A kind of fluidized bed residual oil hydrogenation method

A technology of ebullating bed and bed residue, which is applied in the petroleum industry, refining hydrocarbon oil, etc. It can solve the problems of complicated processing methods and high equipment investment, and achieve the effects of facilitating internal circulation, improving utilization rate, and reducing residual carbon value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

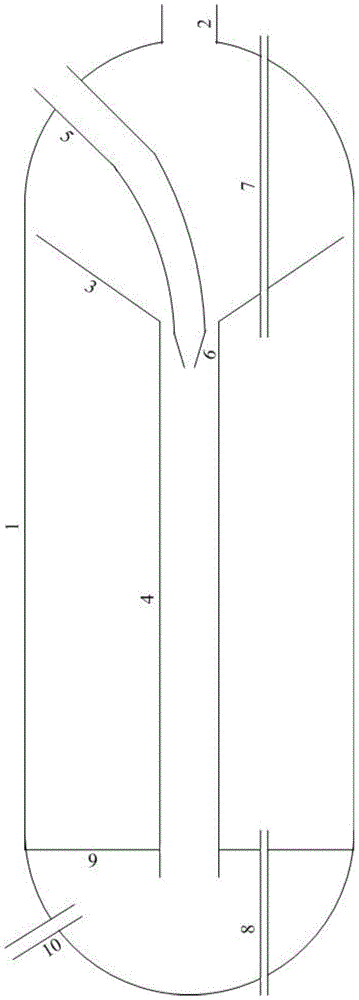

[0037] The raw material residue F1 is an atmospheric residue with high Ca content, and its properties are shown in Table 1. Using a structure such as figure 1 The ebullated bed reactor shown carries out the hydrogenation reaction. Wherein, a diameter-reducing part 6 is provided at the outlet of the high-pressure oil guide pipe 5, and the ratio of the maximum inner diameter to the minimum inner diameter of the diameter-reducing part 6 is 7:1. The largest inner diameter part of the reduced diameter part 6 is located in the vertical oil guide pipe 4, and the ratio of the radial distance between the corresponding outer wall and the inner wall of the vertical oil guide pipe 4 to the inner diameter of the vertical oil guide pipe 4 is 0.2:1. The ratio of the axial distance between the outlet end of the high pressure oil guide pipe 5 and the inlet end of the vertical oil guide pipe 4 to the length of the vertical oil guide pipe 4 is 1:10.

[0038] The ebullating bed hydrogenation ca...

Embodiment 2

[0049] The raw material residue F2 is an atmospheric residue with high Ni and V content, and its properties are shown in Table 4. Using a structure such as figure 1 The ebullated bed reactor shown carries out the hydrogenation reaction. The catalyst is the RDM-33 produced by Sinopec Catalyst Changling Branch developed by the Research Institute of Petrochemical Sciences. The catalyst is made into a cylindrical shape with a diameter of 0.7mm to adapt to the ebullated bed hydrogenation reactor catalyst. 1.5 liters of RDM-33 catalyst was loaded into the ebullating bed hydrogenation reactor, and the height of the catalyst material level was 50% of the height of the ebullating bed reactor.

[0050] Through the high-pressure oil guide pipe 5, feed the residual oil raw material and the hydrogenated vacuum residual oil circulated by the fractionation system into the fluidized bed hydrogenation reactor. The flow rate of the residual oil raw material introduced is 400g / h, and the hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com