Fast-mounted water film deduster

A water-film dust collector and quick-loading technology, applied in chemical instruments and methods, dispersed particle separation, use of liquid separators, etc., can solve the problems of uniform flow of overflow water, uneven water film, and difficulty in cleaning dust, etc. The overflow water film is uniform, the dust removal effect is good, and the production is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

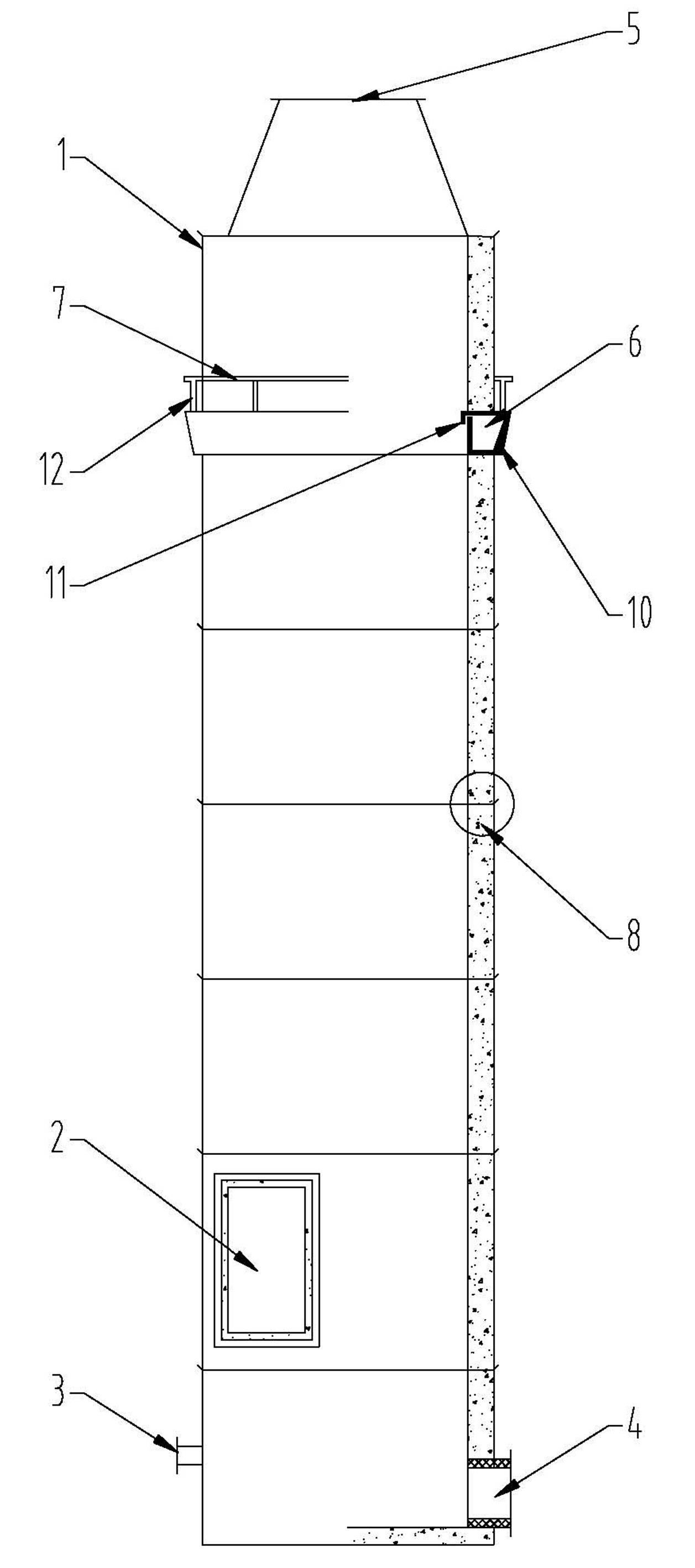

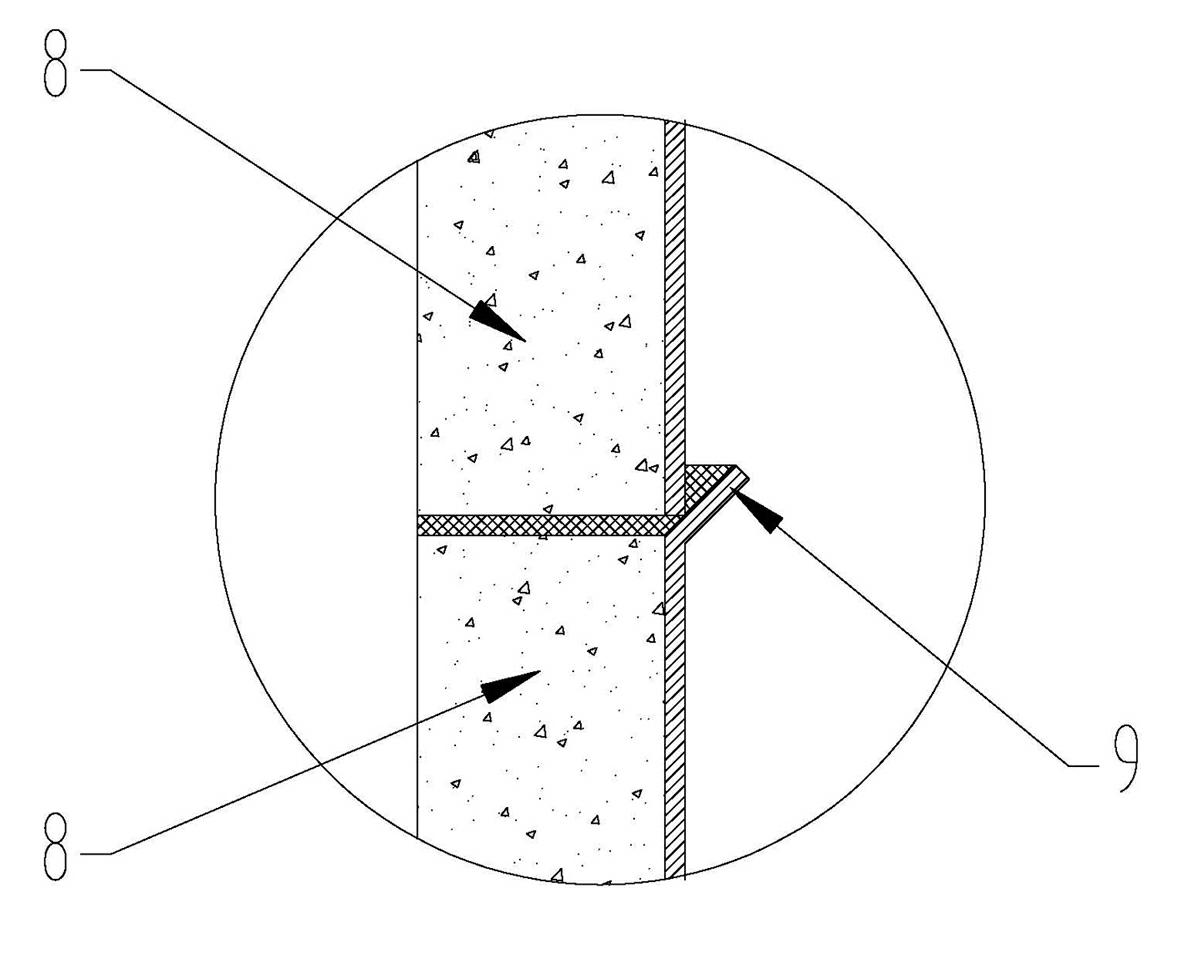

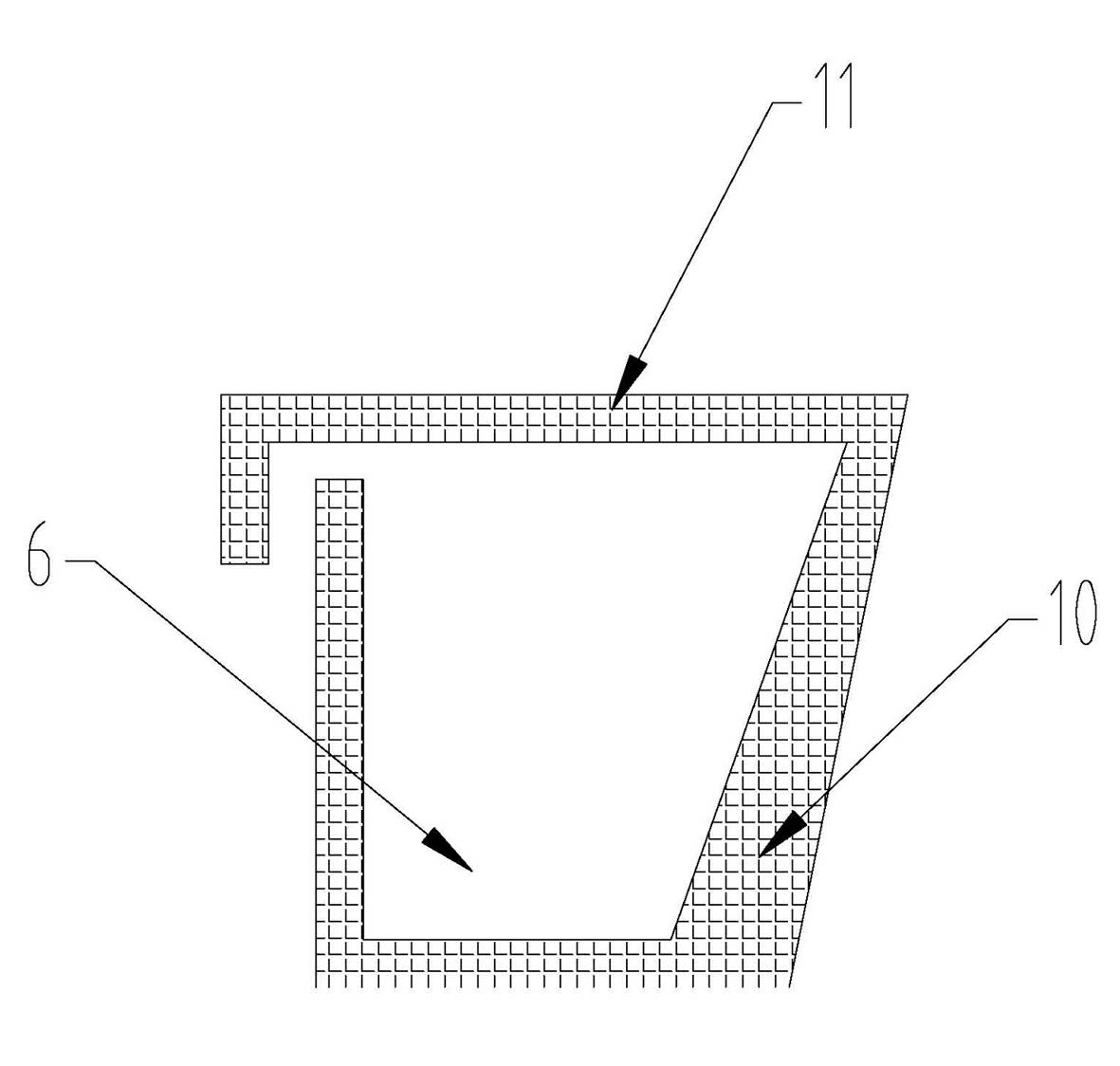

[0024] Such as Figure 1-4 Shown: a quick-installed water film dust collector, including a cylinder 1, the cylinder 1 is composed of a plurality of sub-cylinders 8 with a length of 1-2m, and a bell mouth with an upward opening is arranged on the upper end of the sub-cylinders 8 9. Between multiple sub-cylinders 8, the lower end of the upper sub-cylinder 8 is embedded in the bell mouth 9 at the upper end of the sub-cylinder 8 on the lower side to assemble the cylinder 1, and the connection of the sub-cylinders 8 The bell mouth 9 is filled and sealed with acid-resistant cement; the sub-cylinders 8 are respectively composed of granite slab layers, acid-resistant cement concrete layers and steel plate layers from the inside to the outside. A flue gas inlet 2 is provided on the lower side wall of the cylinder body 1, and an overflow port 3 and a cleaning ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap