Ecological water-retaining agent used for restoring saline lands, and preparation method thereof

A water-retaining agent, saline-alkali soil technology, applied in chemical instruments and methods, applications, organic fertilizers, etc., can solve the problems of low gel strength, poor salt tolerance, short service life, etc. The effect of low agent cost and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

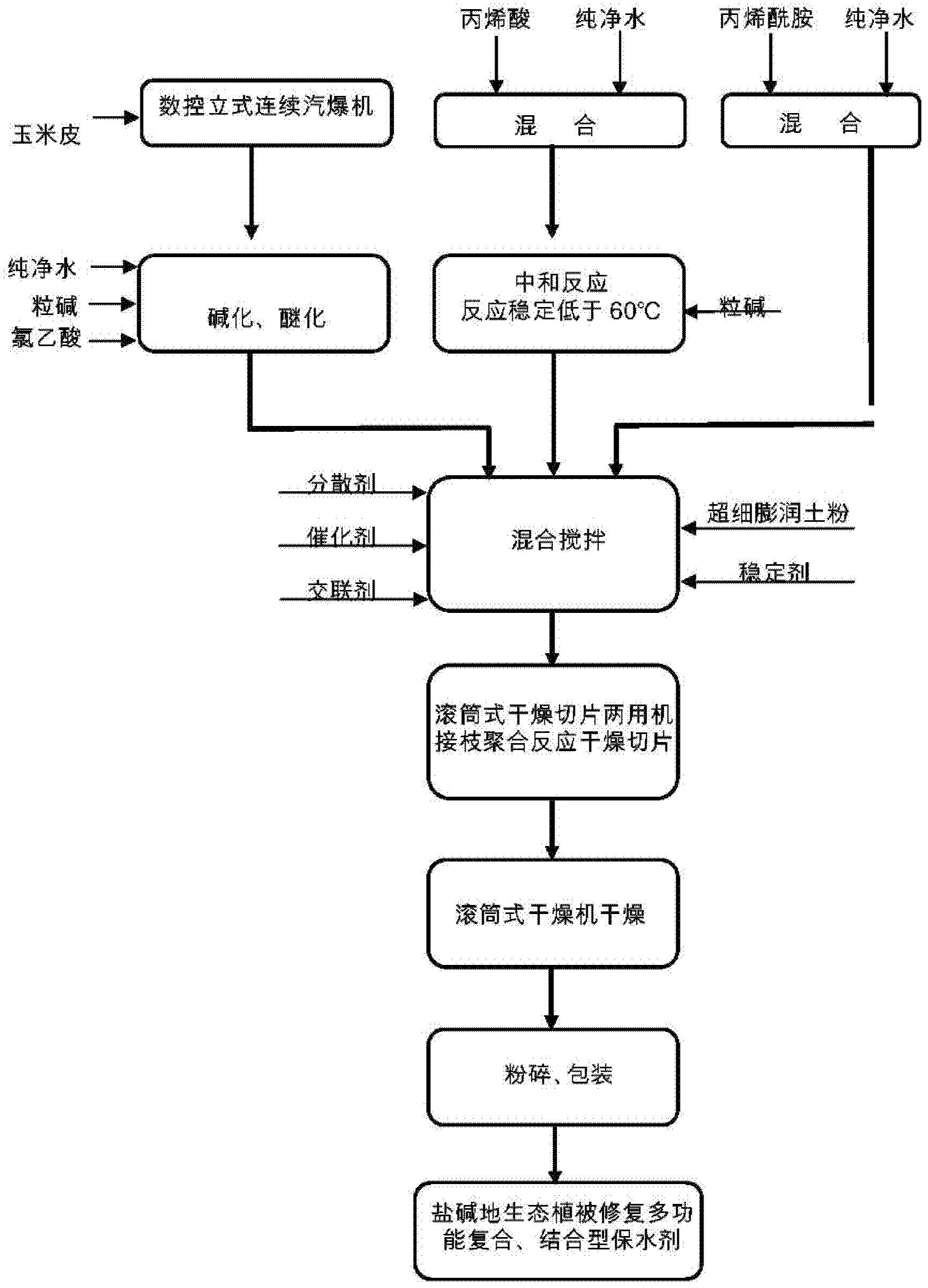

Method used

Image

Examples

Embodiment 1

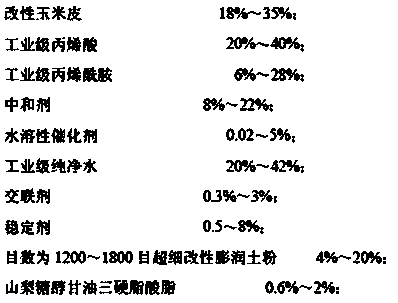

[0040] Embodiment 1: A water-retaining agent for restoring the ecology of saline-alkali land, the water-retaining agent is composed of the following parts by weight:

[0041]

[0042]

[0043] The water-soluble catalyst is potassium persulfate or hydrogen peroxide or ammonium persulfate. The crosslinking agent is glycerol or epichlorohydrin or N,N-methylenebisacrylamide. The stabilizer is polyethylene glycol or polypropylene oxide or polyoxyethylene nonphenyl ether. The molecular formula of the technical grade acrylic acid is CH 2 =CHCOOH, the content of acrylic acid is greater than 99%. The molecular formula of industrial grade acrylamide is: CH 2 =CHCONH 2 , the content of acrylamide is greater than 98%. The neutralizing agent refers to the industrial ionic membrane method granular alkali with a content greater than 99%. The industrial-grade purified water has no calcium and magnesium ions.

[0044] The preparation steps of described modified corn bran are:

[...

Embodiment 2-10

[0049] Embodiment 2-10: the same as embodiment 1, the difference is that the water-retaining agent is composed of substances according to the parts by weight in the following table:

[0050]

Embodiment 11

[0051] Embodiment 11: the same as embodiment 1, the difference is:

[0052] The preparation steps of described modified corn bran are:

[0053] 1) Firstly, corn husks are steam-exploded using a continuous steam explosion machine, and the steam explosion conditions are as follows: the density of the corn husks is 140Kg / m3, the holding time is 60S, and the pressure is 0.8-0.9MPa.

[0054] 2) Add the corn bran after step 1) in the reaction kettle, add water and adjust to a slurry with a corn bran content of 15%, then slowly add 25% sodium hydroxide solution for alkalization, at this time, the corn bran and The mass ratio of sodium hydroxide is 1:0.6;

[0055] 3) Stir at 35-45°C for 20 minutes and then add chloroacetic acid for etherification. At this time, the mass ratio of corn bran to chloroacetic acid is 1:0.6;

[0056] 4) Raise the temperature to 60° C. while maintaining constant temperature and stirring for 60 minutes, wash with ethanol, dry and pulverize after washing to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com