Method for manufacturing optical diaphragms and method for manufacturing stereoscopic displays

The technology of an optical film and its manufacturing method is applied in optics, optical components, nonlinear optics, etc., and can solve problems such as weak secondary alignment force, color shift, and image quality effects of stereoscopic displays, so as to improve color shift and improve The Effect of Stereoscopic Image Quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

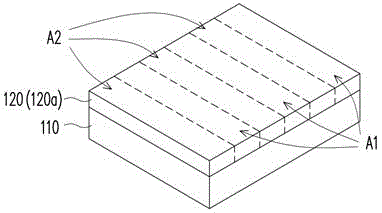

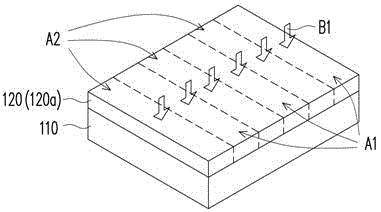

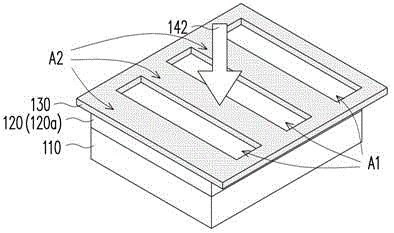

[0049] Figure 1A to Figure 1IIt is a schematic side view of the manufacturing process of the optical film according to an embodiment of the present invention.

[0050] Please refer to Figure 1A , coating the alignment liquid 120 on the first substrate 110, wherein the first substrate 110 has a first area A1 and a second area A2, and the first area A1 and the second area A2 are arranged alternately. In this embodiment, the alignment liquid 120 may be a photopolymerizable alignment material 120a, however, the present invention is not limited thereto. In addition, the method of coating the alignment liquid 120 on the first substrate 110 may be spin coating, slit coating or any other well-known method with common knowledge in this field, which will not be repeated here. detail.

[0051] Please refer to Figure 1B , and then, the alignment liquid 120 is subjected to a pre-baking B1 process. It should be noted that the temperature and time control of the pre-bake B1 process wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com