Spiral-flow type elutriation and separation device for dredging sludge and sludge elutriation pretreatment method of device

A technology for communicating sludge and separating devices, which is applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc. To achieve the effect of reducing water consumption, shortening elutriation time, and improving elutriation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

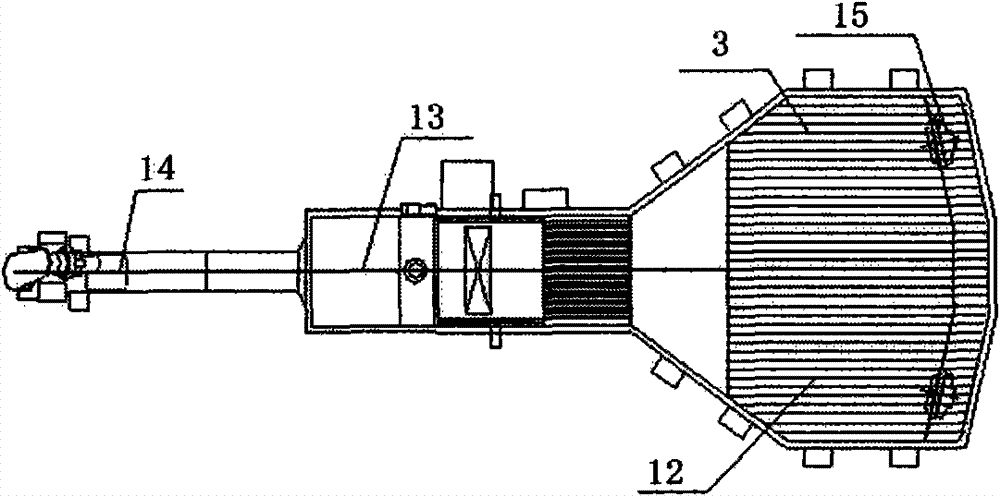

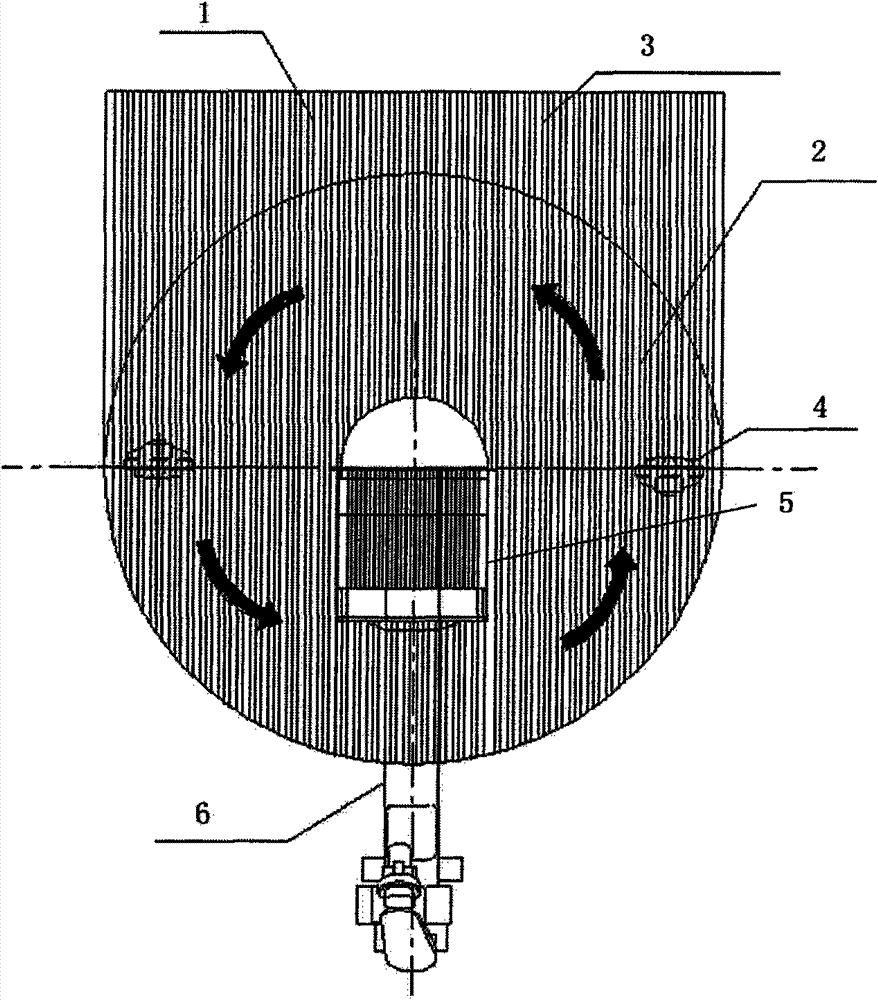

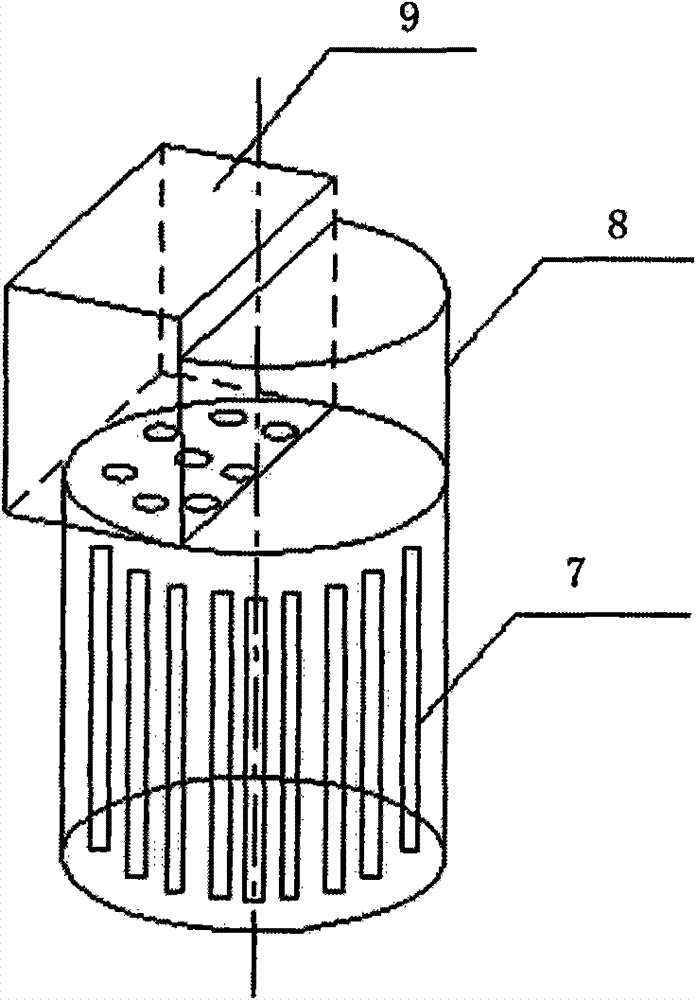

[0012] As shown in the figure, a swirling ditch sludge elutriation and separation device includes a sludge receiving and mixing tank 2, which is characterized in that the sludge receiving and mixing tank 2 is equipped with a steel platform grid 3, and a steel platform grid 3 is provided with a discharge chute 1, the grid spacing of the steel platform grille 3 is 5cm to 10cm, and the center of the sludge receiving mixing tank 2 is provided with a water collection cylinder, which includes a sewage collection cylinder 7, and the top of the sewage collection cylinder is set There is a scum collecting tank 8, the bottom of the sludge receiving and mixing tank 2 is a conical tank with a taper of 2:1 to 3:1, the side of the sludge receiving and mixing tank 2 is provided with a water inlet pipe 10, and the bottom of the sewage collecting tank 7 is provided with an outlet Water pipe 11, the bottom of the sludge receiving mixing tank is sealed, and the outlet pipe and the sludge receivin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com