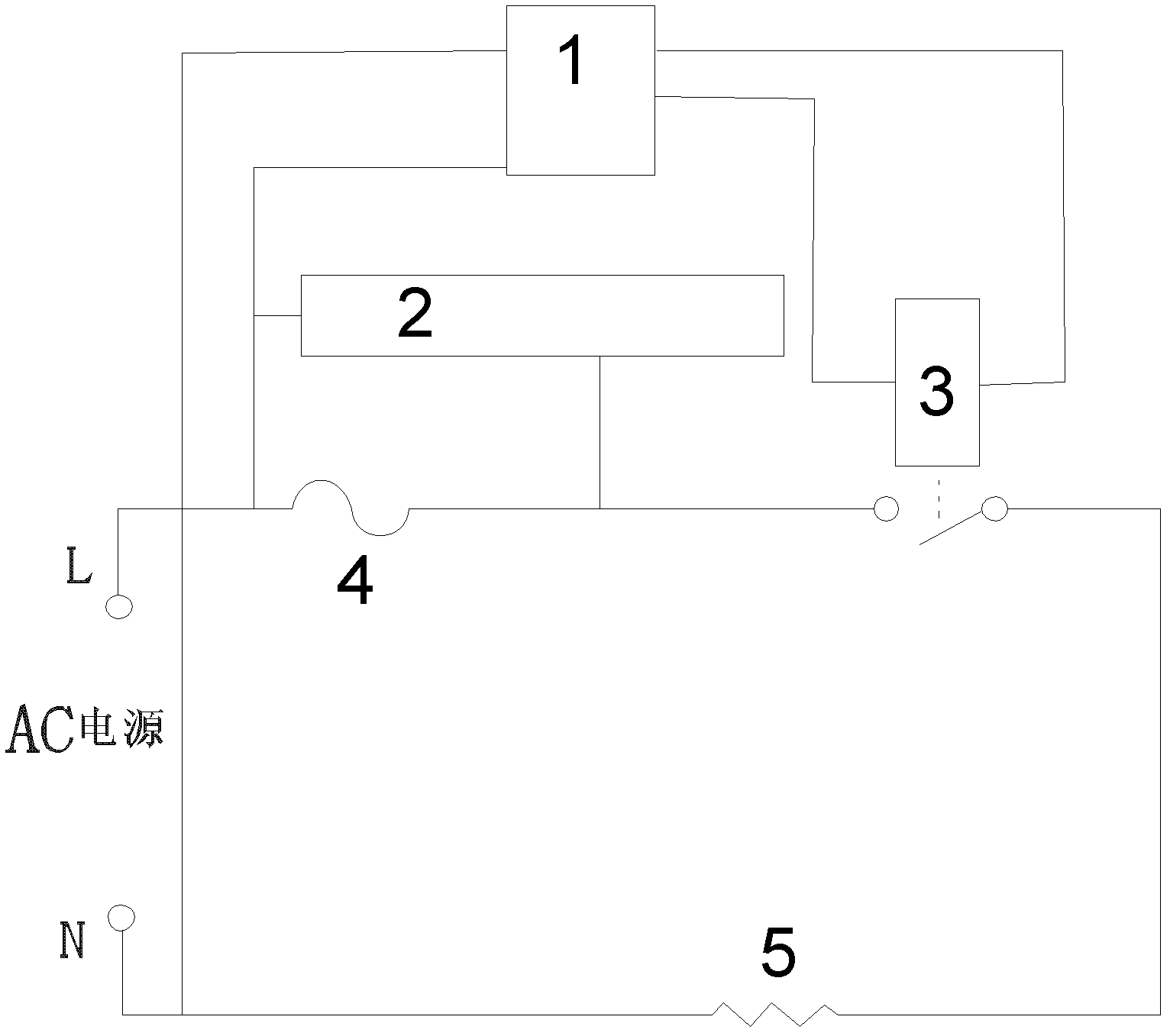

[0016] A. Install a temperature controller on the liquid electric heater, connect the temperature controller in series with the heating element of the heater and the control relay, and install a detection module at both ends of the temperature controller to detect its on-off;

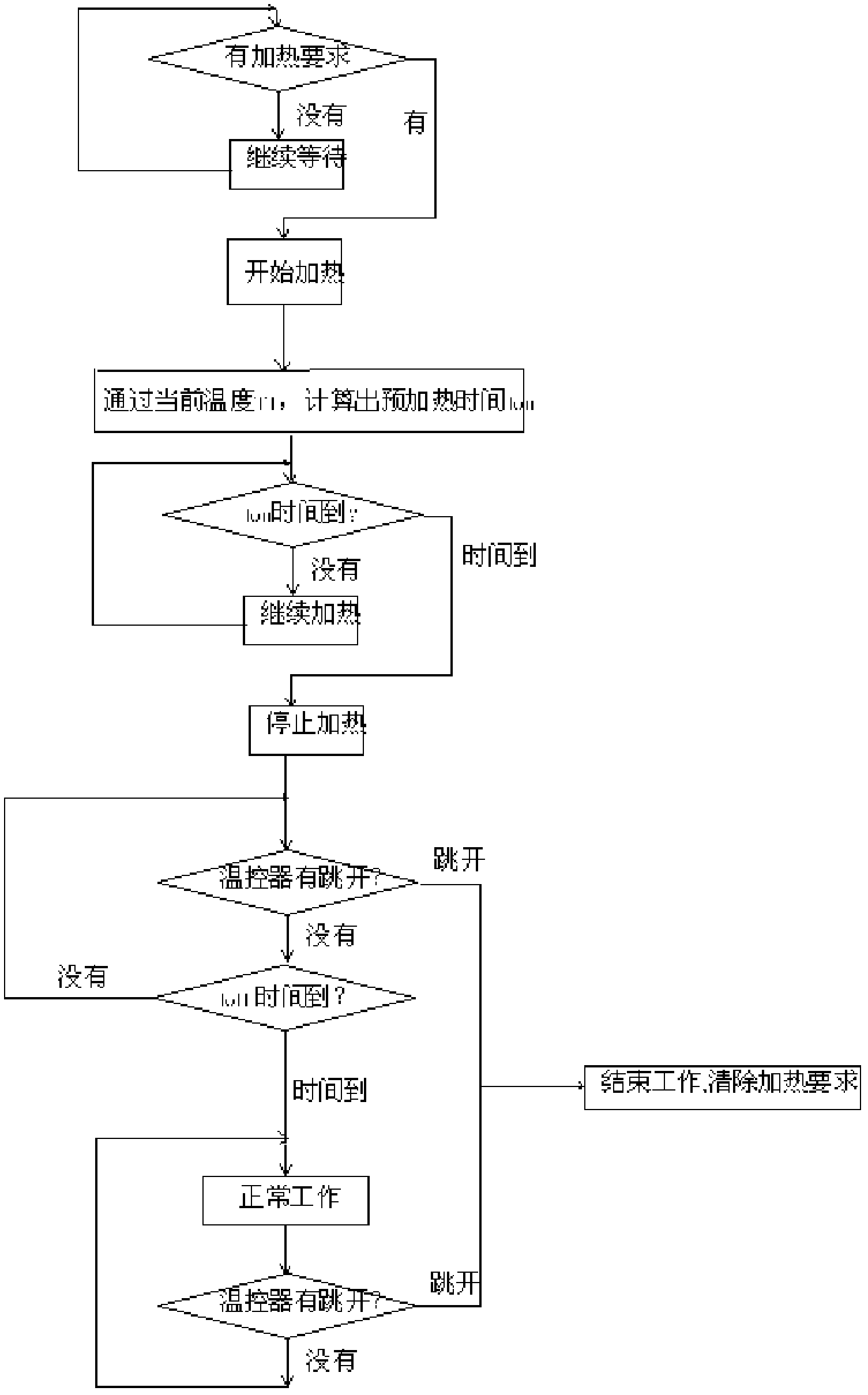

[0017] B. The microprocessor is controlled by the program. When starting the liquid heater to heat, first perform a short-term heating program, that is, let the heating element of the heater heat for a short time, and then stop heating for a short time; short-time heating and stop time It is determined according to the power of the heating element itself, the volume and density of the heating element, the specific heat capacity of the heating element, and the temperature to be protected;

[0018] C. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com