On-line engine cylinder hexahedral hole set position error detecting method

An engine cylinder block and detection method technology, applied in the fields of visual inspection and mechanical quantity measurement, can solve the problems of low detection efficiency, high cost, difficult application, etc., and achieve the effect of fewer cameras, high degree of automation, and high measurement efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

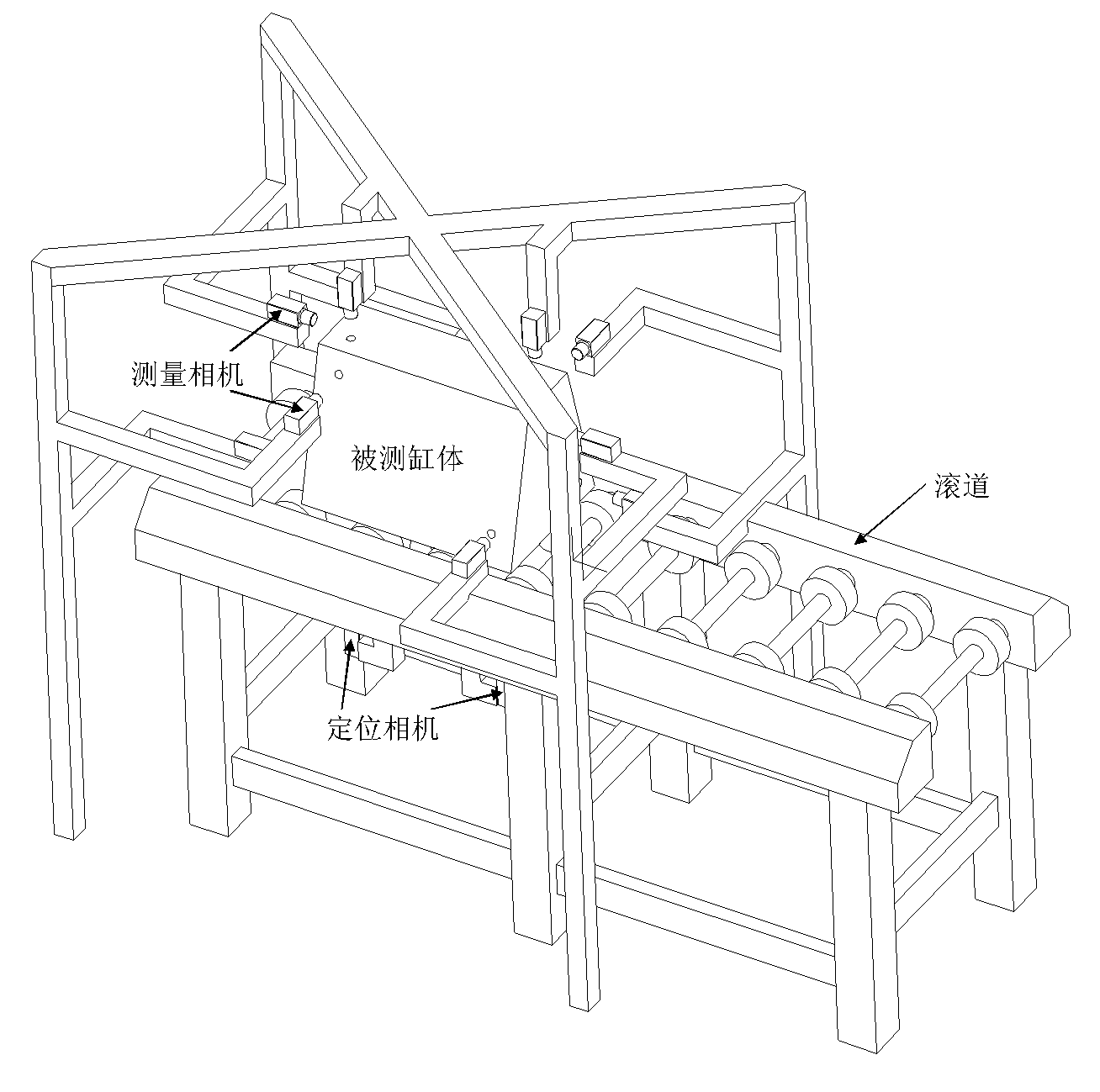

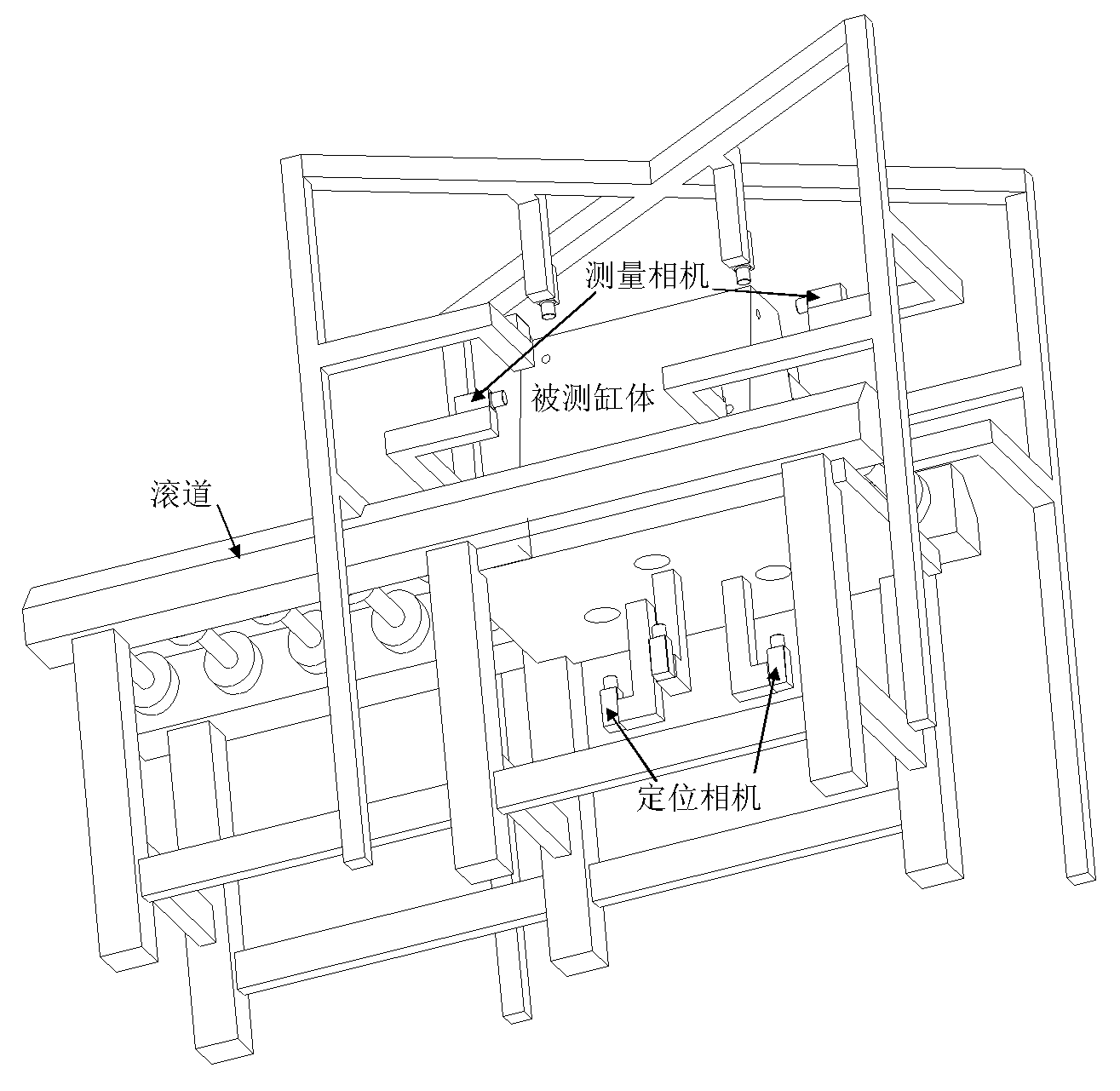

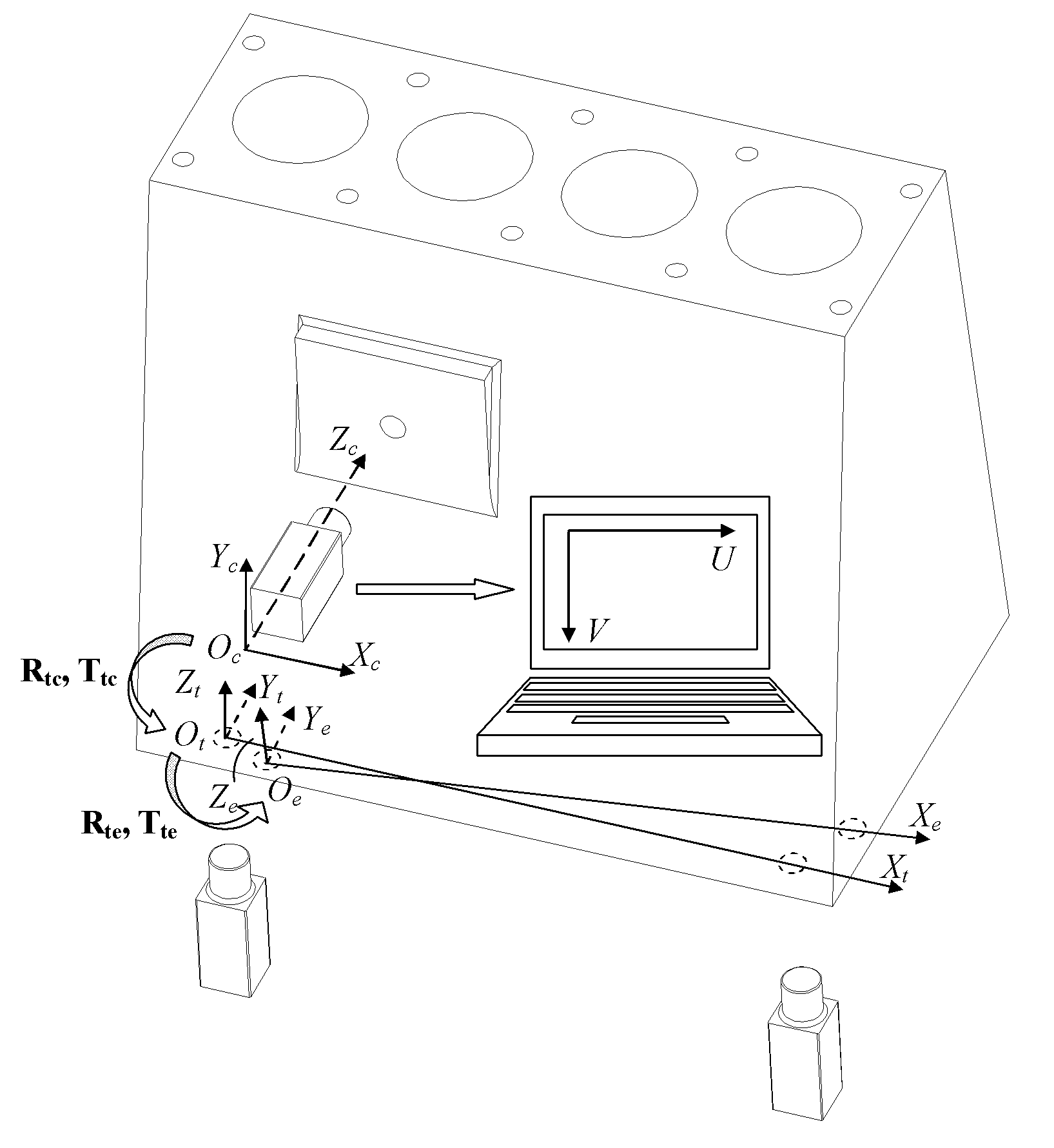

[0024] When machining the engine block, first process the bottom plane and the two positioning pin holes on the bottom plane, and process the rest of the surface and hole groups based on this, that is, the engine block is based on "one side with two pins". During the sampling inspection of the cylinder block, the positional relationship between each hole and the two pins on one side is also checked to verify whether the cylinder block is qualified. Therefore, when measuring the cylinder, it is first necessary to locate the cylinder, that is, to establish the reference coordinate system of the cylinder. Due to errors in the processing of positioning pin holes, the positioning accuracy is not high when using traditional mechanical positioning methods, which directly affects the final measurement accuracy. The invention uses two area array cameras to image two positioning pin holes on the bottom surface of the cylinder respectively, monitors the variation of the positioning refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com