Cotton wool with gauze surface layer and preparation method of cotton wool

A cotton batting and surface layer technology is applied in the field of gauze surface batting and its preparation, which can solve the problems that the cotton batting cannot adhere well to the human body, the density of the gauze surface layer is thin, and the use of the cotton batting is affected, so as to reduce the material cost and protect the Respiratory tract, health benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

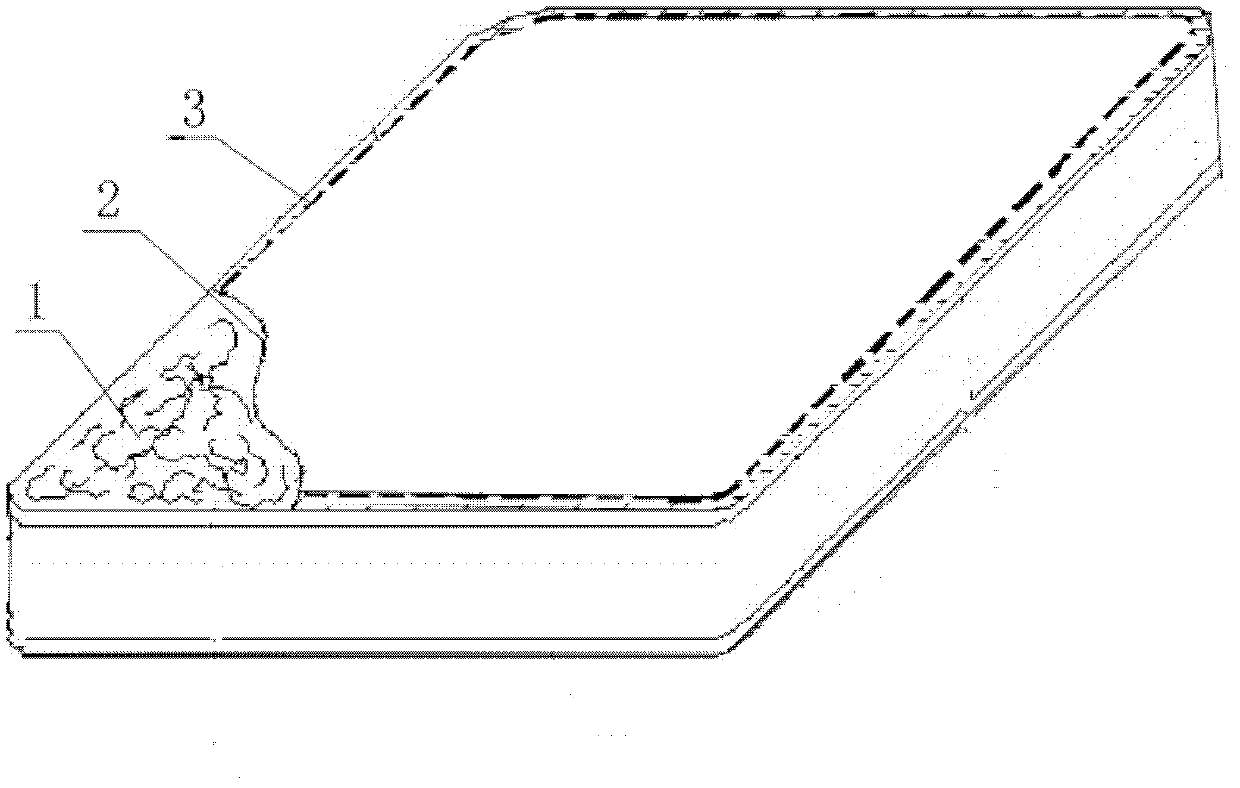

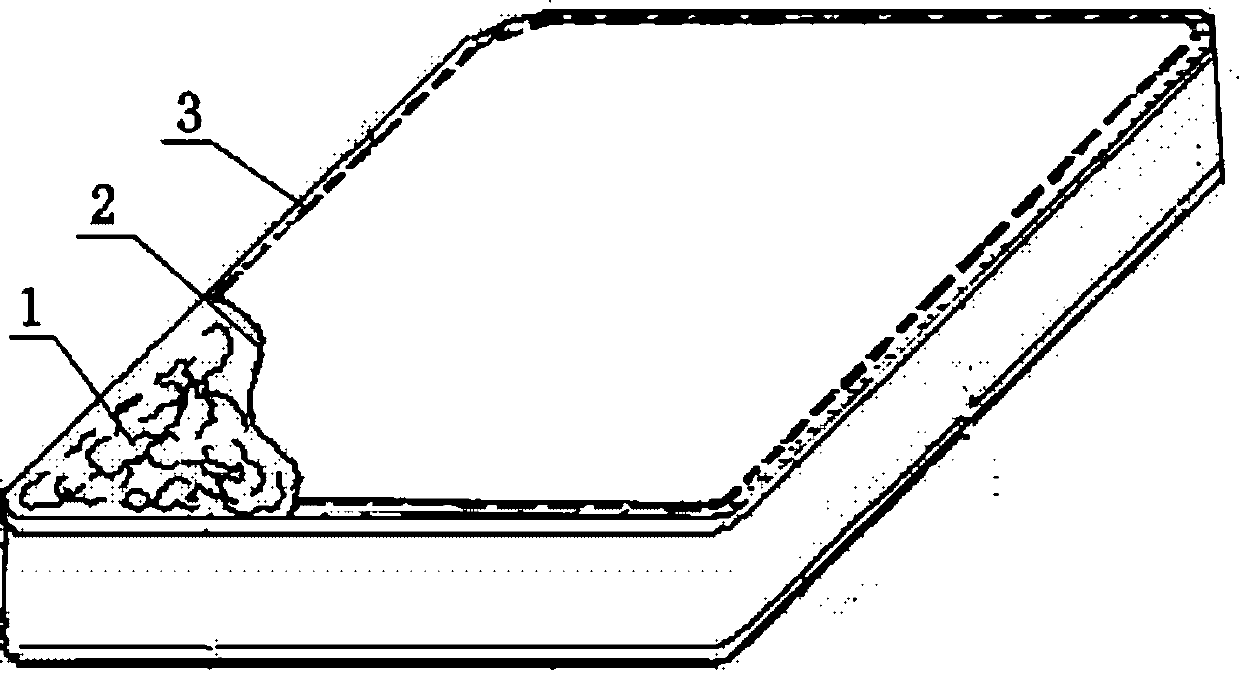

[0014] Referring to accompanying drawing, a kind of preparation method of gauze surface layer cotton wool is characterized in that described gauze surface layer cotton wool quilt core is to be finished by following process steps:

[0015] A. The cotton on the surface of the gauze is that the surface of the gauze 2 is fully covered on the outer surface of the cotton wadding 1 and is connected to the cotton wadding 1 by ironing to form an integral structure. On the outer surface, the gauze density is about 20*20--50*45;

[0016] B, adopt grinding disc machine to iron and grind the cotton-wool body 1 of covering gauze surface layer 2, make its gauze surface layer 2 and cotton-wool body 1 stick together as a whole, and its disc-grinding machine motor is a 220V three-phase AC motor, and power is 1.4-2.2 kilowatts; The ironing temperature is 30-60 degrees Celsius; the pressure control is 18000KPa-26000KPa / square meter; the ironing time is 10-30 minutes;

[0017] C. Use a side cutte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com