Method of enabling fiber structures to be continuously durable and hydrophobic

A fiber structure, hydrophobic technology, applied in fiber processing, liquid repellent fibers, textiles and papermaking, etc., can solve the problems of different structures and effects, and achieve the effect of good sustainable and durable waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

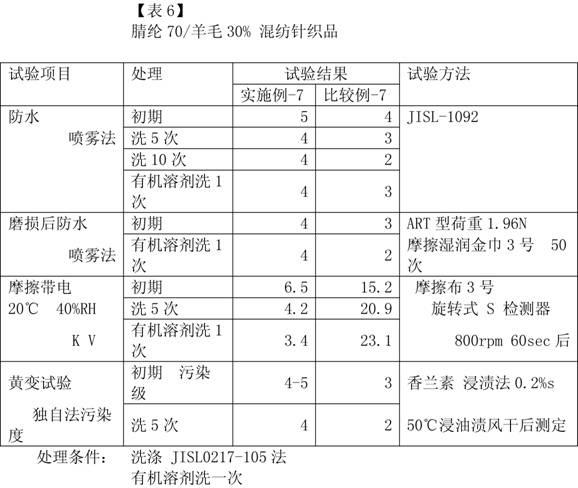

[0079] Comparative Example 8

[0080] Using the same cloth as in Example 8, the dyed and dried cloth does not need to be treated with the C fiber modifier. Take Asahi GUARD E-082 treated with fluorine-based waterproofing agent at the same 60g / L, and put other additives under the same conditions for waterproofing. However, due to the results of the prior confirmation experiment, the texture of the material has a rough feeling and does not meet the characteristics of the material, so the bath needs to be adjusted, and amino silicone oil (manufactured by Nikka Chemical Co., Ltd.) 3g / L should be added to the padding bath. . The extrusion rate remains unchanged, and the processing is completed under the same process. The results are shown in Table 7.

[0081]

[0082]

[0083]

[0084]

[0085]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com