Control cabinet for numerical-control synchronous tensioning system for jacks

A system control box and synchronous tensioning technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of low control precision and asynchronous control of the tensioning system, so as to ensure the quality of tensioning, reduce maintenance and operating costs, The effect of guaranteeing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

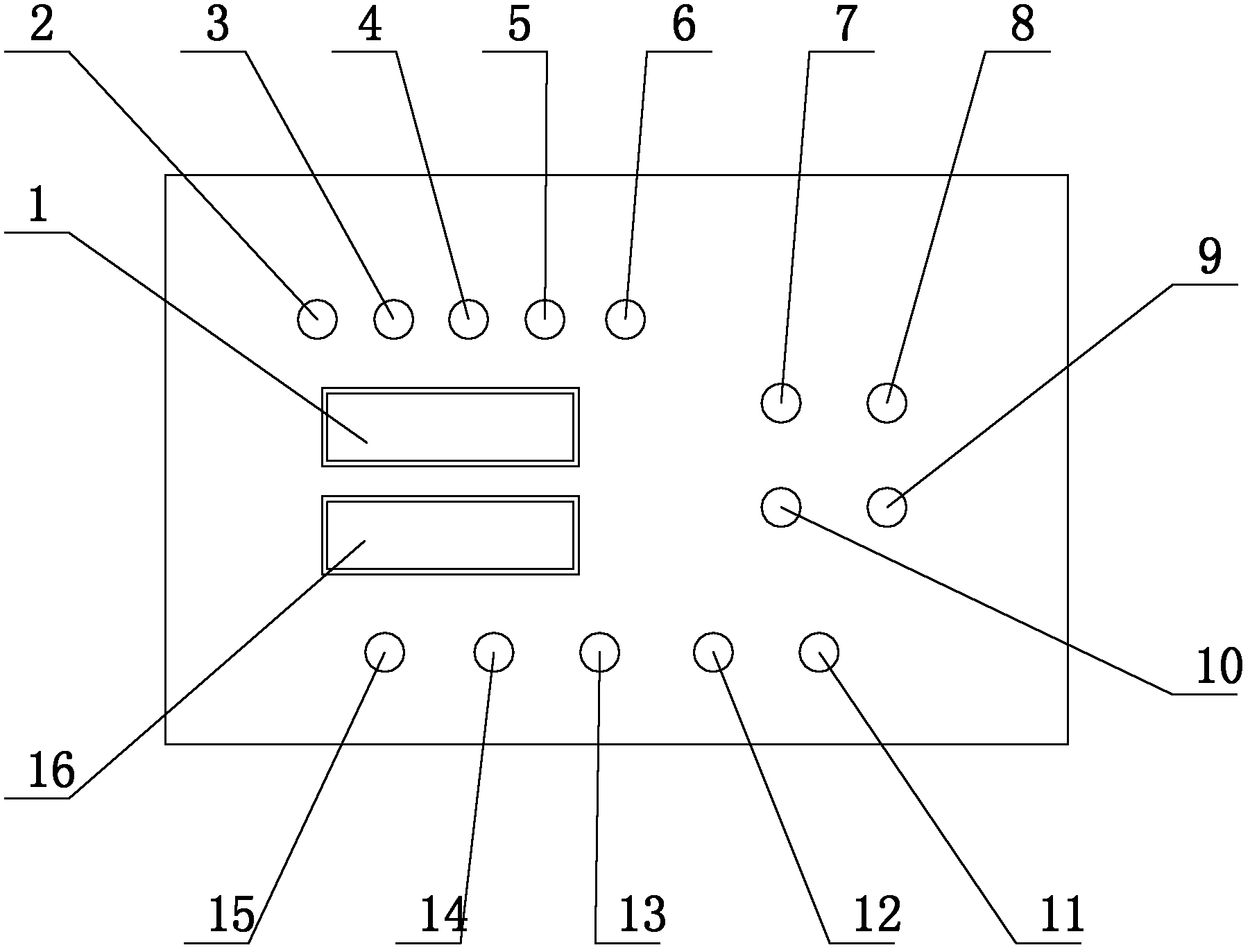

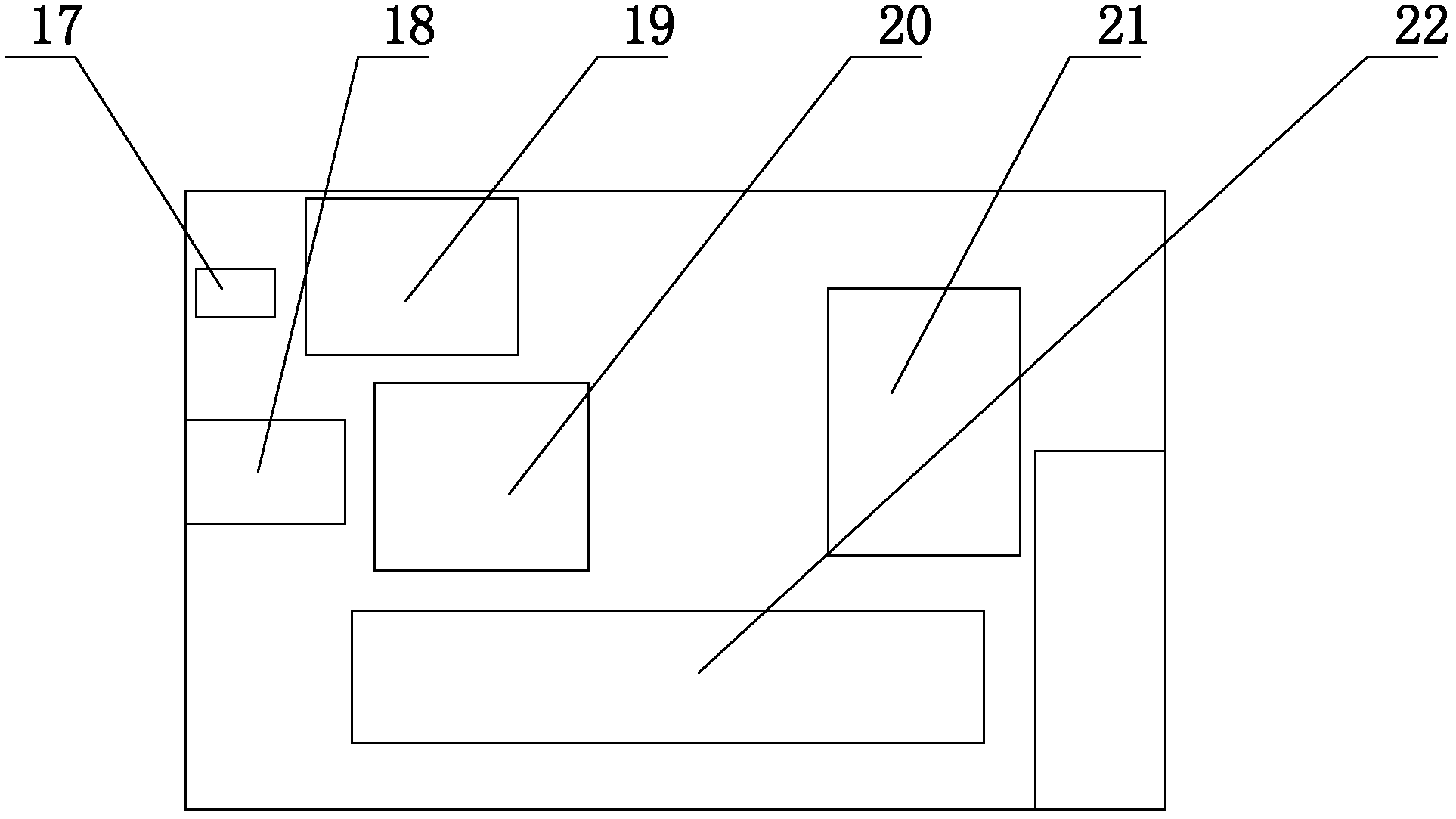

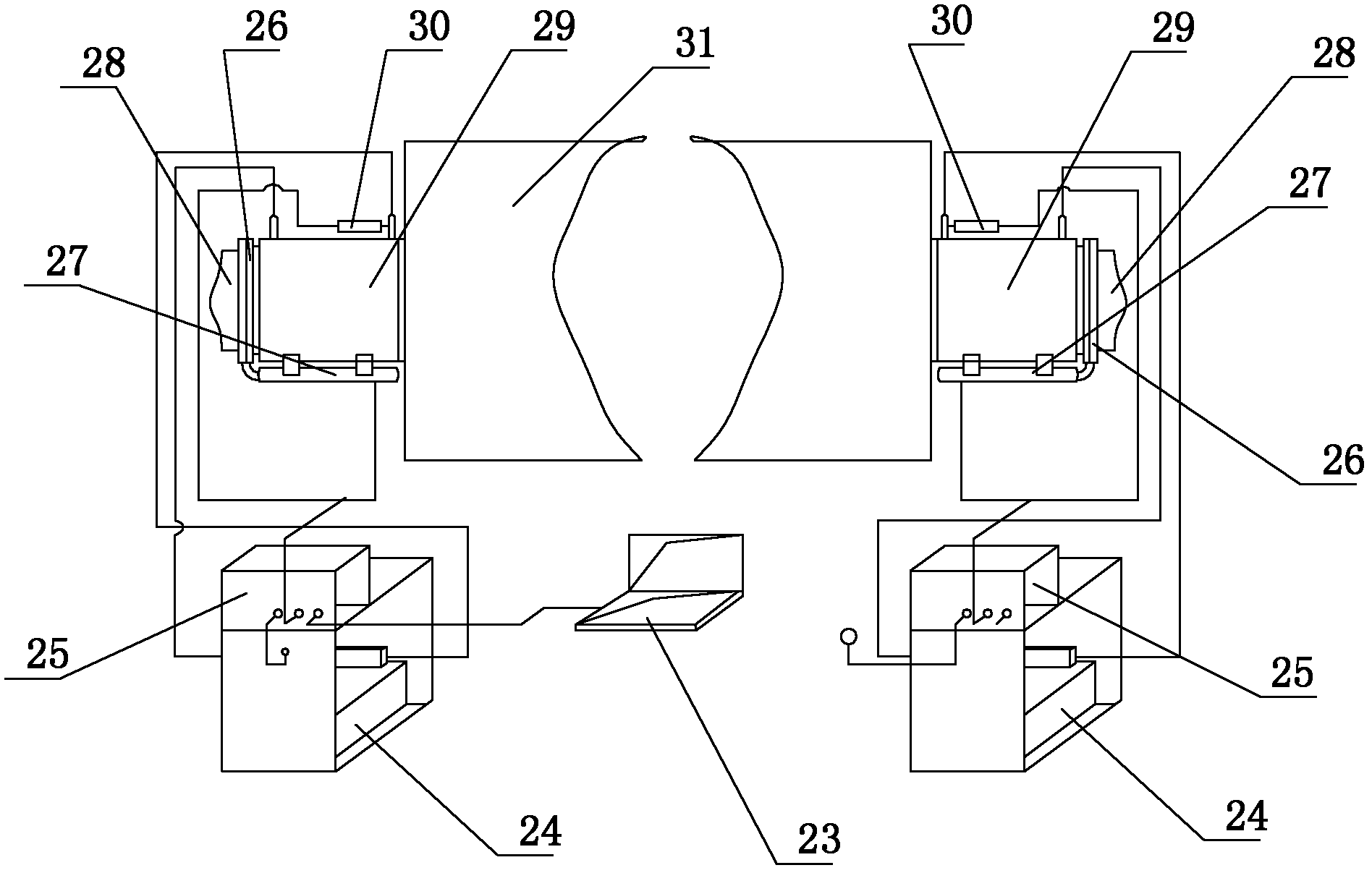

[0028] Such as figure 1 , figure 2 As shown, a control box of a jack numerical control synchronous tensioning system includes a box body, and a power module 19 , a control module 20 , a display module 21 and a communication module 22 are arranged in the box body. All modules are installed in the box.

[0029] There is a transformer 17 inside the box, and the power supply module 19 is connected to the power supply line through the transformer 17. Considering that the power supply in actual engineering construction is 380V, the voltage is converted to 220V after the contactor and transformer to supply power to the entire jack CNC synchronous tensioning system. , and then convert the 220V voltage to 24V voltage through the transformer, which is used as the working power supply of each module in the control box. The power supply module is connected to the control module, and the control module 20 is connected to the display module 21 and the communication module 22 respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com