Integrated high-heat-conductivity substrate LED (light-emitting diode) lamp

A technology for LED lamps and LED strips, applied in lighting and heating equipment, semiconductor devices of light-emitting components, non-polymer adhesive additives, etc. The problem of the large size of the power LED light board is to achieve the effect of good self-heating performance, high power and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

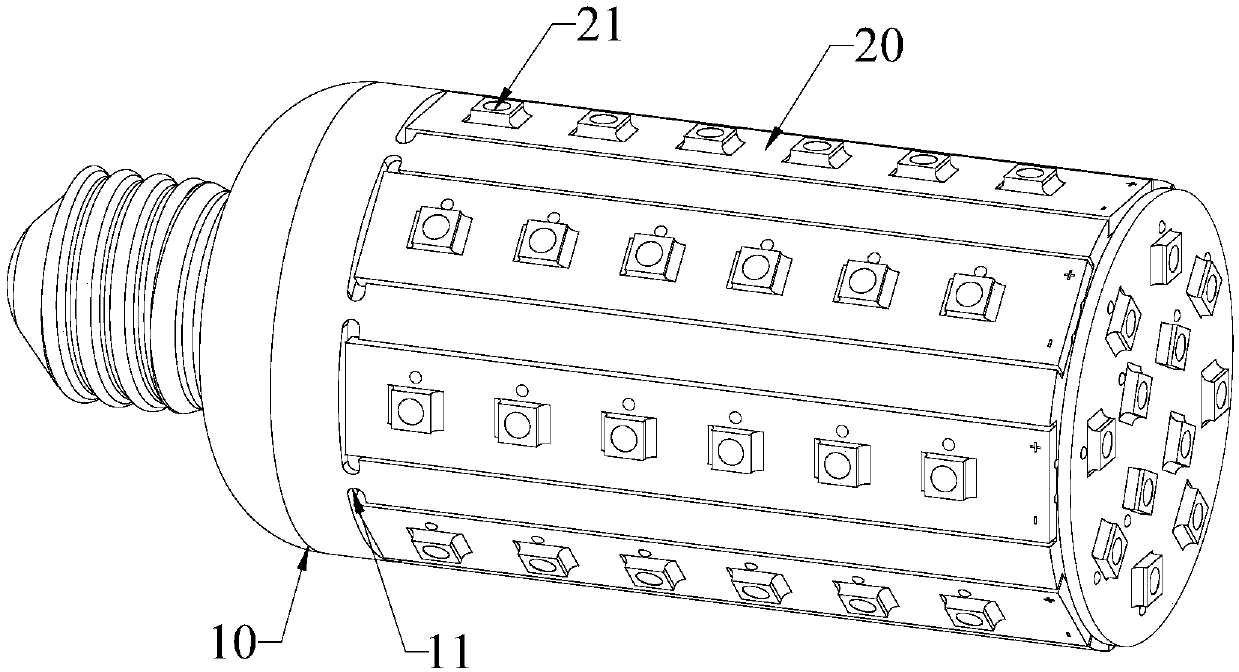

[0017] Such as figure 1 As shown, the integrated high thermal conductivity substrate LED lamp includes a thermally conductive lamp body 10 and an LED light bar 20 , and the outer wall of the thermally conductive lamp body 10 is provided with a plurality of accommodation grooves 11 for accommodating the LED light bar 20 . The LED light bar 20 includes a high thermal conductivity aluminum substrate and LED lamp beads 21 arranged in an array on the front of the high thermal conductivity aluminum substrate. The high thermal conductivity aluminum substrate includes a circuit layer, a high thermal conductivity insulating layer and a copper plate layer. The lamp bead 21 is electrically connected, and the insulating layer with high thermal conductivity is fixed between the circuit layer and the copper plate layer; the copper plate layer and the receiving groove 11 are packaged with high thermal conductivity LED encapsulation glue.

[0018] Mix and stir 100Kg epoxy resin, 3.5Kg tertiar...

Embodiment 2

[0021] Mix and stir 110Kg epoxy resin, 4Kg tertiary amine curing agent, 1.5Kg imidazole accelerator, 3Kg silane coupling agent, 106Kg high thermal conductivity filler and 55Kg solvent to make glue, which is heat-cured to make high Thermal insulating layer. Wherein, the high thermal conductivity filler is aluminum nitride powder with a particle size less than or equal to 0.6 μm. The thermal conductivity of the high thermal conductivity insulating layer is 2.12W / (mk).

[0022] Mix 100Kg of silicone potting glue, 11Kg of polydimethylsiloxane, and 36Kg of hexagonal boron nitride powder with a particle size less than or equal to 0.6μm to form a primary rubber, and add it to the primary rubber under moisture-proof conditions. Mix 0.56Kg of methyltrimethoxysilane and 0.21Kg of 3-aminopropyltrimethoxysilane evenly to form a high thermal conductivity LED encapsulant. The thermal conductivity of the high thermal conductivity LED packaging adhesive is 1.39W / (m·k). The high thermal con...

Embodiment 3

[0024] Mix and stir 120Kg epoxy resin, 4.3Kg tertiary amine curing agent, 1.6Kg imidazole accelerator, 3.6Kg silane coupling agent, 110Kg high thermal conductivity filler and 60Kg solvent to make a glue, which is made by heat curing. Into a high thermal conductivity insulating layer. Wherein, the high thermal conductivity filler is aluminum nitride powder with a particle size less than or equal to 0.6 μm. The thermal conductivity of the high thermal conductivity insulating layer is 2.08W / (mk).

[0025] Mix 100Kg of silicone potting glue, 12Kg of polydimethylsiloxane, and 40Kg of hexagonal boron nitride powder with a particle size less than or equal to 0.6μm to form a primary rubber, and add it to the primary rubber under moisture-proof conditions. Mix 0.6Kg of methyltrimethoxysilane and 0.22Kg of 3-aminopropyltrimethoxysilane evenly to form a high thermal conductivity LED encapsulant. The thermal conductivity of the high thermal conductivity LED packaging adhesive is 1.35W / (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com