A modular energy conversion device and its working method and application

An energy conversion device and modular technology, which is applied in pump devices, safety devices, ocean energy power generation and other directions, can solve the problems of difficulty in promoting the commercialization, industrialization, complex structure and difficult maintenance of wave energy power generation devices, and achieves a solution to the problem of marine energy generation. The effect of biofouling, facilitating commercialization, and rapid assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

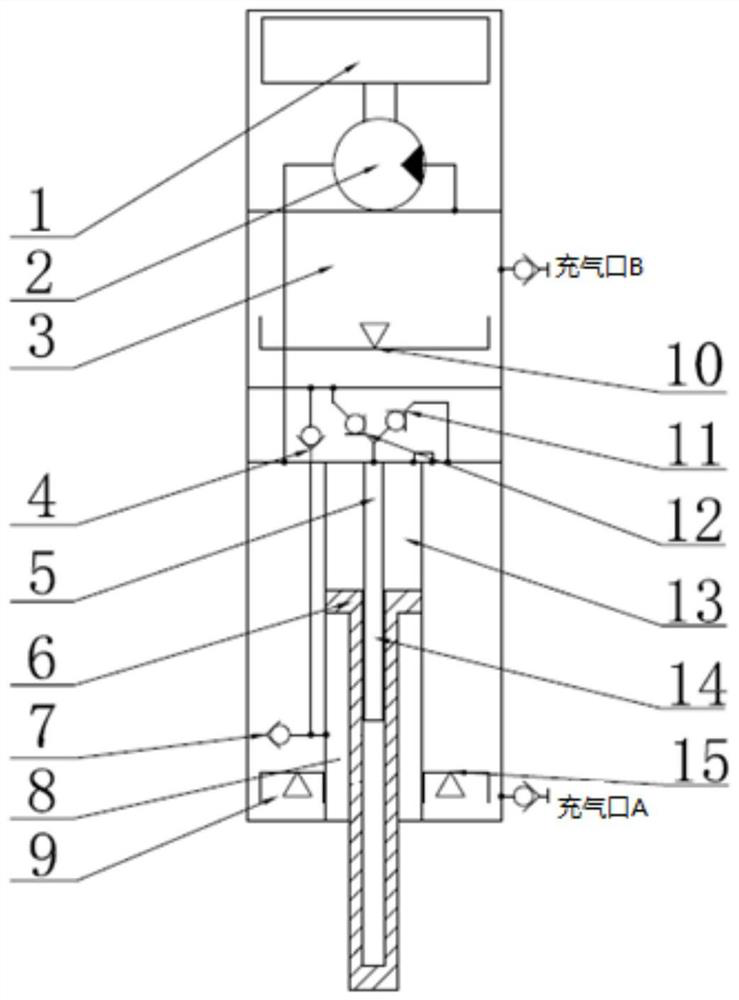

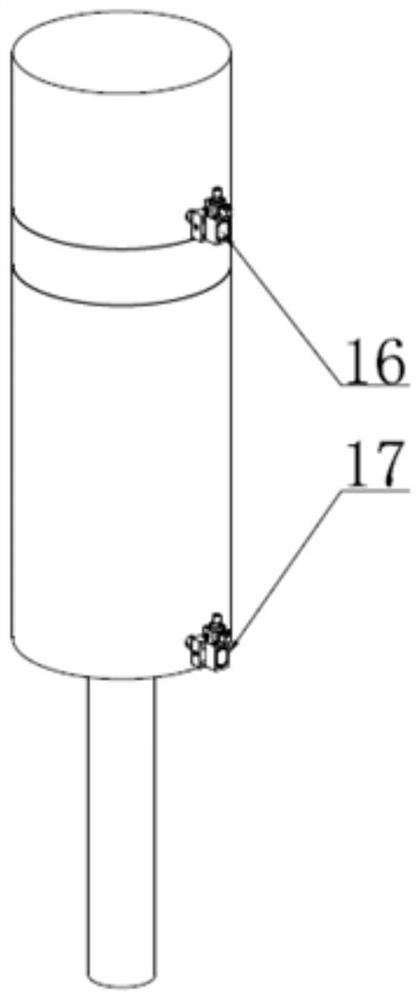

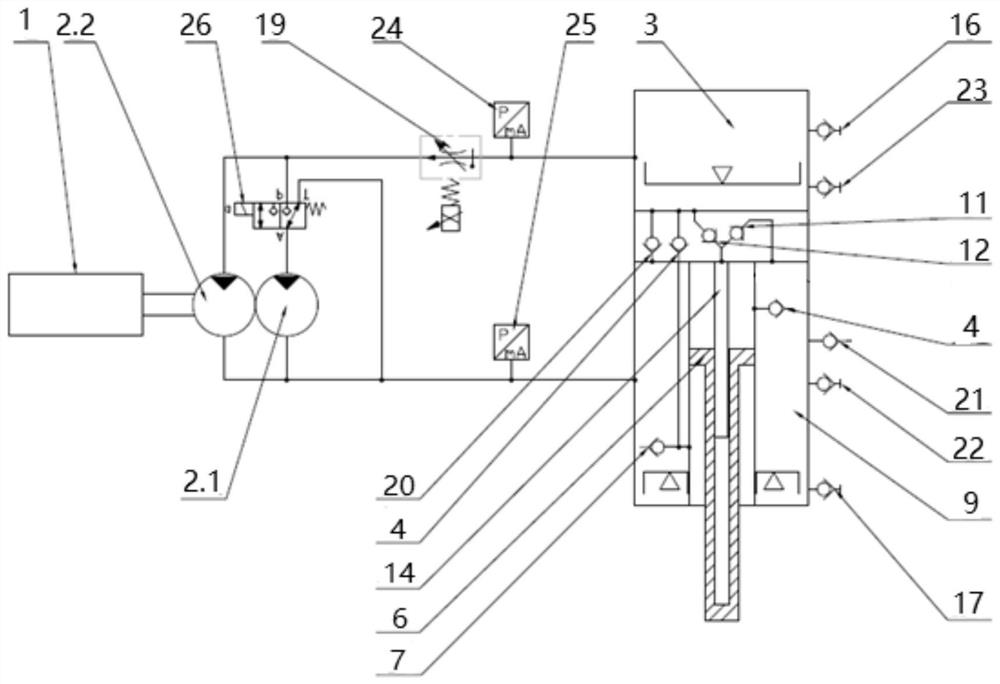

[0057] A modular energy conversion device such as Figure 1-9 As shown, it includes an actuator module, a cartridge valve module, a high-pressure accumulator module, a power generation module and a buoy module 18. The buoy module 18 is used to float on the water surface / sea surface and is in direct contact with waves. The actuator module includes a first-stage Hollow piston rod 6, secondary hollow piston rod 14 and low-pressure accumulator 9, the shape of low-pressure accumulator 9 is a hollow ring column, its outer circular wall is the housing of the actuator module, and the inner circular wall is used to set a The first cavity 8 of the actuator is formed between the low-pressure accumulator 9 and the first-stage hollow piston rod 6, and the second-stage hollow piston rod 14 is slid in the hollow structure of the first-stage hollow piston rod 6, that is, the first-stage The hollow piston rod is also used as the piston cylinder of the secondary hollow piston rod. The secondary...

Embodiment 2

[0064] A modularized energy conversion device, as described in Embodiment 1, the difference is that the connection between the housing of the power generation module, the housing of the high-pressure accumulator, the housing of the cartridge valve and the housing of the actuator module is through 90 The mortise and tenon structure can be connected, and then quick assembly can be realized; the mortise and tenon structure of the present invention can be carried out with reference to the prior art, as long as it can realize quick assembly;

[0065] An insertion hole is arranged in the cartridge valve housing, and the one-way valve A 4 , the one-way valve B 7 and the one-way valve C12 are inserted and fixed in the insertion holes.

Embodiment 3

[0067] A modular energy conversion device, as described in Embodiment 1, the difference is that the gas charging port B on the upper part of the movable piston 10 of the high-pressure accumulator is filled with nitrogen at a pressure above 10Mpa, and the movable piston 15 of the low-pressure accumulator is filled with nitrogen. The pressure of nitrogen gas in the upper gas charging port A is 0.5Mpa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com