Cooling method used for segmented geometric adjustment of guide vanes of gas turbine

A gas turbine and cooling method technology, which is applied in the cooling of turbine/propulsion device, engine cooling, engine components, etc., can solve the problems of reducing the application difficulty of the segmented geometric adjustment method of guide vanes, and achieve the effect of preventing jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

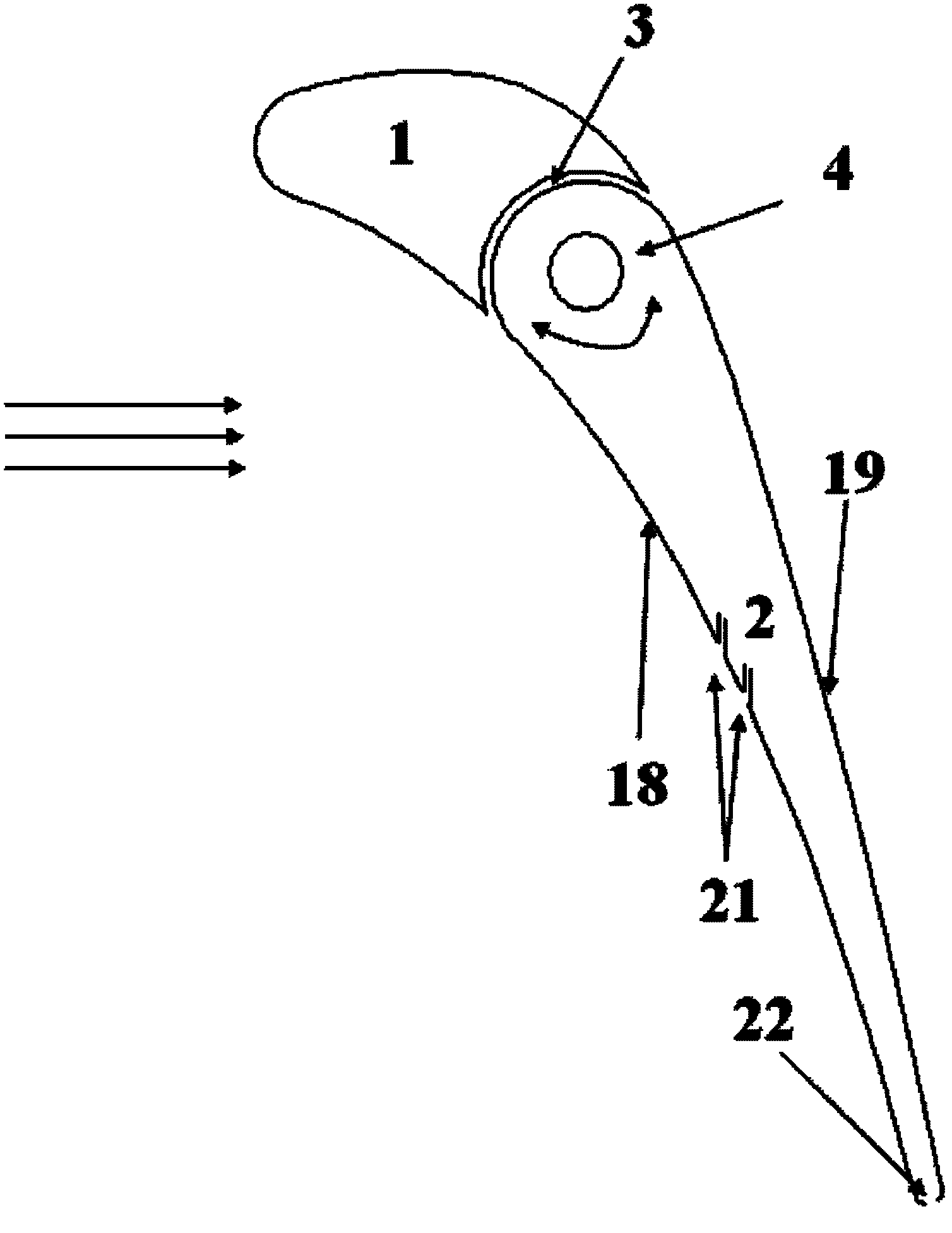

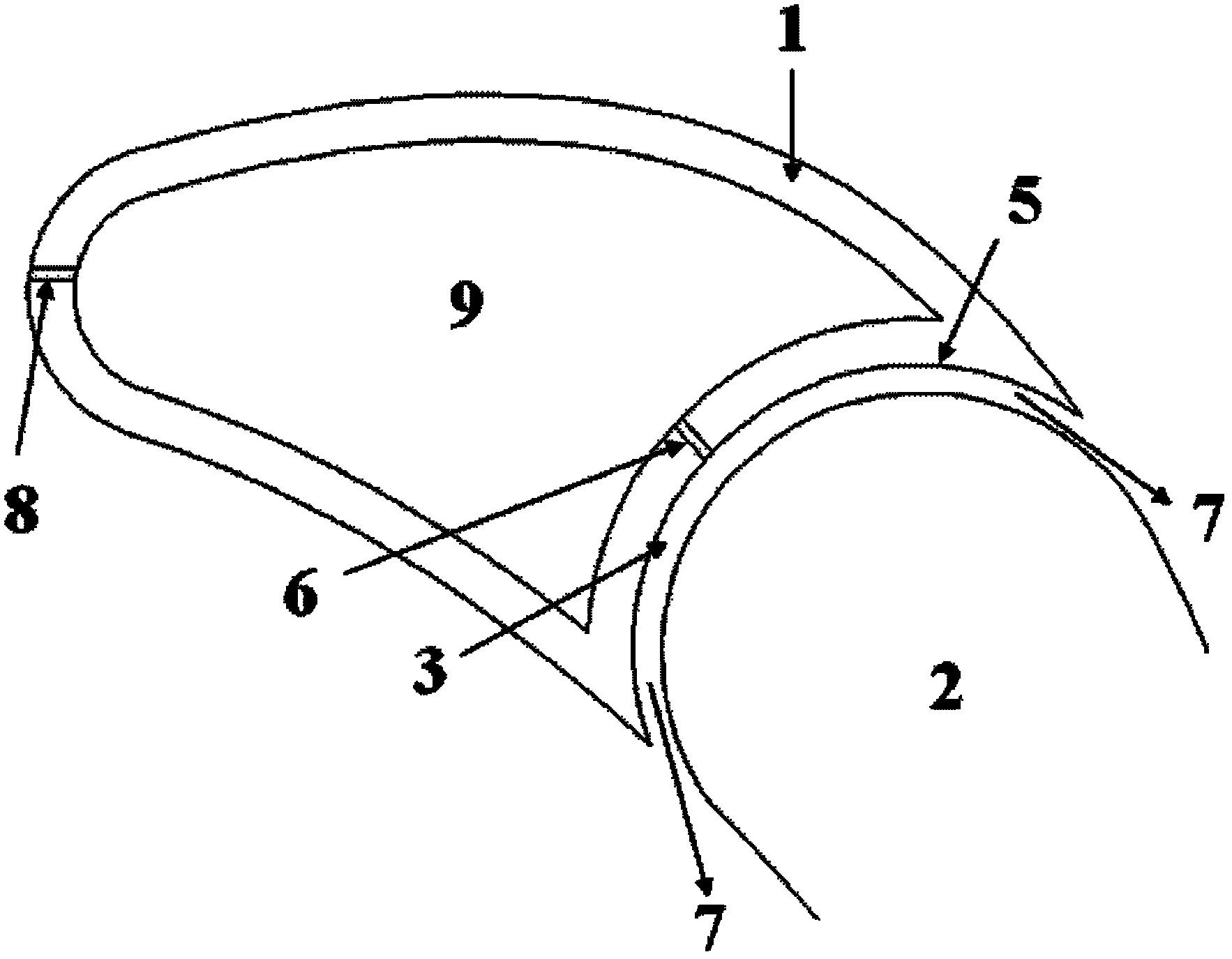

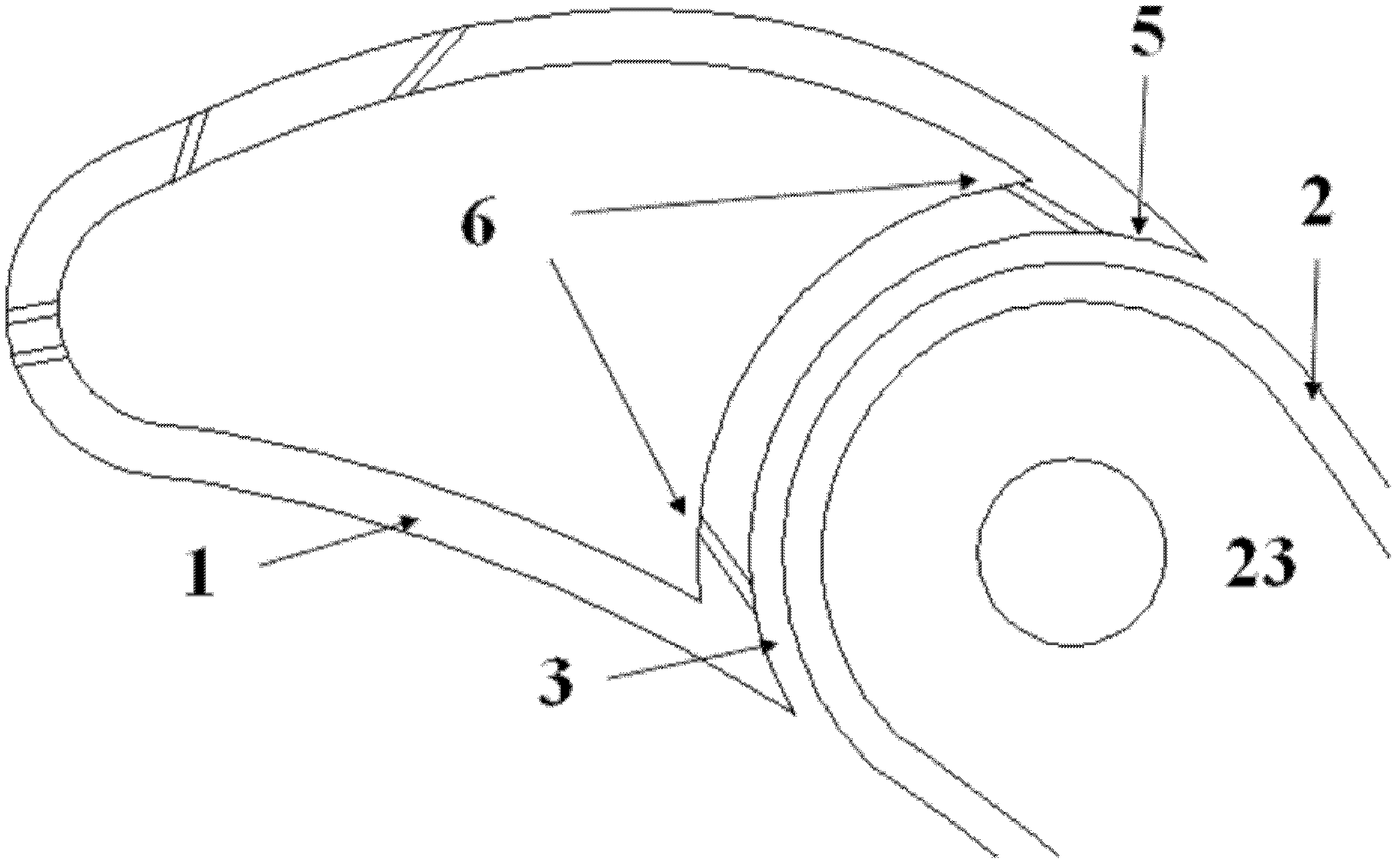

[0023] Embodiment 1: A cold air slot 6 is set up on the wall 5 where the front section 1 of the guide vane is in the gap 3 to spray the cold air. For the specific schematic diagram, see image 3 . A total of two rows of cold air slots 6 are arranged, one row is close to the side of the pressure surface 18 to spray cold air, and the other row is close to the side of the suction surface 19 to spray cold air. Since the pressure difference between the pressure side and the suction side of the gap 3 is very small, the pressure difference between the pressure side and the suction side of the gap 3 can be ignored, and the leakage flow from the pressure side to the suction side of the gap 3 and the corresponding countermeasures can be ignored. The cold air 7 eventually forms an adverse effect of an effective air film on the surface of the rear section 2, so the distances between the two rows of cold air slots are the same from their respective outlets. The width of the two rows of co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com