Cycle testing device and testing method for motor positive and negative rotation power module

A technology of cycle test and test method, which is applied in the direction of motor generator test, etc., can solve the problems of waste of manpower, difficult to achieve accurate and consistent control of execution time, etc., and achieve the effect of convenient and accurate setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

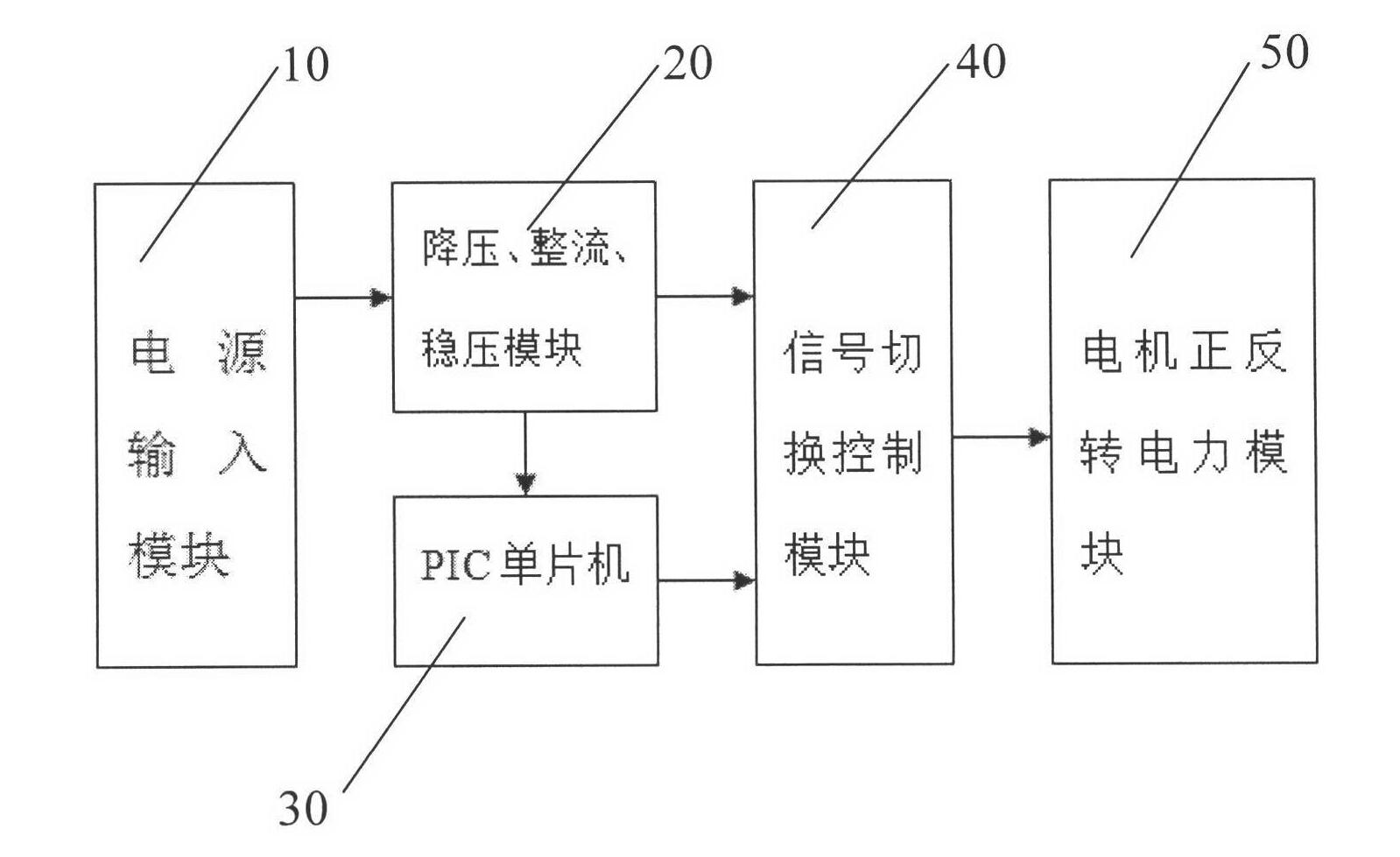

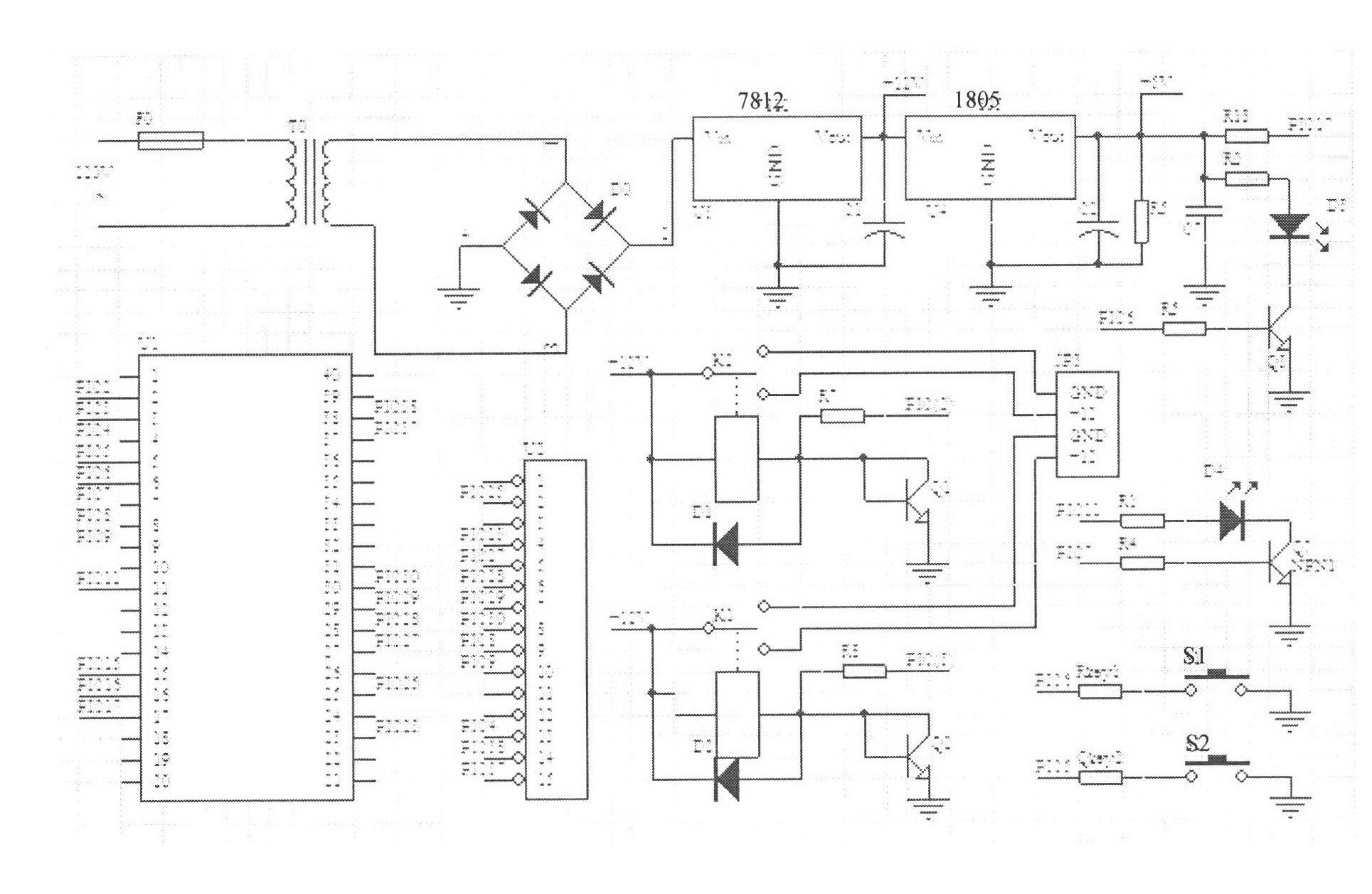

[0015] Such as figure 1 As shown, the motor forward and reverse power module cycle test device of the present invention includes a test power input module 10, a step-down, rectification, voltage stabilization module 20, a PIC microcontroller 30, and a signal switching control module 40; the power input module 10 Voltage provides the operating voltage of PIC single-chip microcomputer 30 and signal switching control module 40 after voltage step-down, rectification, voltage stabilizing module 20, and described PIC single-chip microcomputer 30 is connected with signal control module 40, and described and signal switching control module 40 is connected with to-be-tested The forward and reverse rotation of the motor is connected to the power module, and the PIC microcontroller 30 is used to control the timing switching of the forward and reverse input signals of the motor. In another embodiment, the PIC microcontroller presets a variety of cycle test modes to match the test requirem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com