Optical encoder

A technology of optical encoders and optical disks, applied in the field of optical encoders, can solve the problems of limited optical encoder application range, short service life, poor temperature resistance limit, etc., and achieve the goal of increasing light utilization, increasing life, and reducing brightness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

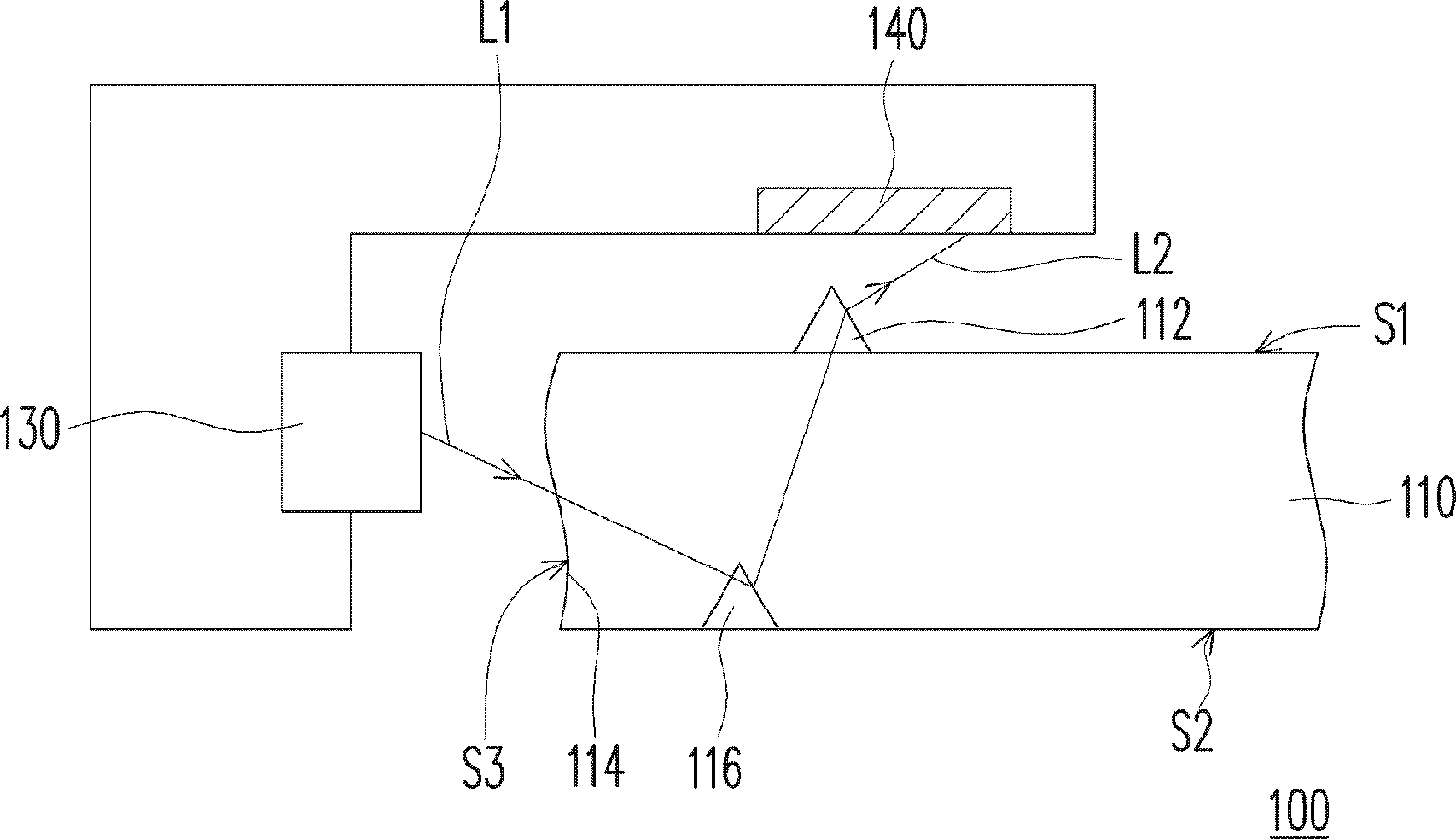

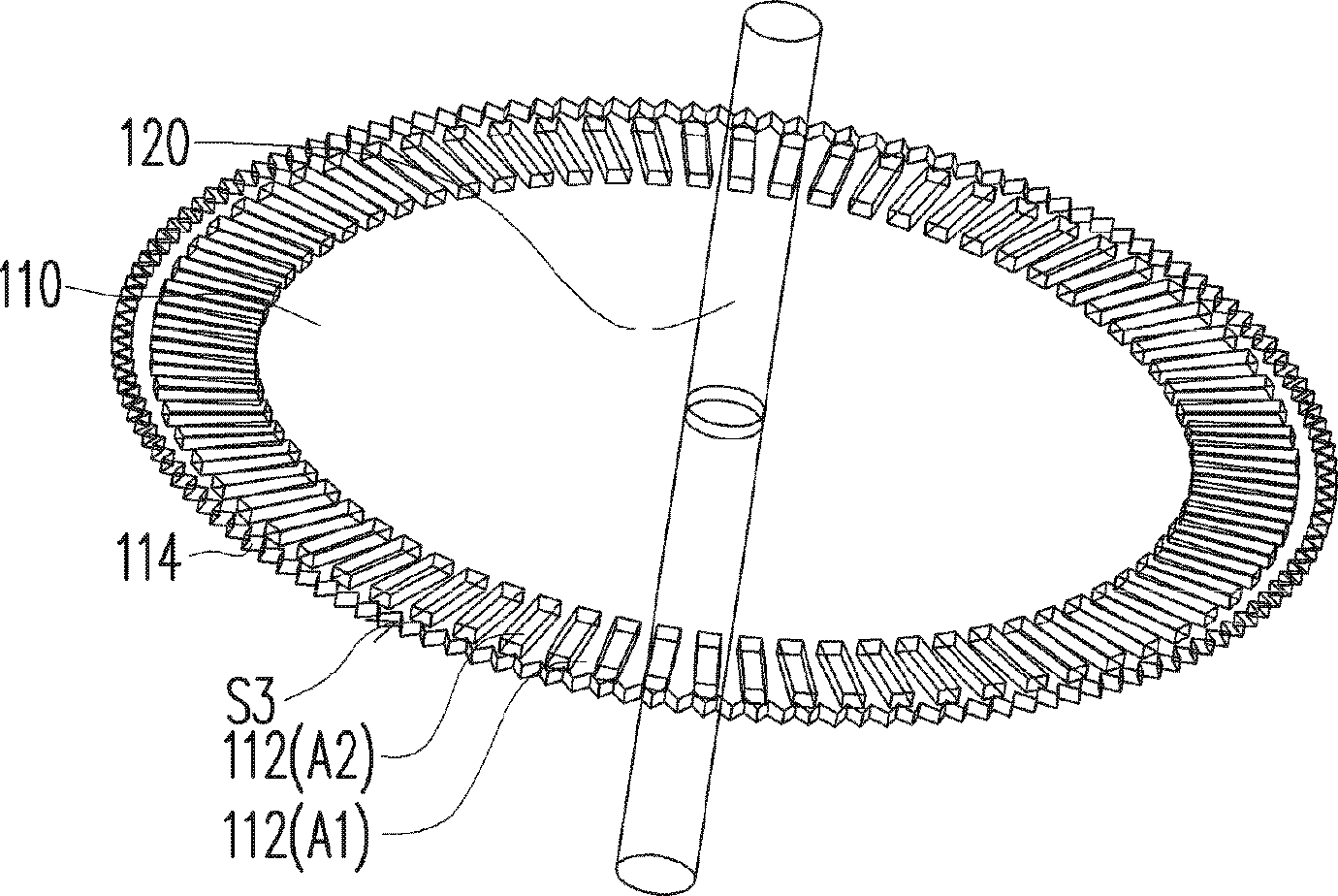

[0051] Figure 1A It is a schematic side view of the optical encoder according to the first embodiment of the present invention. Figure 1B for Figure 1A Schematic top view of a medium optical disc.

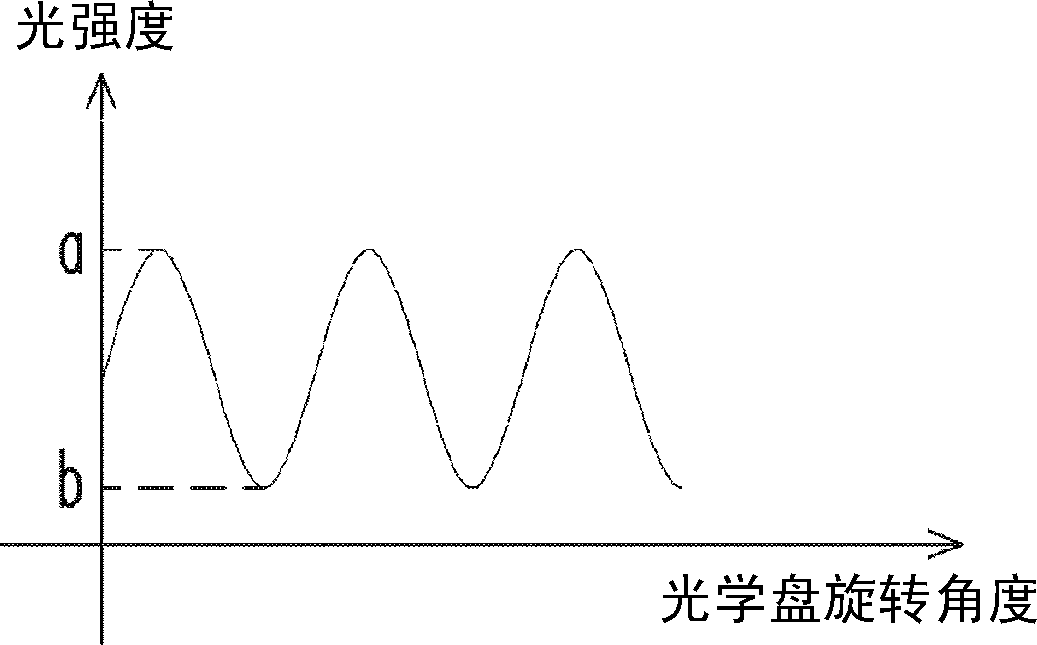

[0052] Please refer to Figure 1A and Figure 1B , the optical encoder 100 of this embodiment includes an optical disk 110 , a shaft 120 , a light source 130 and a sensor 140 . In this embodiment, the optical disc 110 is, for example, a disk-shaped optical disc. In addition, the material of the optical disk 110 is, for example, polycarbonate (PC), acrylic (Polymethyl methacrylate, PMMA) or dacron (polyethylene terephthalate, PET) and other transparent polymer materials. Specifically, the optical disc 110 has a first surface S1, a second surface S2 opposite to the first surface S1, a side surface S3 connected between the first surface S1 and the second surface S2, and a plurality of The first optical structure 112 of S1.

[0053]In addition, the optical disk 110 further inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com