Self-radiating motor

A self-heating, motor shaft technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems that the self-heating effect of the same motor cannot be satisfied, the heat dissipation effect is poor, and the components are in a relatively harsh working environment, so as to achieve a better self-heating effect Good, meet the heat dissipation requirements, reduce the temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

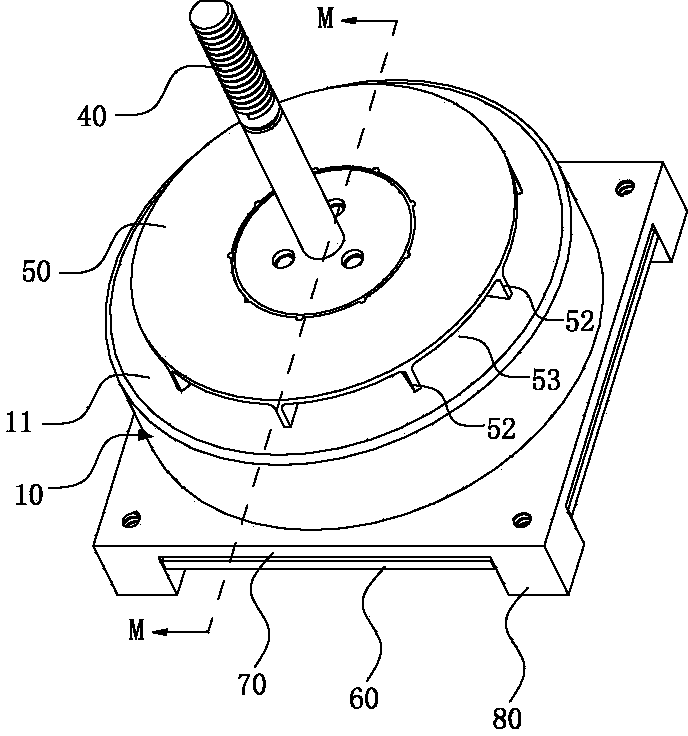

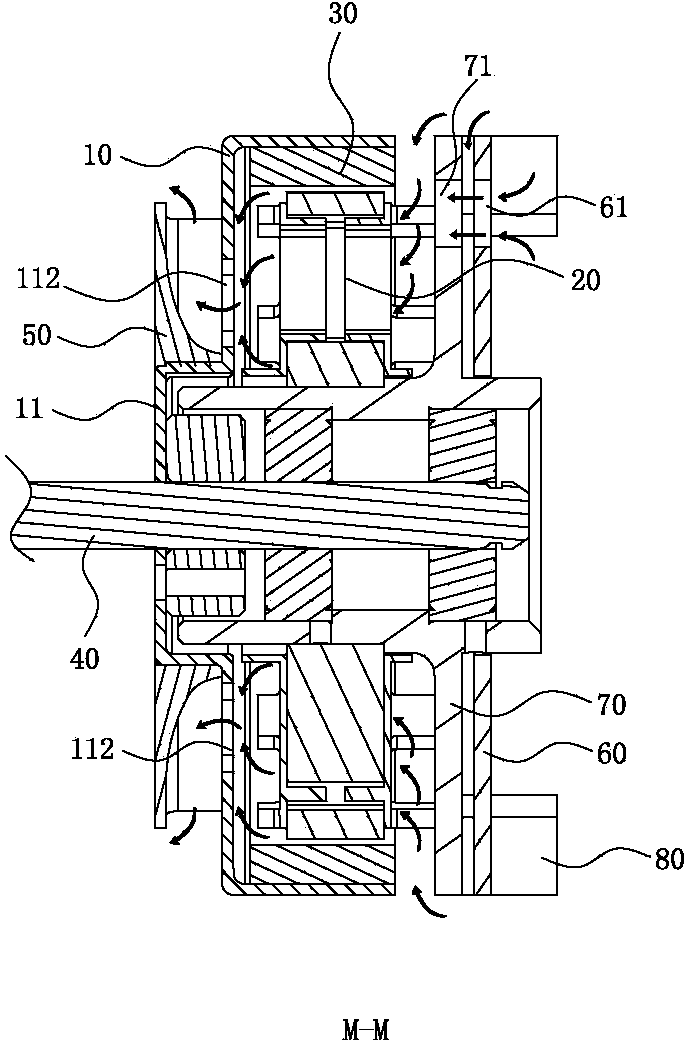

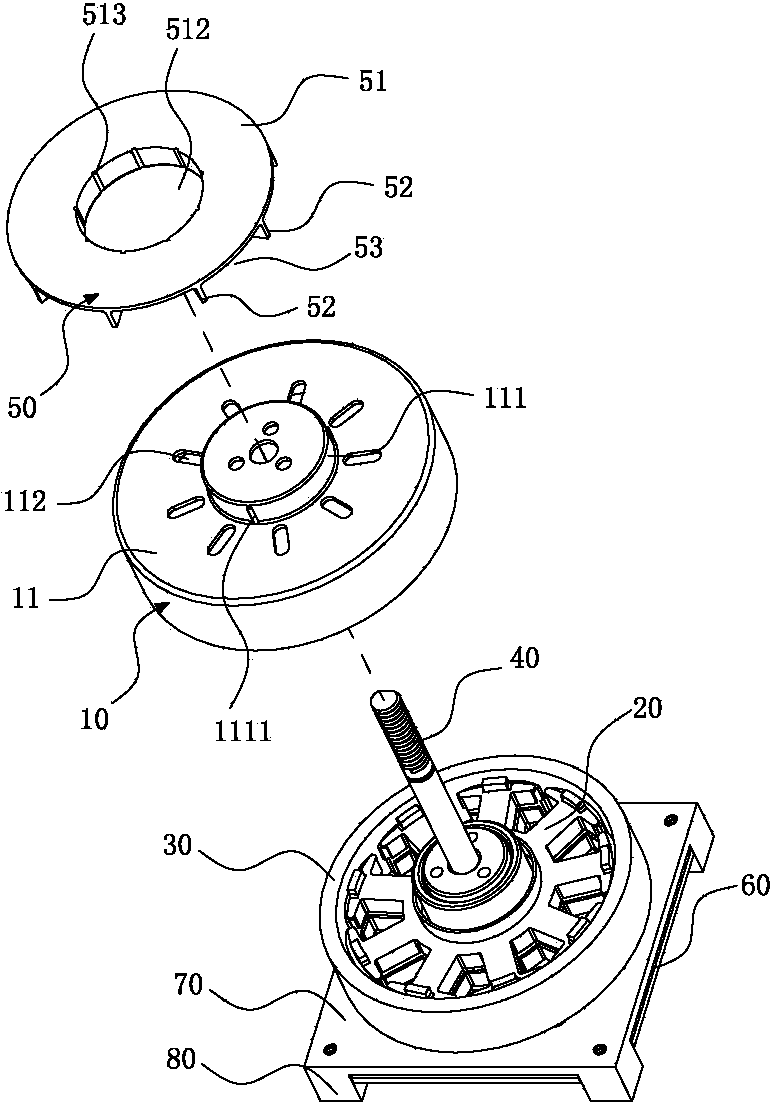

[0043] See Figure 1 to Figure 7 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a housing 10, a stator 20, a rotor 30, a motor shaft 40, a fan blade 50 and a circuit board 60. The internal structure and working principle of the motor are not the innovations of this case, so I will not repeat them here.

[0044] Wherein, the housing 10 is sleeved on the aforementioned motor shaft 40, and rotates with the motor shaft 40; the housing 10 has an end cover 11, the end cover 11 is formed with a sleeve portion 111 outward along the direction of the motor shaft 40, and A block 1111 is protrudingly provided on the outer peripheral side of the sleeve portion 111, and a third heat dissipation hole 112 is provided on the end cover 11 corresponding to the position of each guide groove 53 of the fan blade 50 described below.

[0045] The fan blade 50 is a fan blade 50 capable of drawing air from the inside of the housing 10, and is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com