Patents

Literature

30results about How to "Prevent "stuck" and other phenomena" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

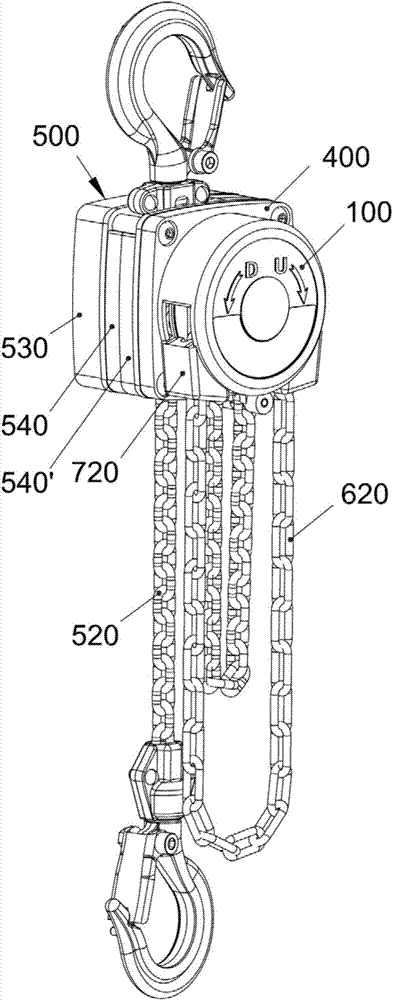

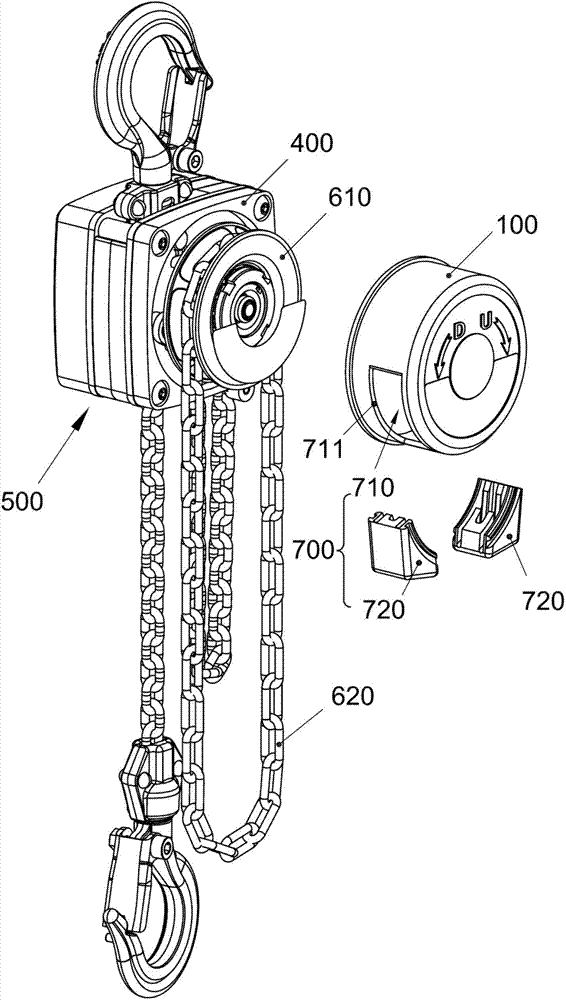

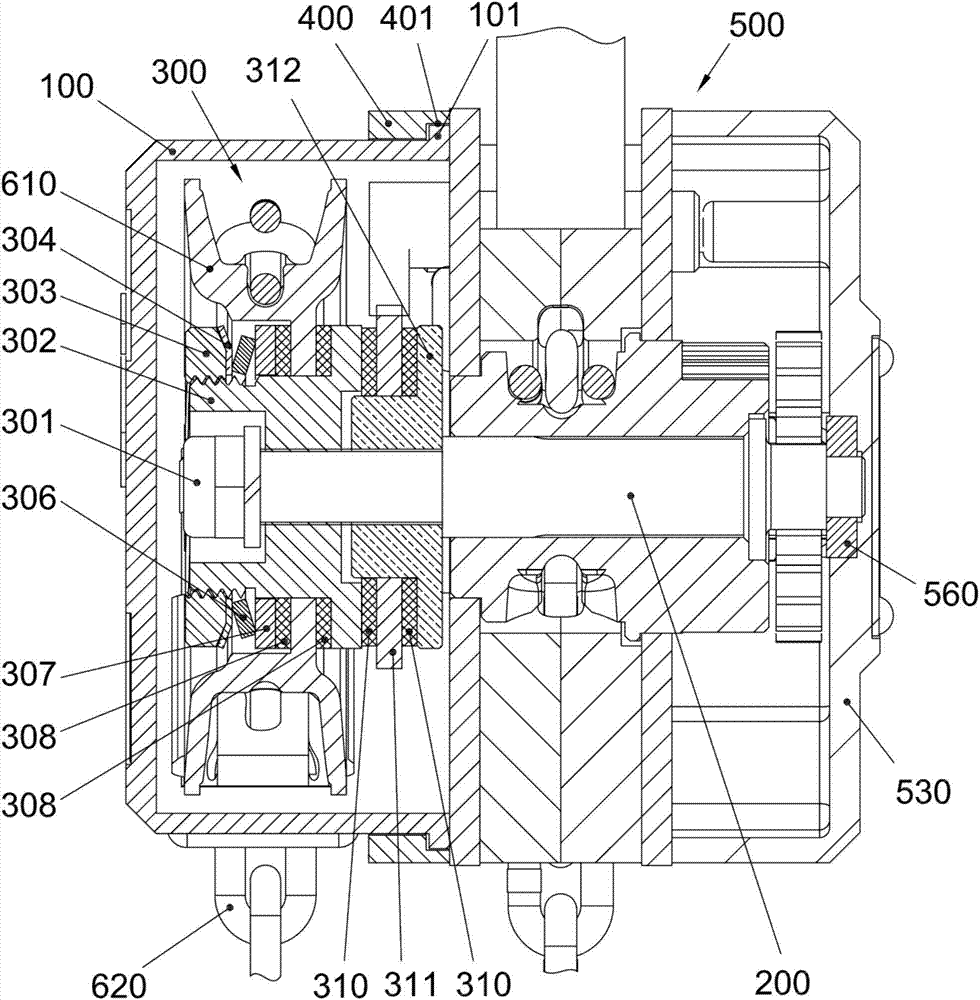

Chain block

Owner:CHONGQING VITAL ELEVATORING EQUIP

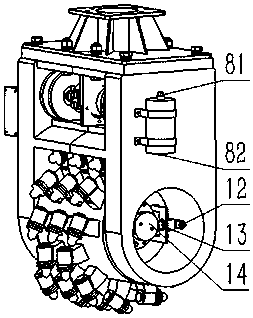

Mining head suitable for exploiting deep-sea cobalt-rich crust

PendingCN109798118AApplicable miningExtended service lifeDisloding machinesMineral miningEngineeringCutting force

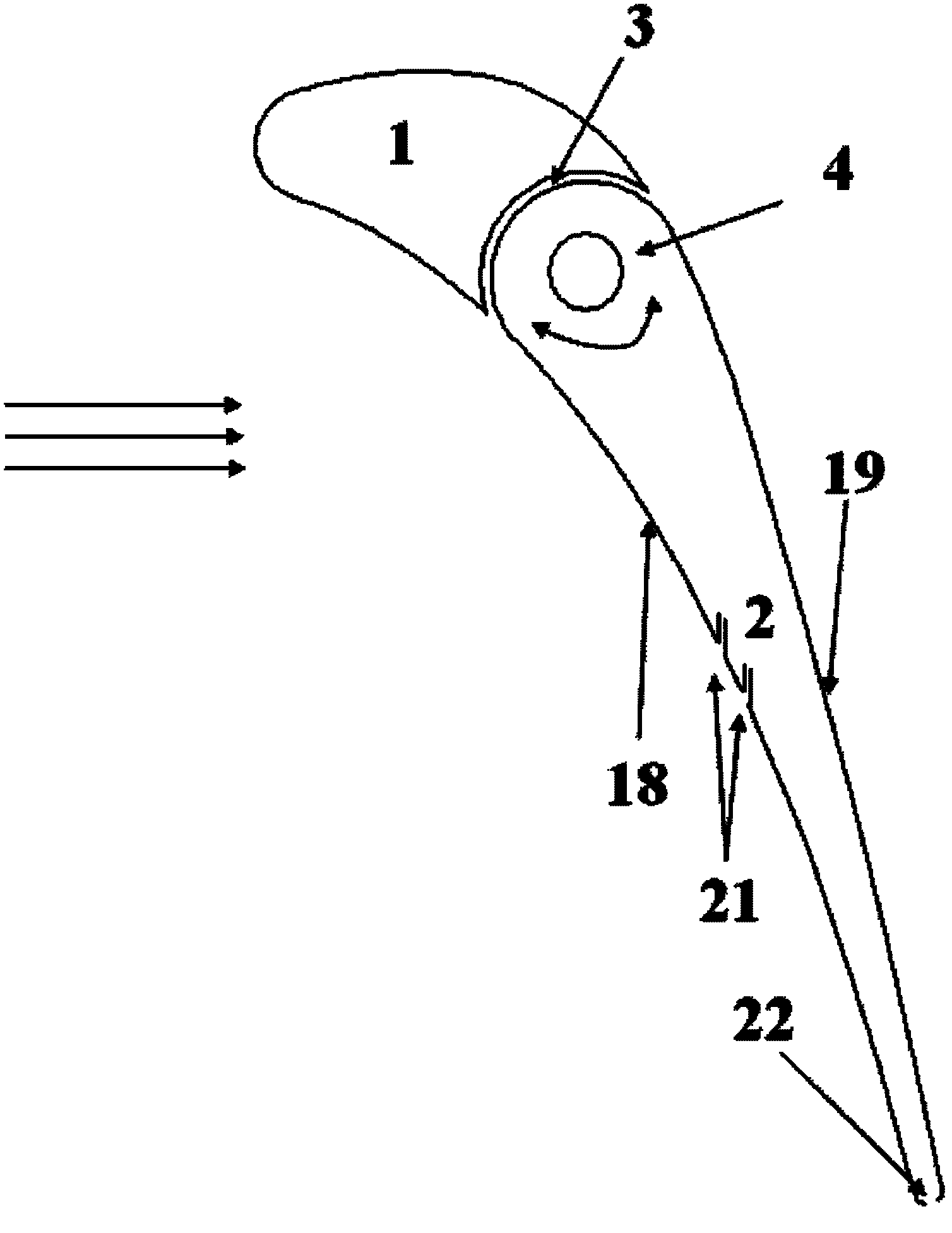

The invention relates to a mining head suitable for exploiting a deep-sea cobalt-rich crust. The mining head comprises a pick component and is characterized in that the pick component is arranged on the wall of a milling and digging roller, a spindle penetrates the milling and digging roller and is fixed to a milling and digging rack, a milling and digging motor is fixed to the milling and diggingrack, the milling and digging rack is further provided with a compensator, a first leather bag and first springs are arranged in the compensator, the first leather bag is filled with oil, the first springs are arranged on two sides of the first leather bag, and the bottom of the compensator is provided with a compensation oil port; two ends of the spindle are provided with bearings, a left bearing cavity exhaust port is arranged in a left bearing cavity, a right bearing cavity exhaust port and a right bearing cavity oil supplementing port are arranged in the right bearing cavity, the spindleis provided with an oil hole, the left bearing cavity and the right bearing cavity are communicated through the oil hole, and the compensation oil port is communicated with the right bearing cavity oil supplementing port. The mining head has the advantages that the mining head can adapt to deep-sea areas within 6000m; by a self-adaptation frequency-variable excitation function, crushing cutting force fluctuation range is lowered, pick service life is prolonged, and milling, digging and crushing efficiency is increased.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

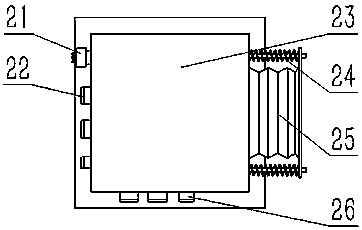

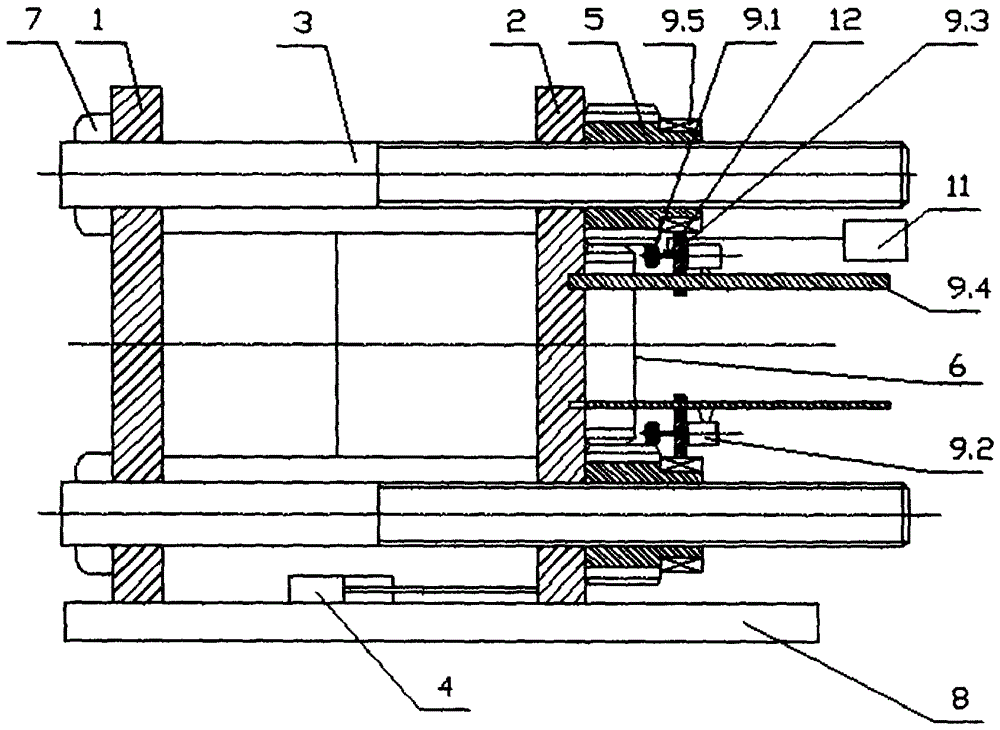

Large-angle small-gap side core-pulling mechanism of angle-ejector-type oblique sliding block of injection mold

Disclosed is a large-angle small-gap side core-pulling mechanism of an angle-ejector-type oblique sliding block of an injection mold. The large-angle small-gap side core-pulling mechanism includes anupper composite plate and a lower composite plate. A mold cavity is formed below the upper composite plate. Support blocks are arranged on the lower composite plate. An upper ejector retainer plate, alower ejector retainer plate and an ejector are arranged on the lower composite plate between the support blocks. A backing plate is arranged on each support block. A mold core is arranged on each backing plate. Injection molded plastic parts are arranged between the mold cores and the mold cavity. An inverted hook is arranged below each plastic part. Retaining ribs are correspondingly arranged on the front side and the lower side of each inverted hook. The large-angle small-gap side core-pulling mechanism is characterized in that direct-ejector rods are arranged on the upper ejector retainerplate and the lower ejector retainer plate, a mounting hole is formed in each mold core, a sliding block seat is arranged in each mounting hole, an oblique sliding seat is arranged on each sliding block, a sliding slot is formed in one side of each oblique sliding seat, a penetrating hole is formed in each oblique sliding seat, a guiding pushing block is arranged in each penetrating hole, the direct-ejector rods penetrate through the sliding block seats and are fixed to the guiding pushing blocks, an oblique sliding block is arranged on one side of each oblique sliding seat, the upper part ofeach oblique sliding block is matched with the inverted hook of the corresponding plastic part, a sliding rail is arranged on one side of each oblique sliding block, the sliding rails are matched with the sliding slots, an inserting hole is formed in each oblique sliding block, and the inserting holes are connected with the guiding pushing blocks.

Owner:ZHEJIANG KAIHUA MOLDS

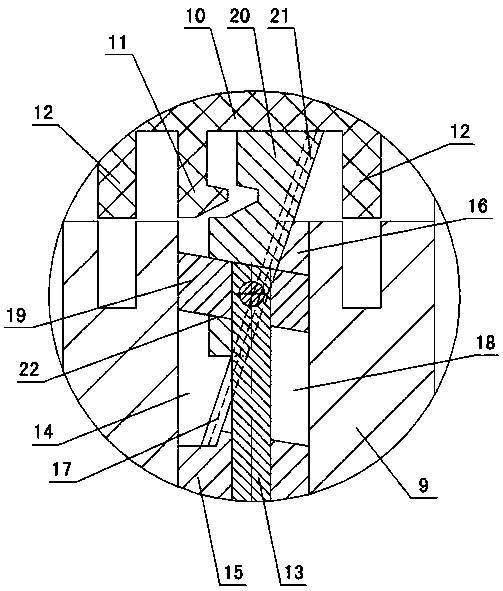

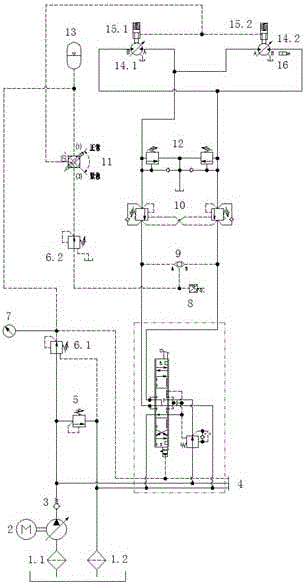

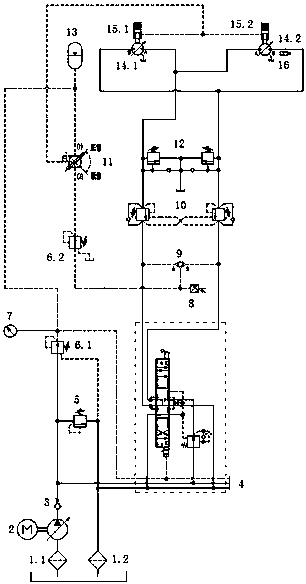

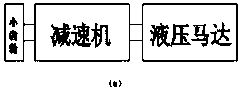

Novel hydraulic rotation mechanism of segment erector

ActiveCN106678090AGuaranteed stabilityGuaranteed accuracyUnderground chambersServomotorsHydraulic motorEquilibrium control

The invention relates to a novel hydraulic rotation mechanism of a segment erector. The novel hydraulic rotation mechanism comprises a filter, a plunger pump, a check valve, an electric-hydraulic proportional direction valve, an overflow valve, a first pressure reduction valve, a second pressure reduction valve, a pressure gauge, a pressure sensor, a shuttle valve, a balance valve, a three-position ball valve, a two-way overflow valve, an energy accumulator, two hydraulic motors, a brake and a rotary encoder. A balance control module of the hydraulic motors is composed of the balance valve and the two-way overflow valve, and two-way safety protection can be provided; the pressure compensation type electric-hydraulic proportional direction valve with loads is selected for use, and precision and stability of the splicing position are ensured; the hydraulic motors with mechanical braking are adopted, and reliability of rotation movement is ensured; and the hydraulic impact generated in the start, stop and reversing processes of the segment erector is eliminated, the device damage situation such as the situation that the novel hydraulic rotation mechanism gets stuck is effectively prevented in the movement process, and the operation efficiency is improved.

Owner:辽宁三三工业有限公司

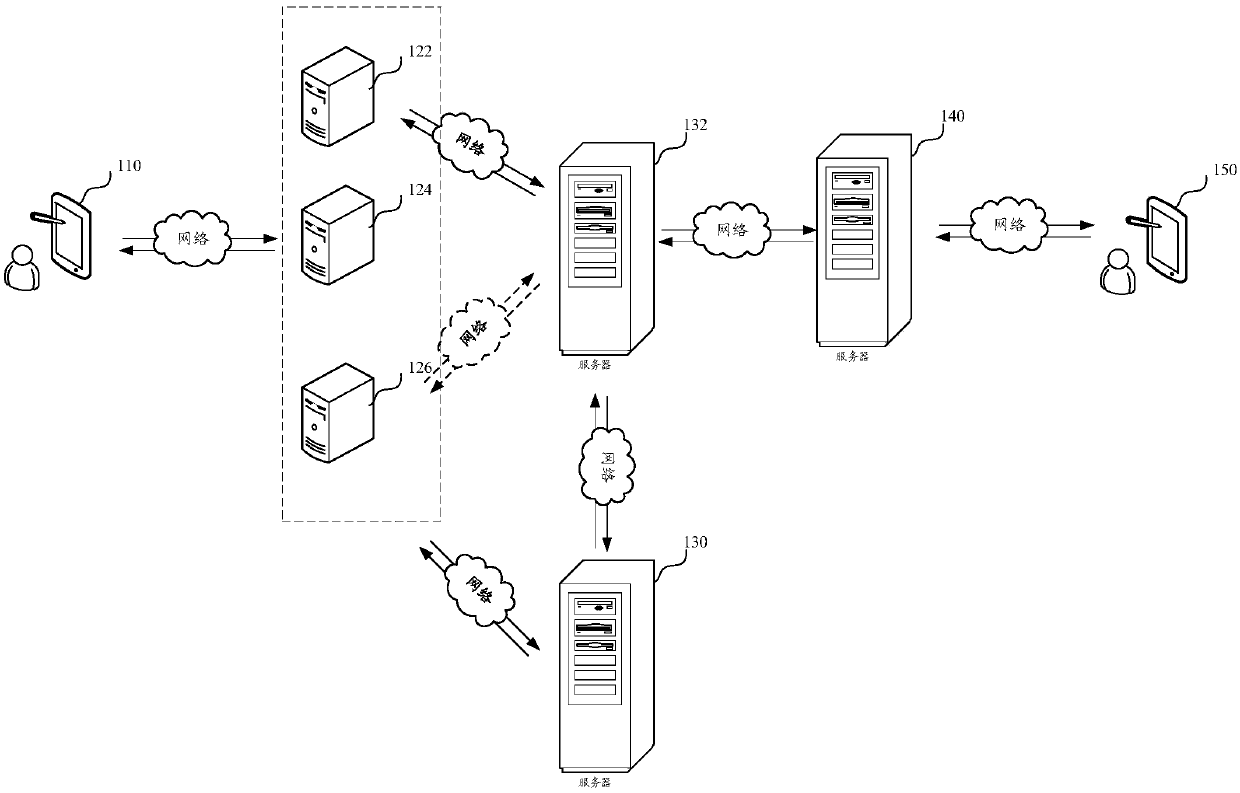

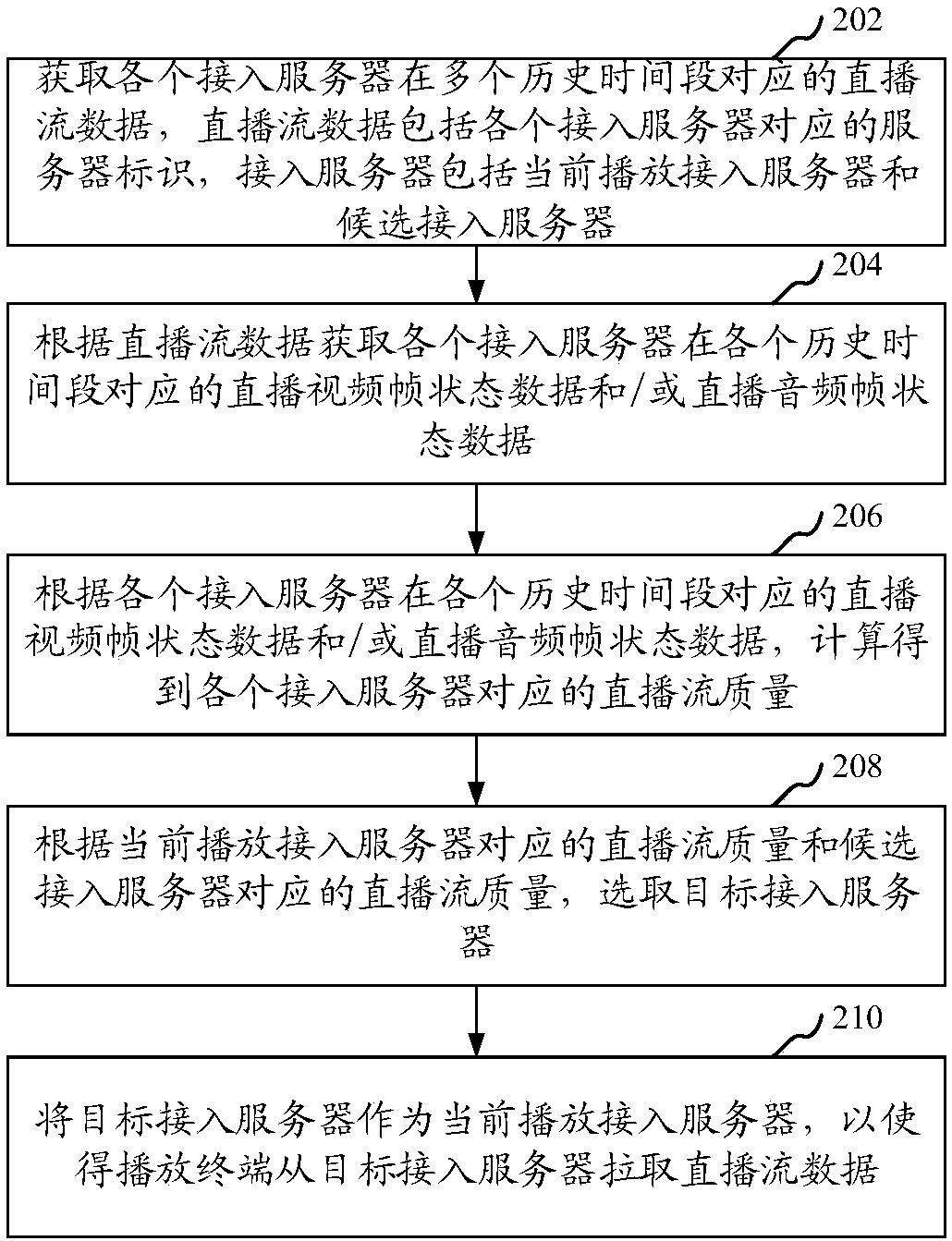

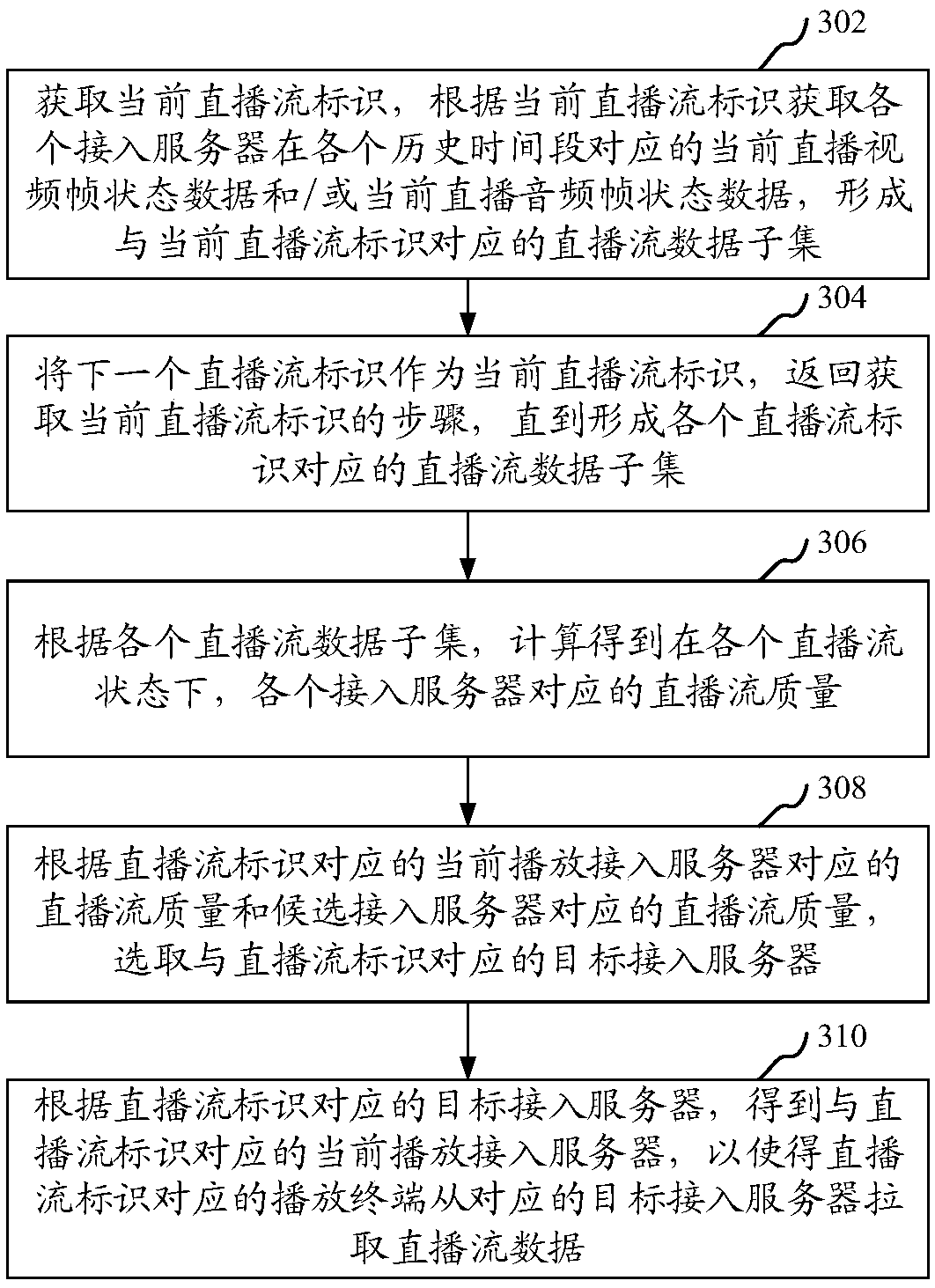

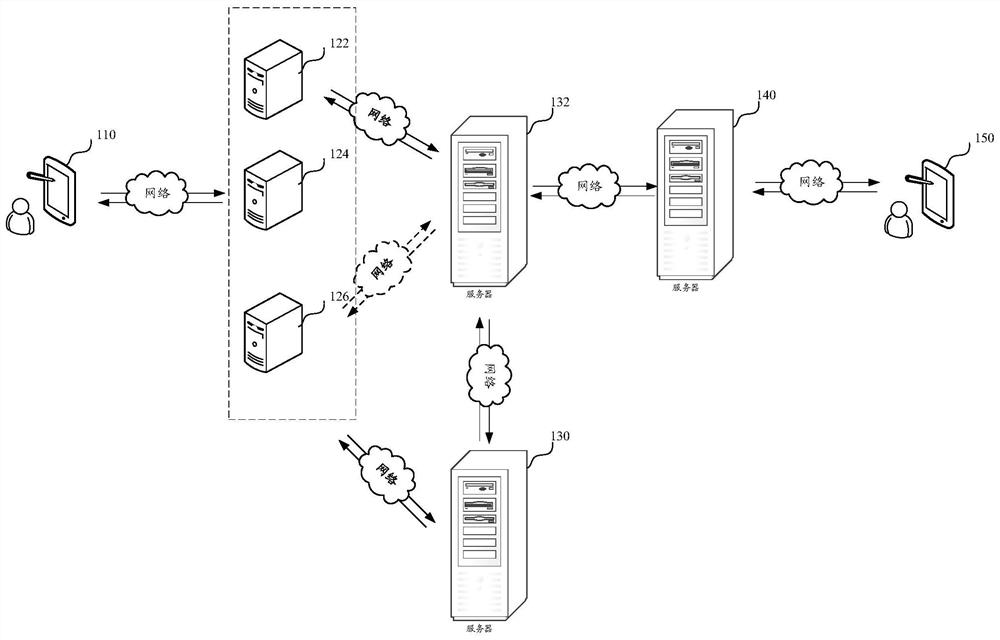

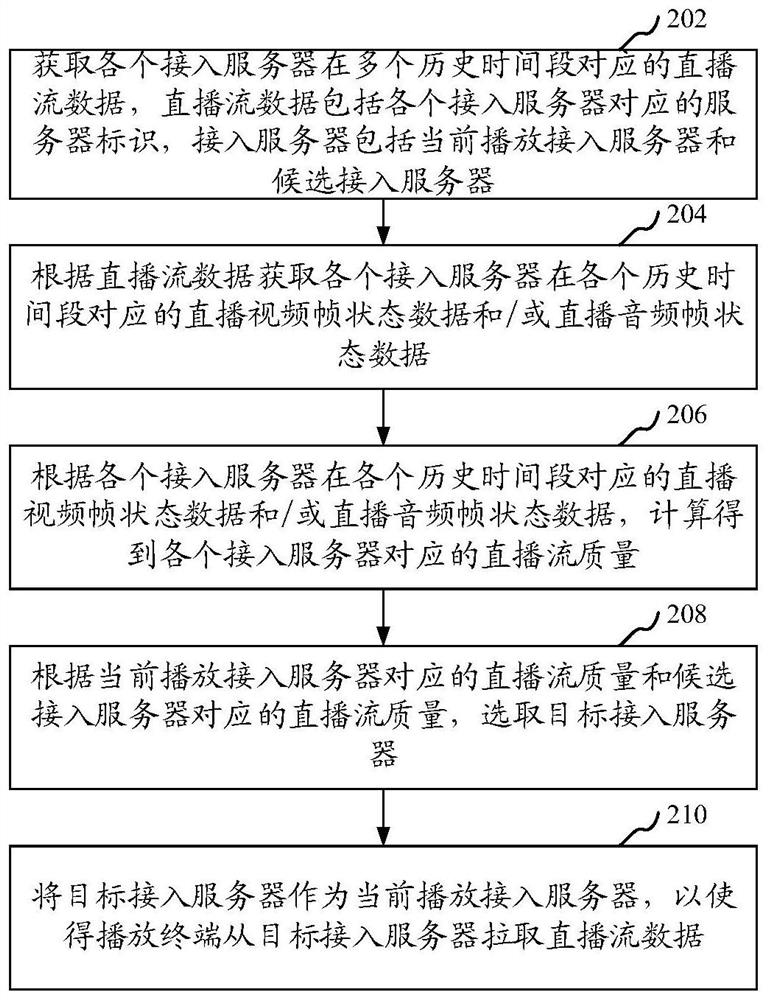

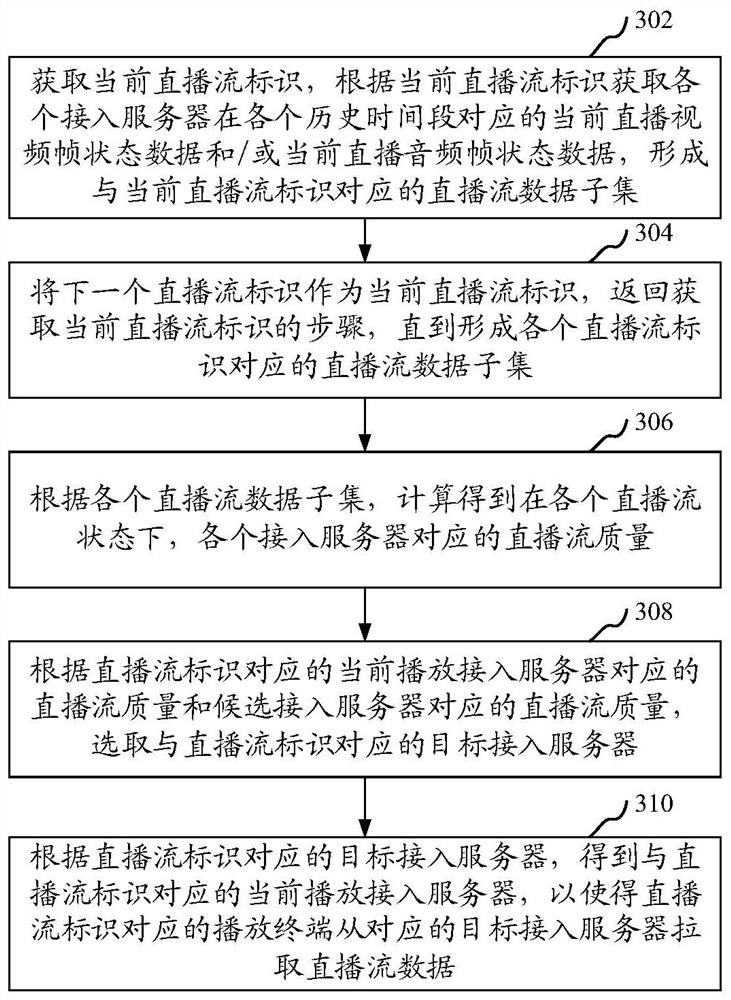

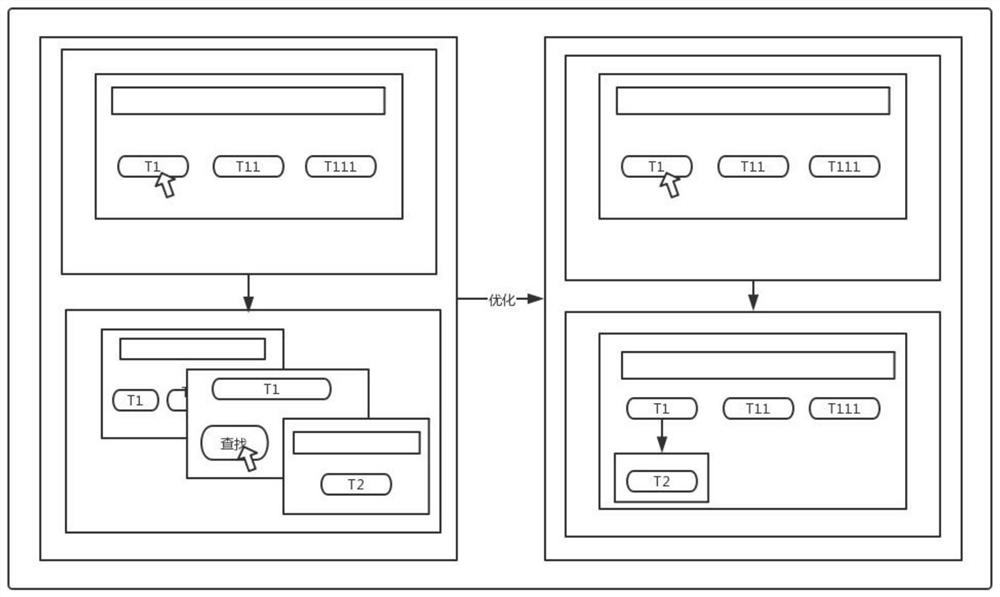

Live broadcast switching method and device, computer equipment and storage medium

ActiveCN110213596APrevent stuck and other phenomenaTransmissionSelective content distributionStream dataLive video

The invention relates to a live broadcast switching method and device, a computer readable storage medium and computer equipment. The method comprises the following steps: obtaining live broadcast stream data corresponding to each access server in a plurality of historical time periods, and obtaining live broadcast video frame state data and / or live broadcast audio frame state data corresponding to each access server in each historical time period according to the live broadcast stream data; according to the live video frame state data and / or the live audio frame state data corresponding to each access server in each historical time period, performing calculating to obtain live streaming quality corresponding to each access server; selecting a target access server according to the live stream quality corresponding to the current playing access server and the live stream quality corresponding to the candidate access server; and taking the target access server as a current playing accessserver, so that the playing terminal pulls the live broadcast stream data from the target access server. According to the scheme provided by the invention, the live broadcast switching accuracy can be improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Cooling method used for segmented geometric adjustment of guide vanes of gas turbine

ActiveCN102606312APrevent stuck and other phenomenaPrevent intrusionTurbine/propulsion engine coolingTrailing edgeGas turbines

The invention discloses a cooling method used for the segmented geometric adjustment of guide vanes of a gas turbine. Cool air is sprayed to the surface of the rear section of the vane according to a certain angle from a front-section wall surface in an interval between the front section of the vane and the rear section of the vane, an effective cool air film is formed on the surface of the rear section of the vane, and simultaneously, the rear section of the vane can be cooled comprehensively by the combination of the air film cooling nearby a trailing edge and the crack seam cooling of the trailing edge, the cooling of the end surface of the rear section of the vane and the tight sealing of the intervals between the end surface of the rear section of the vane and a wheel hub as well as between the end surface of the rear section of the vane and a receiver can be realized by the cool air spraying of grooves of the end surfaces or the cool air spraying of a pressure surface nearby the end surface or a method of the combination of the cool air spraying of the grooves of the end surfaces and the cool air spraying of the pressure surface nearby the end surface; and the cooling and the tight sealing of the area can be realized effectively as the cool air is sprayed to the wall surfaces of the wheel hub and the receiver at the area nearby the junction of a shaft neck with the wheel hub and the receiver. According to the cooling method, the key areas in the segmented geometric adjustment can be cooled and sealed tightly and effectively with less cool air quantity, and the safe stability and the realizability of the geometric adjustment mode in the practical application can be improved.

Owner:BEIHANG UNIV

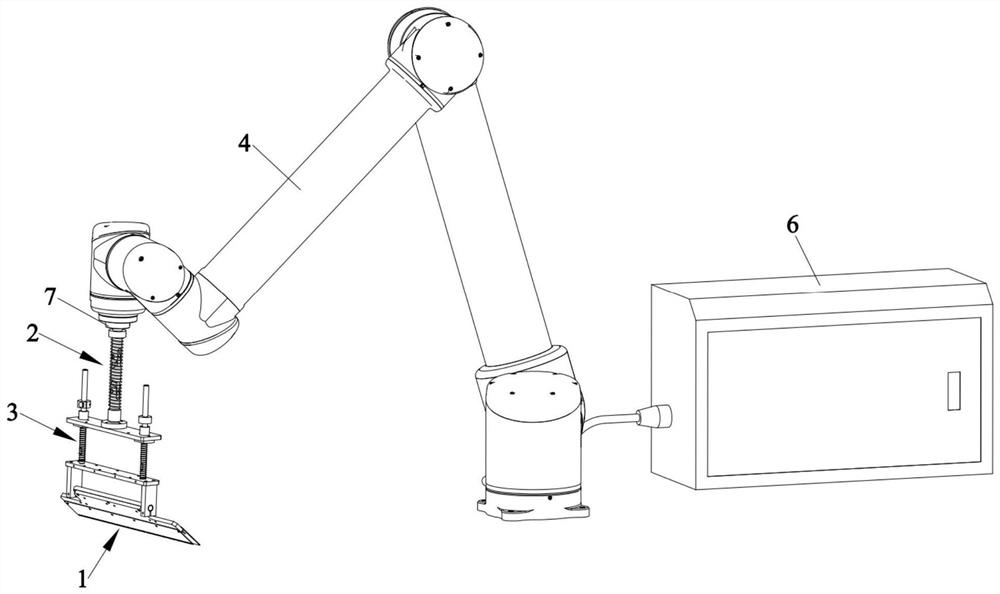

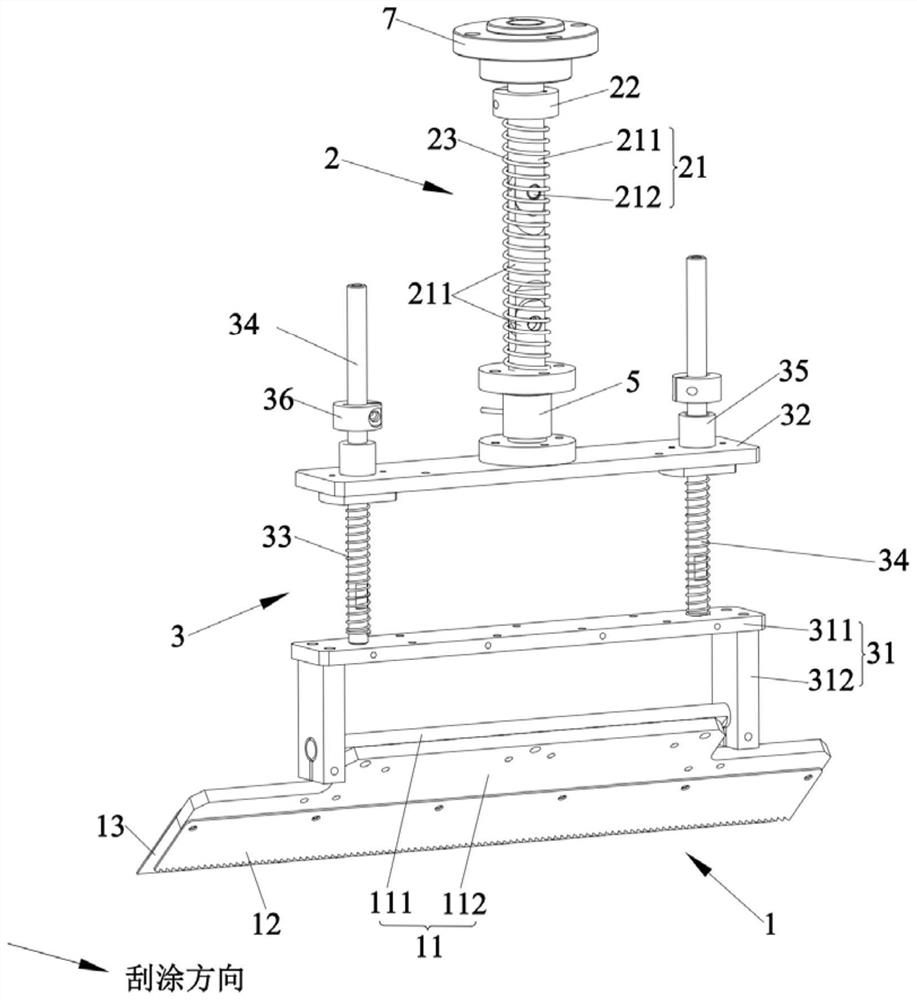

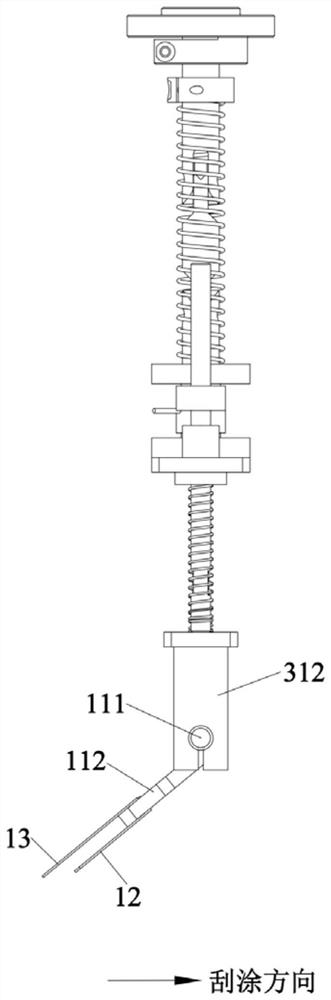

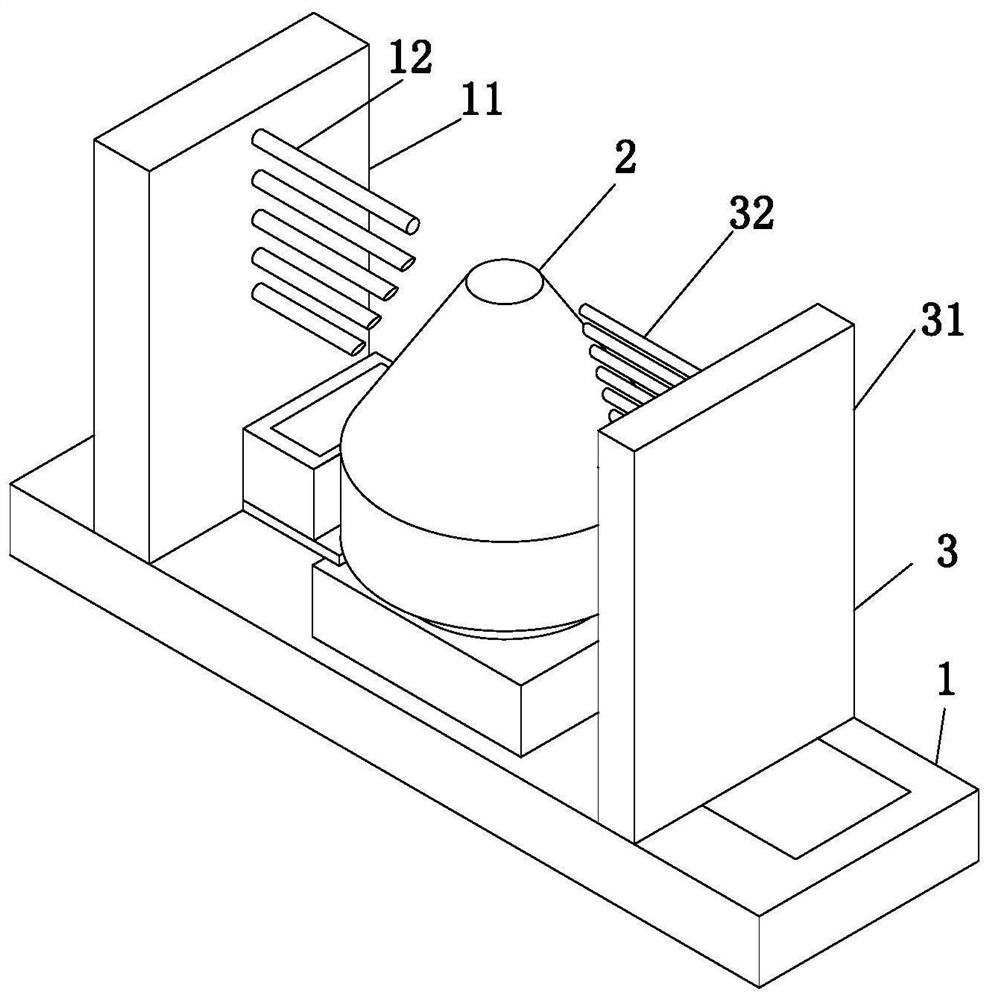

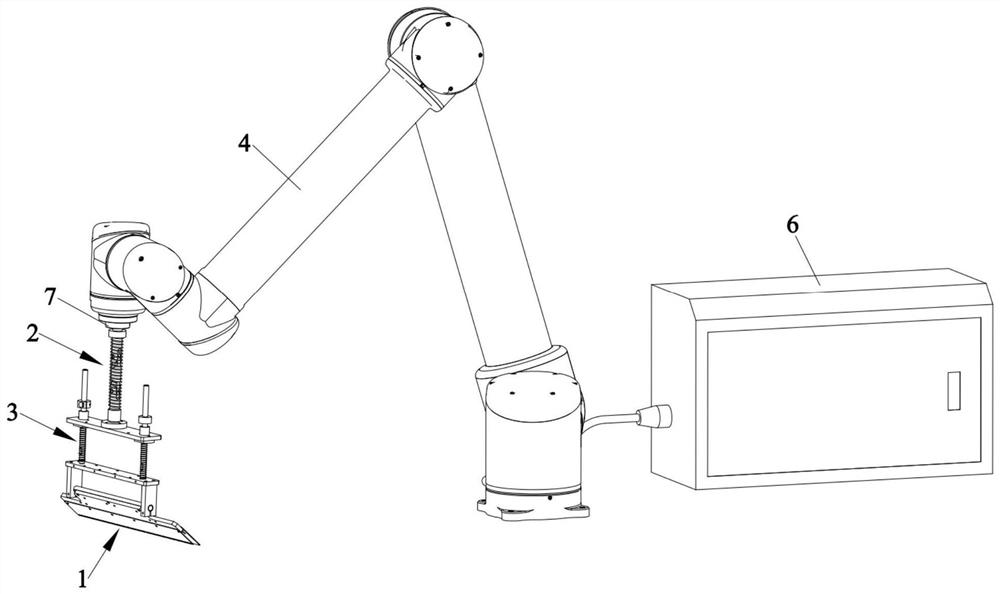

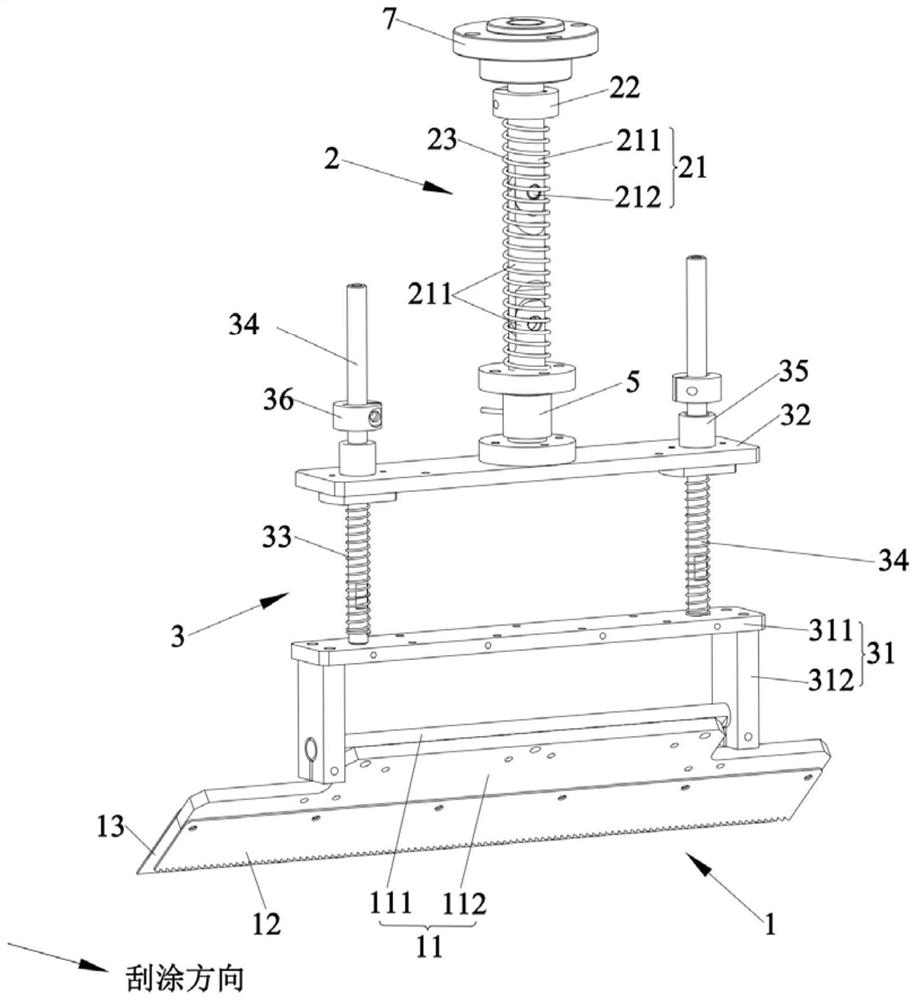

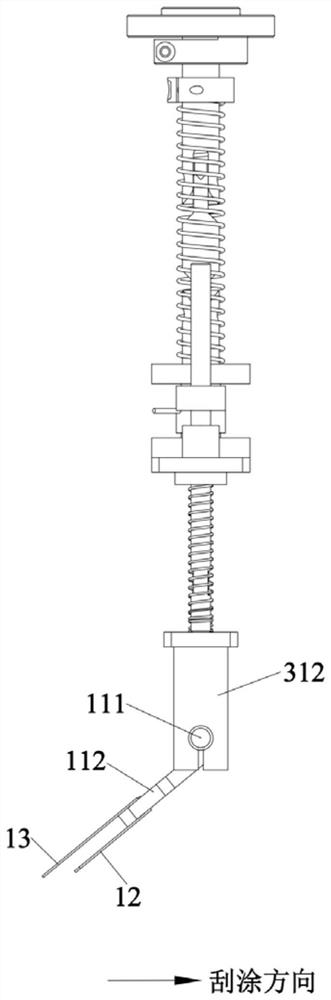

Floor paint blade coating device and floor paint coating robot

ActiveCN113374232AEnsure consistencyGuaranteed uniformityBuilding constructionsStructural engineeringMechanical engineering

The invention relates to the technical field of building machinery, and discloses a floor paint blade coating device and a floor paint coating robot. The floor paint blade coating device comprises a scraper mechanism, a first self-adaptive mechanism and a second self-adaptive mechanism. The second self-adaptive mechanism is arranged at the adjusting end of the first self-adaptive mechanism, and the scraper mechanism is arranged at the adjusting end of the second self-adaptive mechanism. When the scraper mechanism is subjected to external force, the adjusting end of one of the first self-adaptive mechanism and the second self-adaptive mechanism can rotate around a first axis, and the first axis is parallel to a scraping direction of the scraper mechanism, so that the scraper mechanism can be parallel to the ground through rotation, and the adjusting end of the other self-adaptive mechanism can ascend and descend in the vertical direction, so that the scraper mechanism can adapt to fluctuation of the ground through lifting. According to the floor paint blade coating device, the scraper mechanism can be self-adaptively adjusted according to change of ground condition, so that consistency of blade coating thickness is ensured, and blade coating quality and blade coating efficiency of the floor paint are improved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

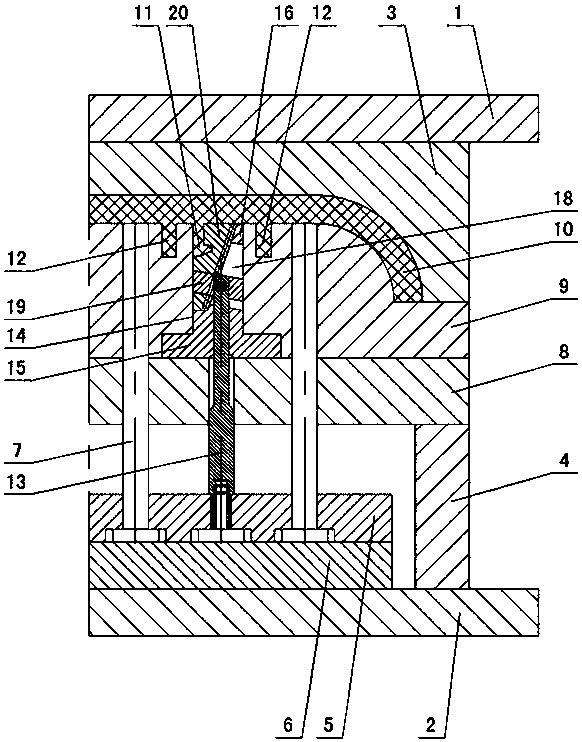

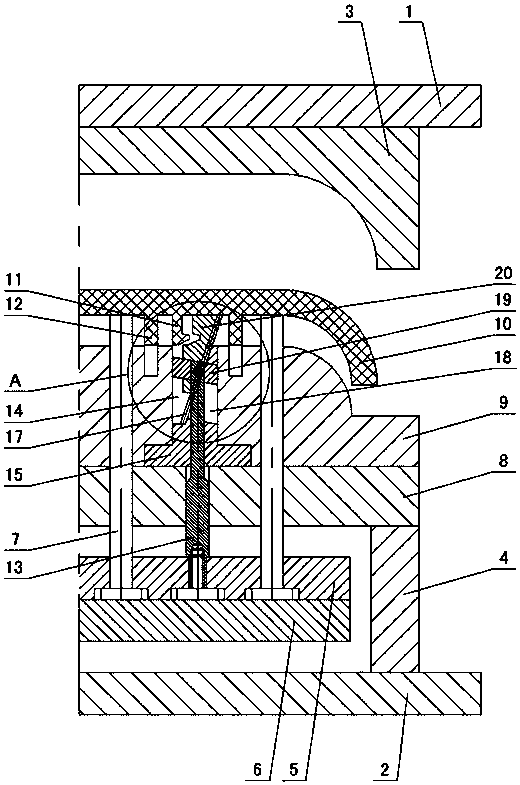

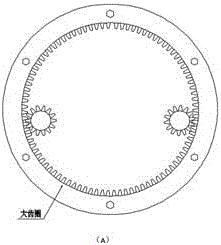

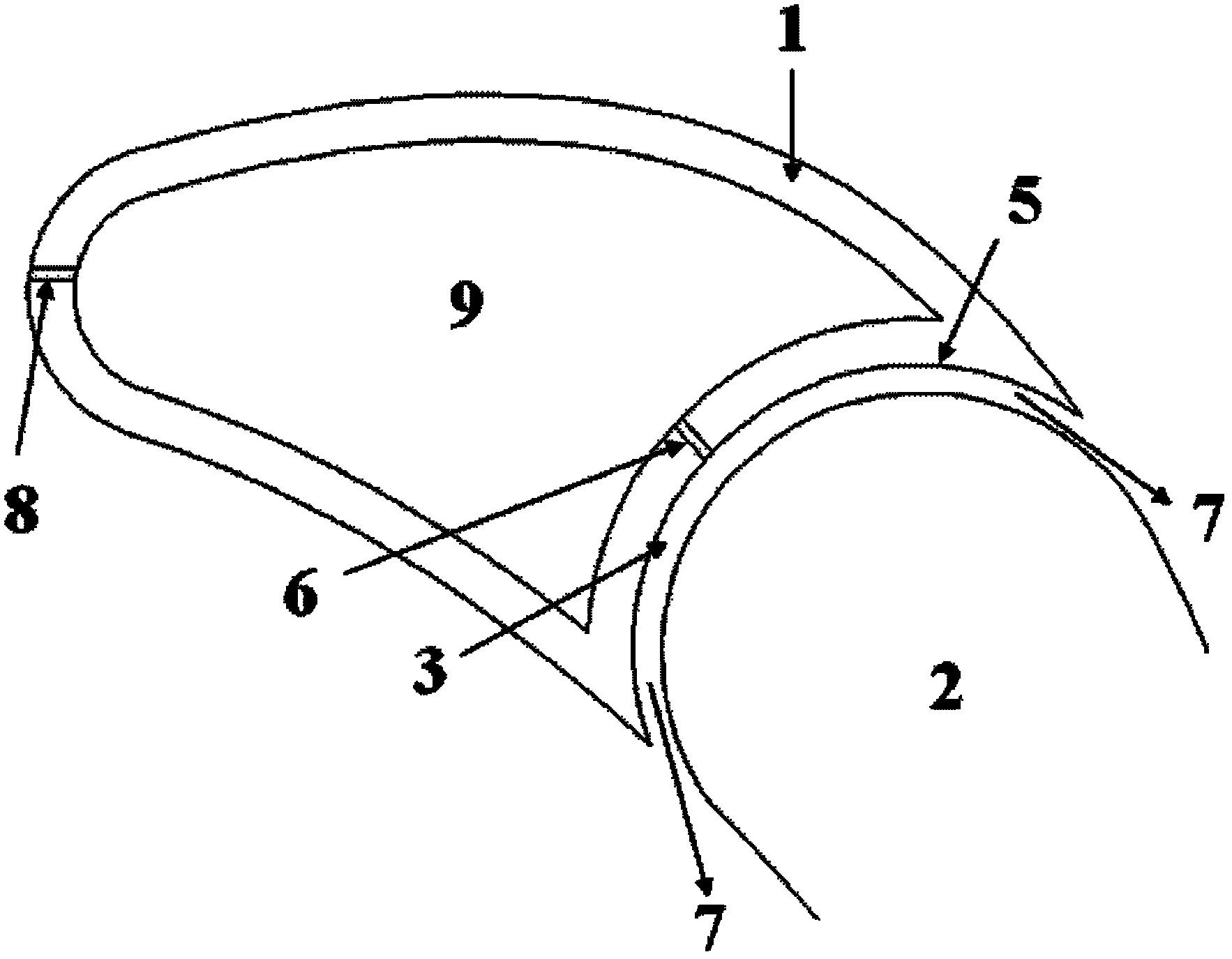

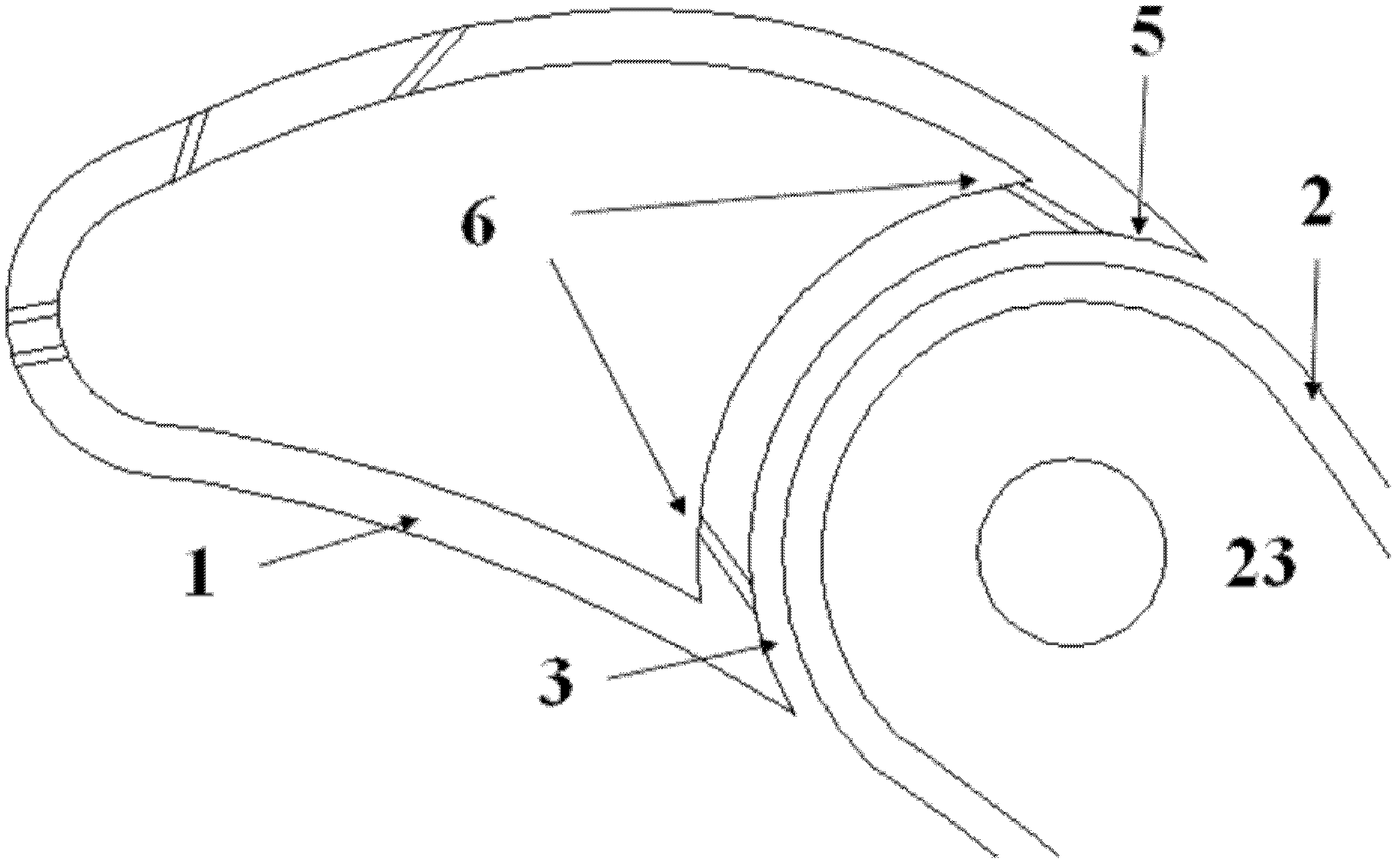

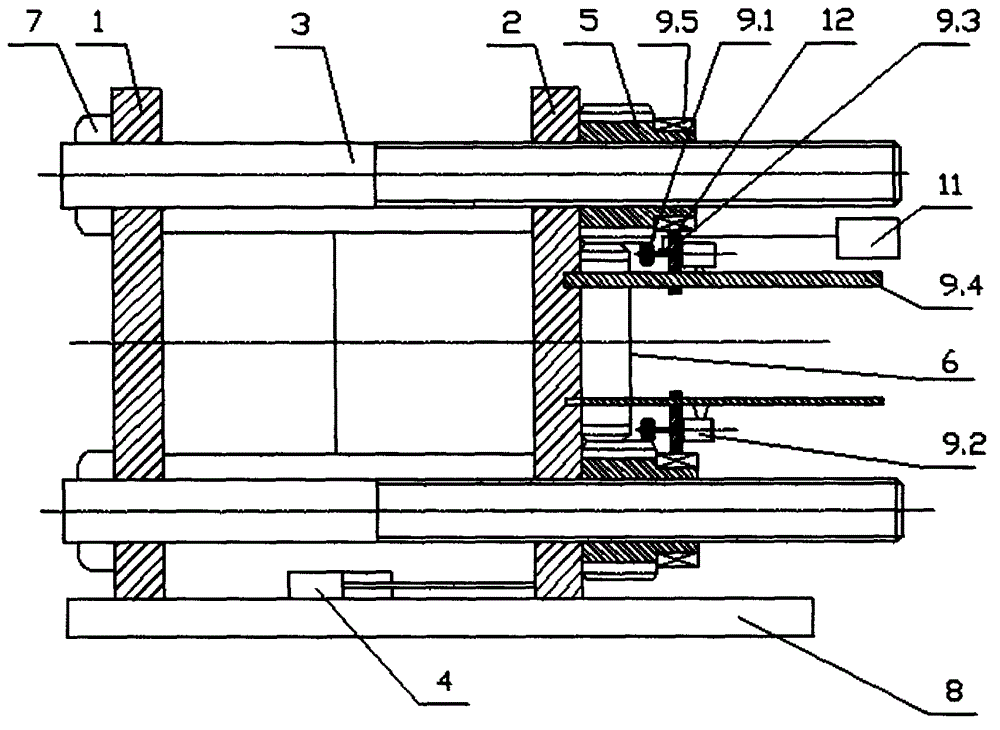

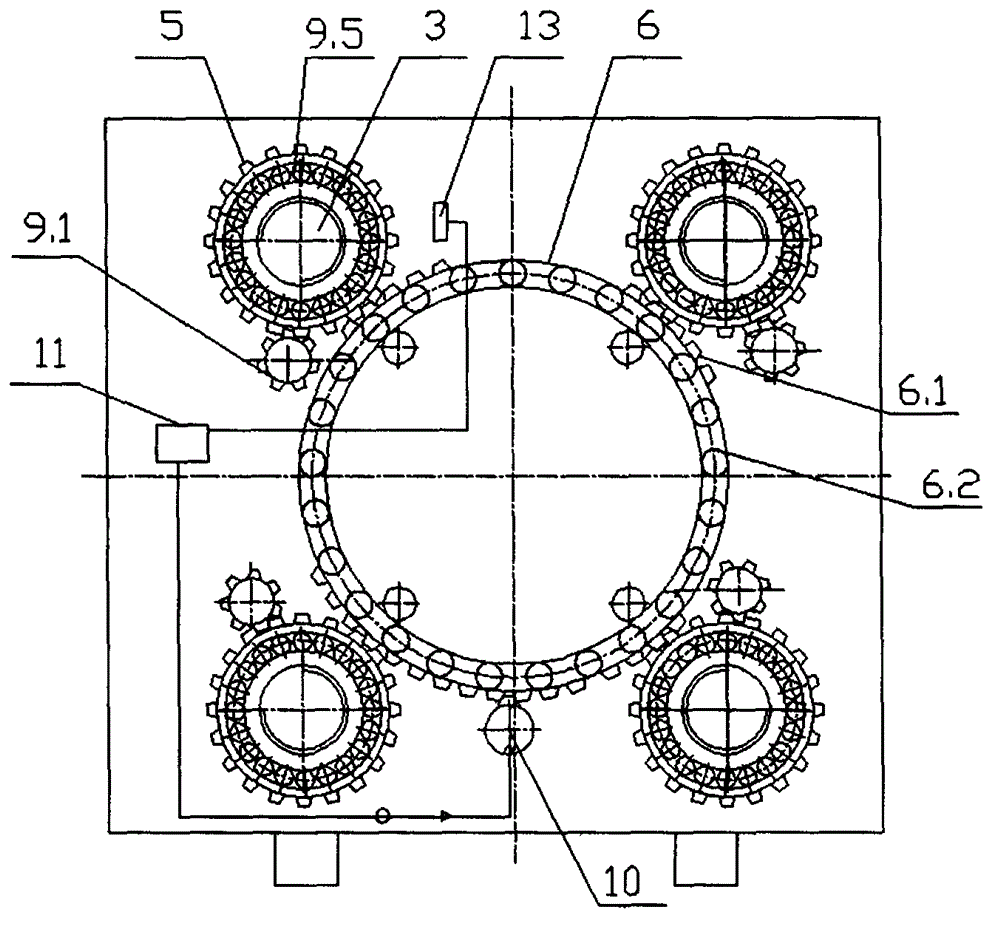

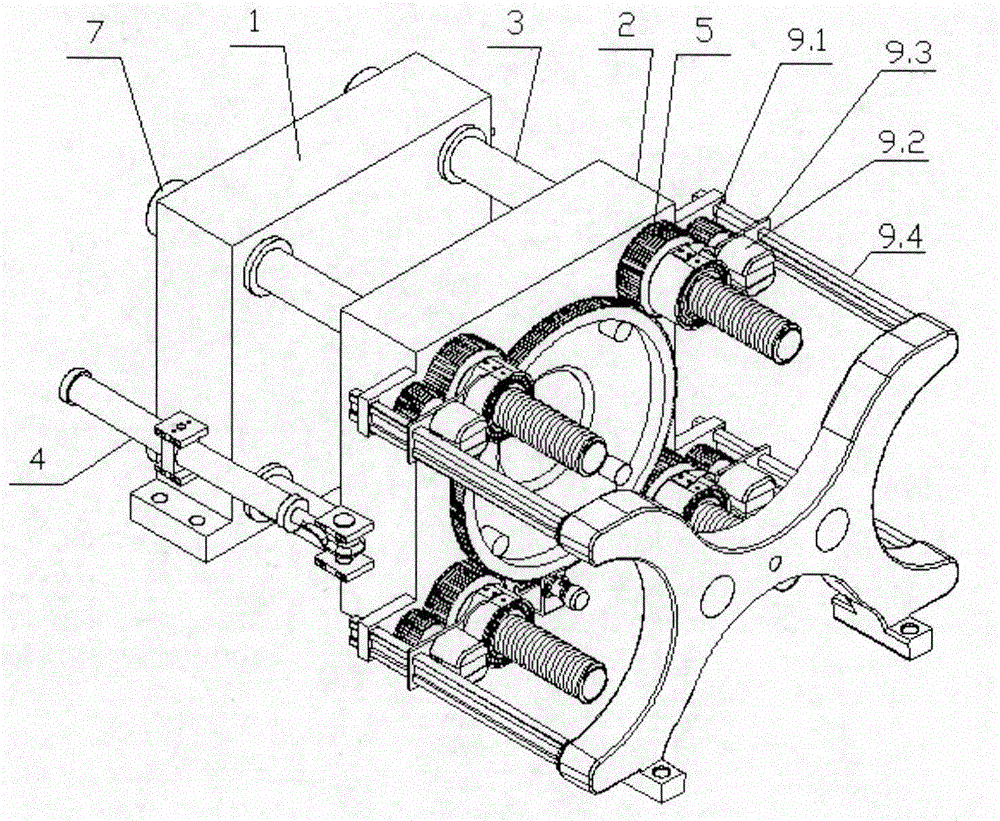

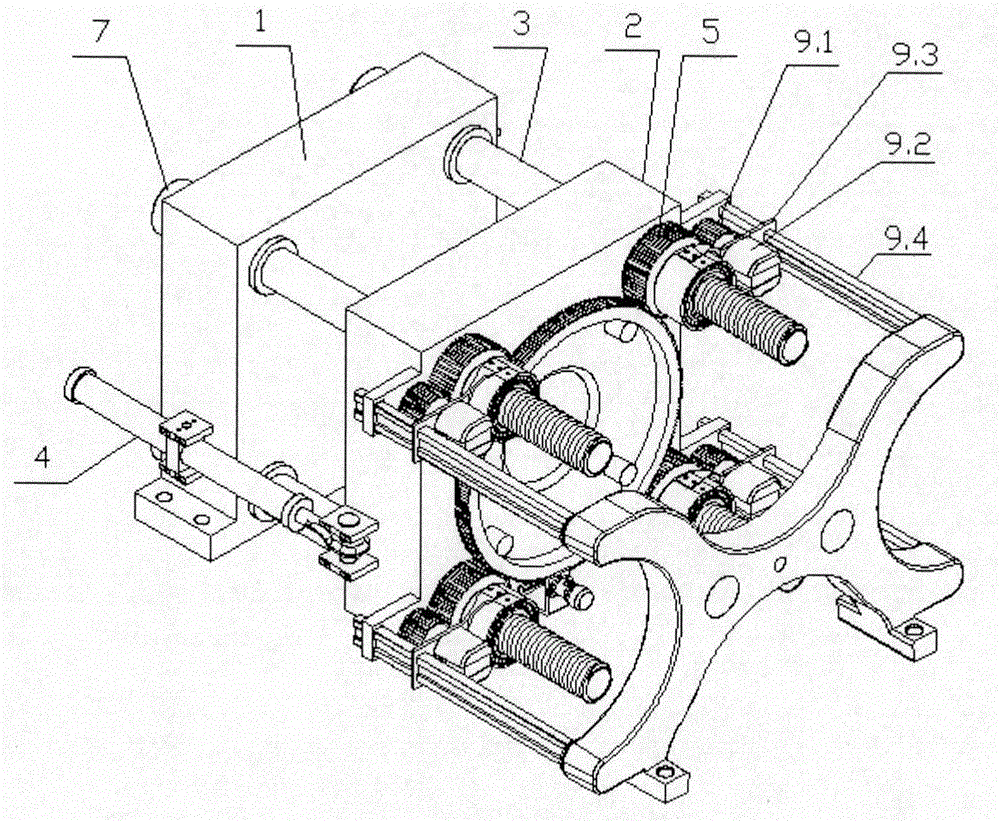

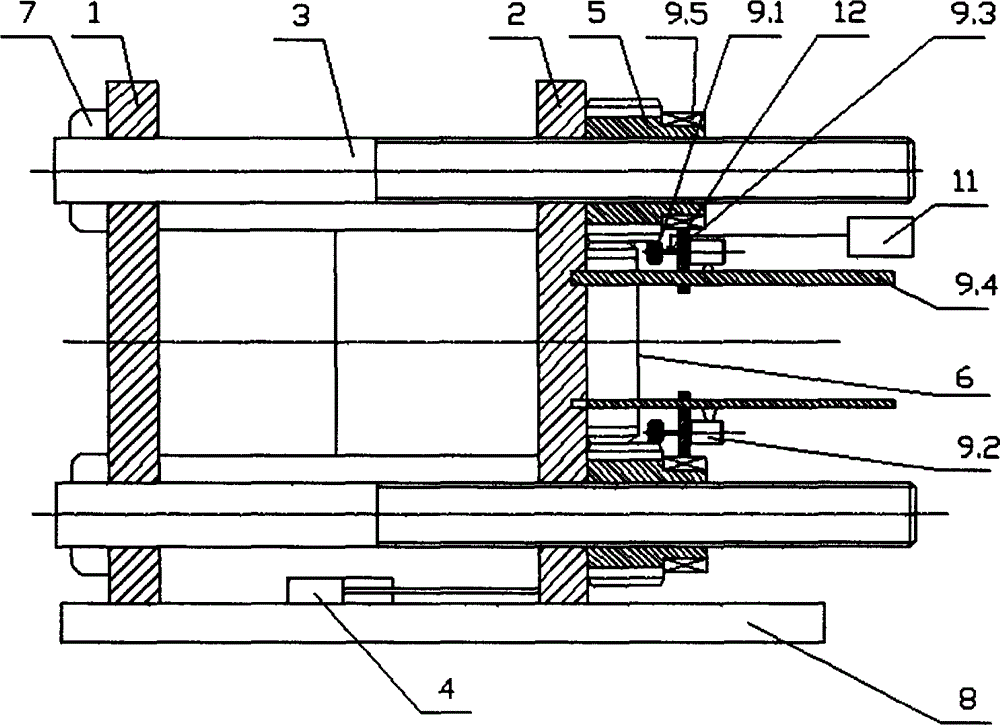

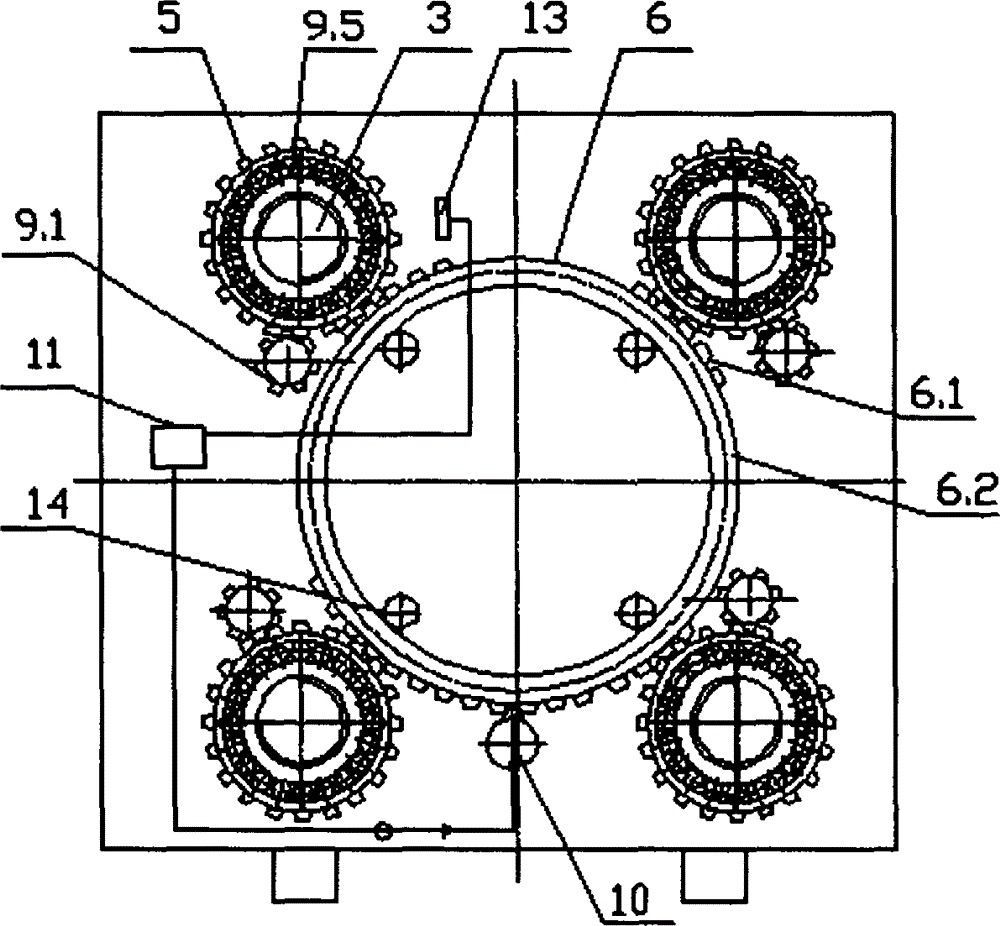

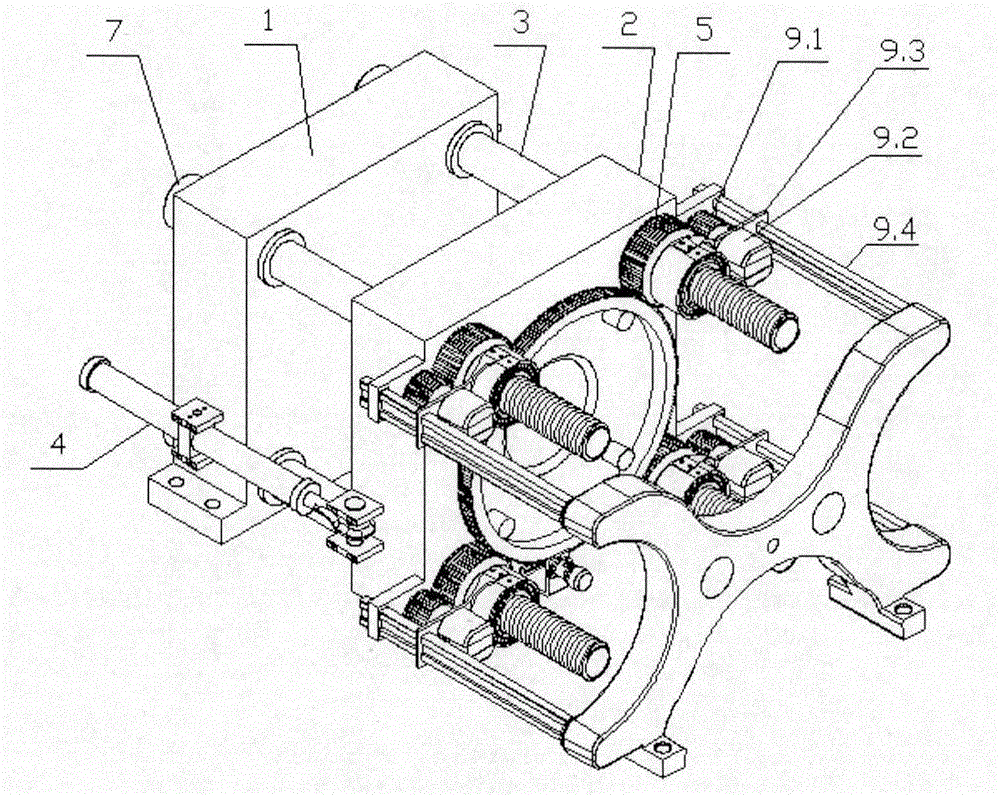

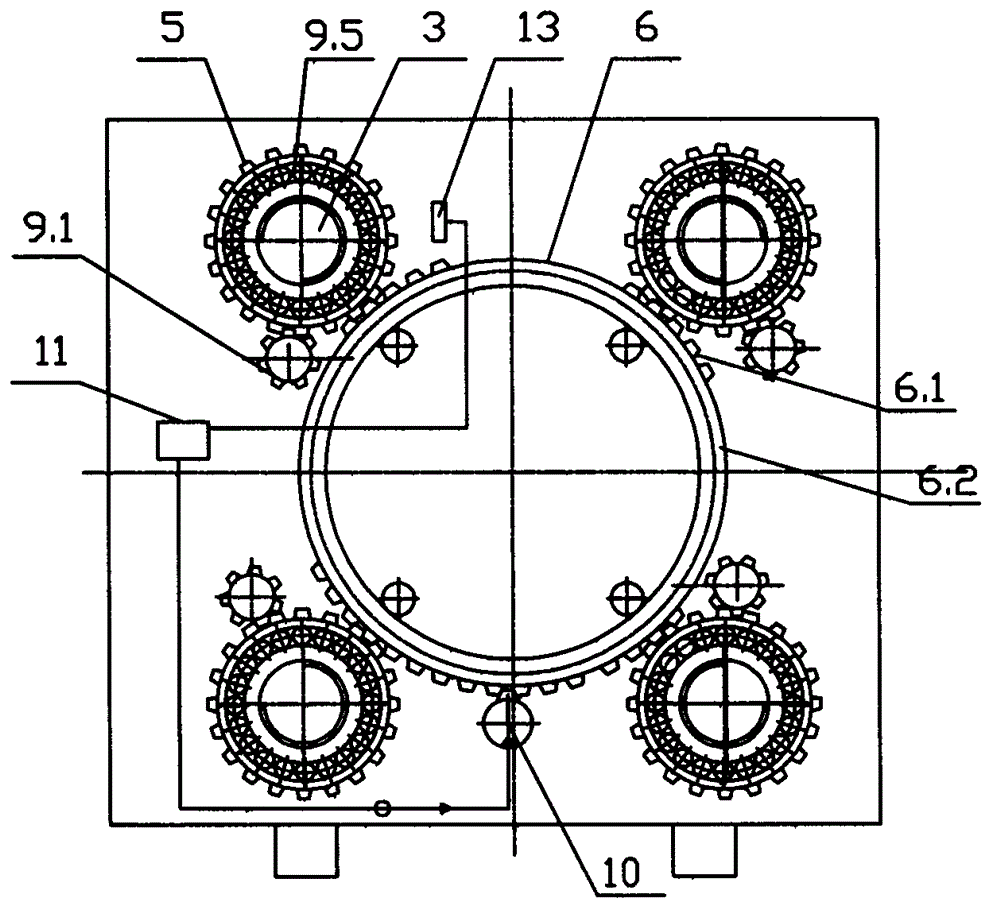

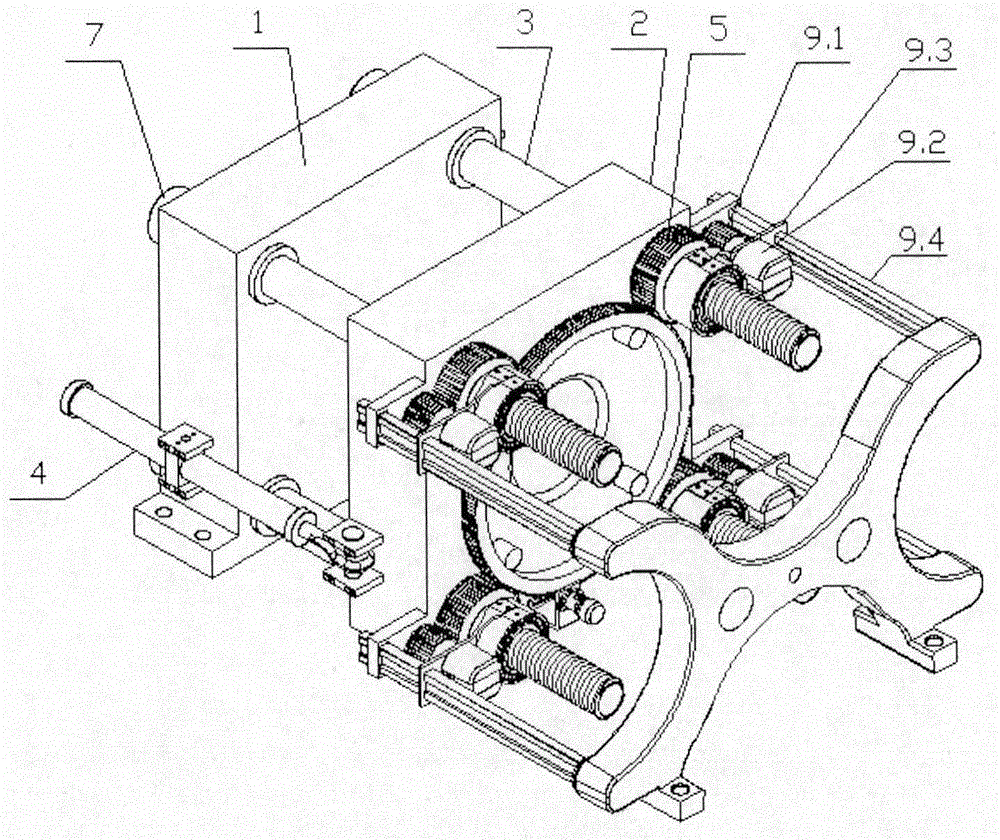

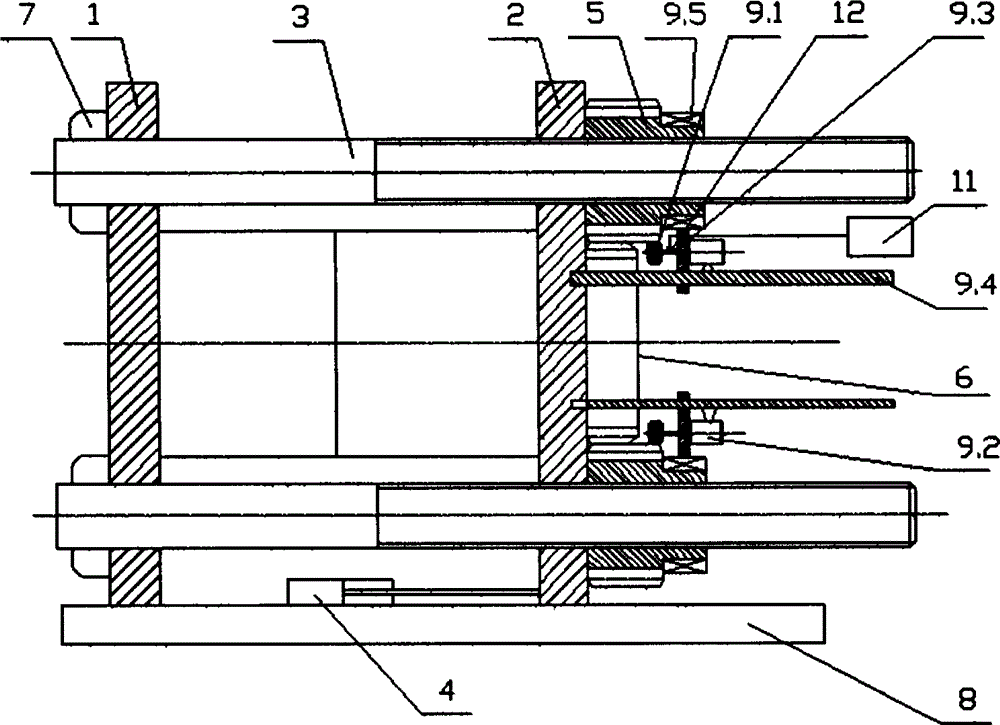

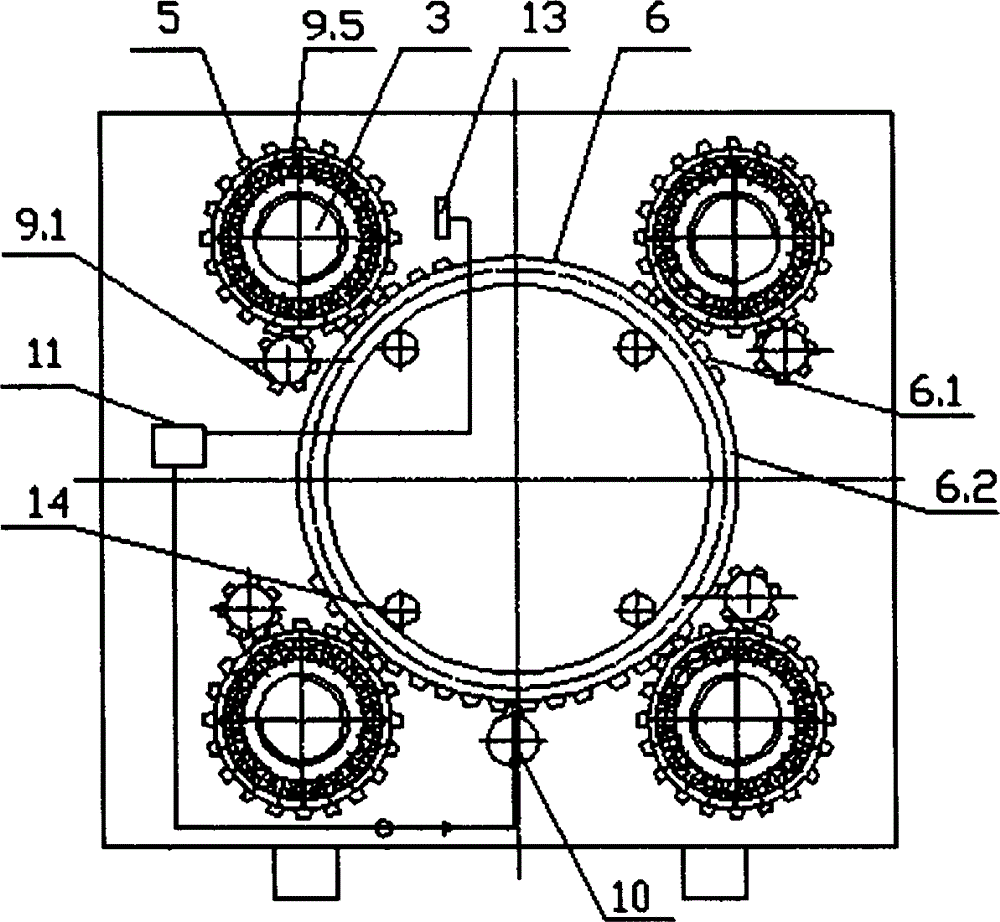

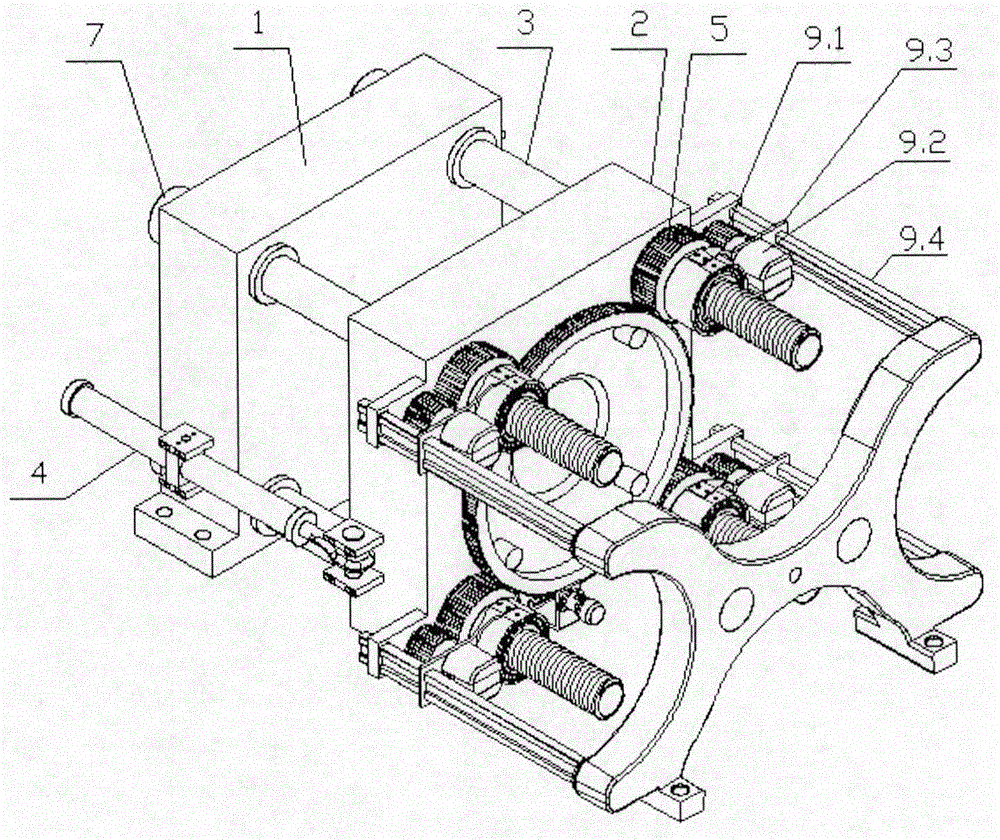

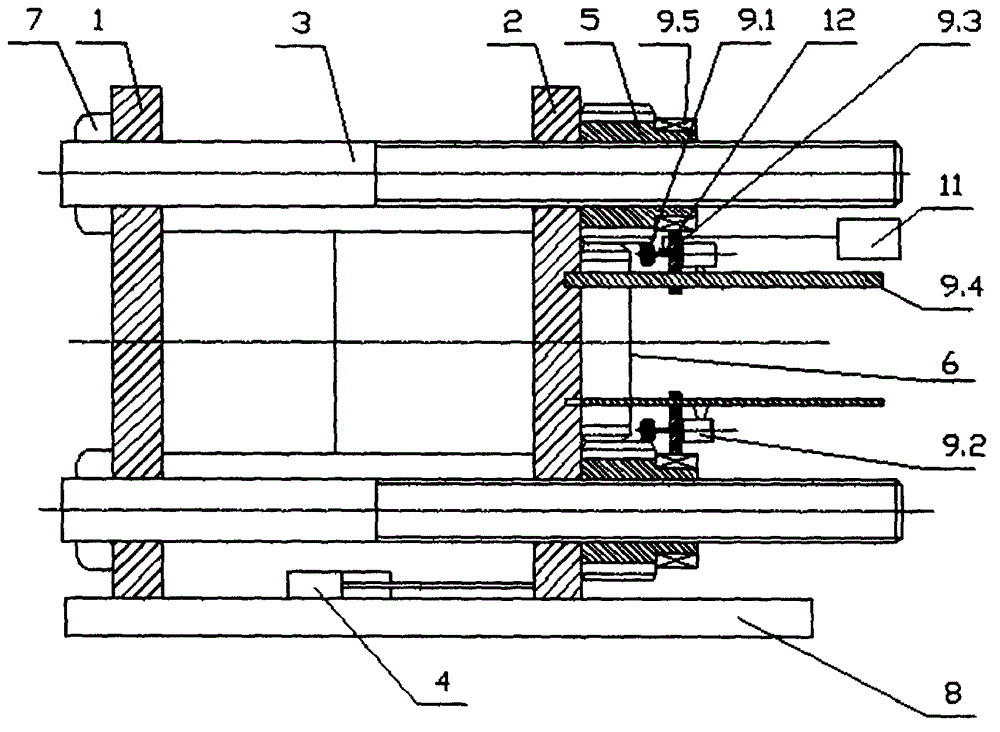

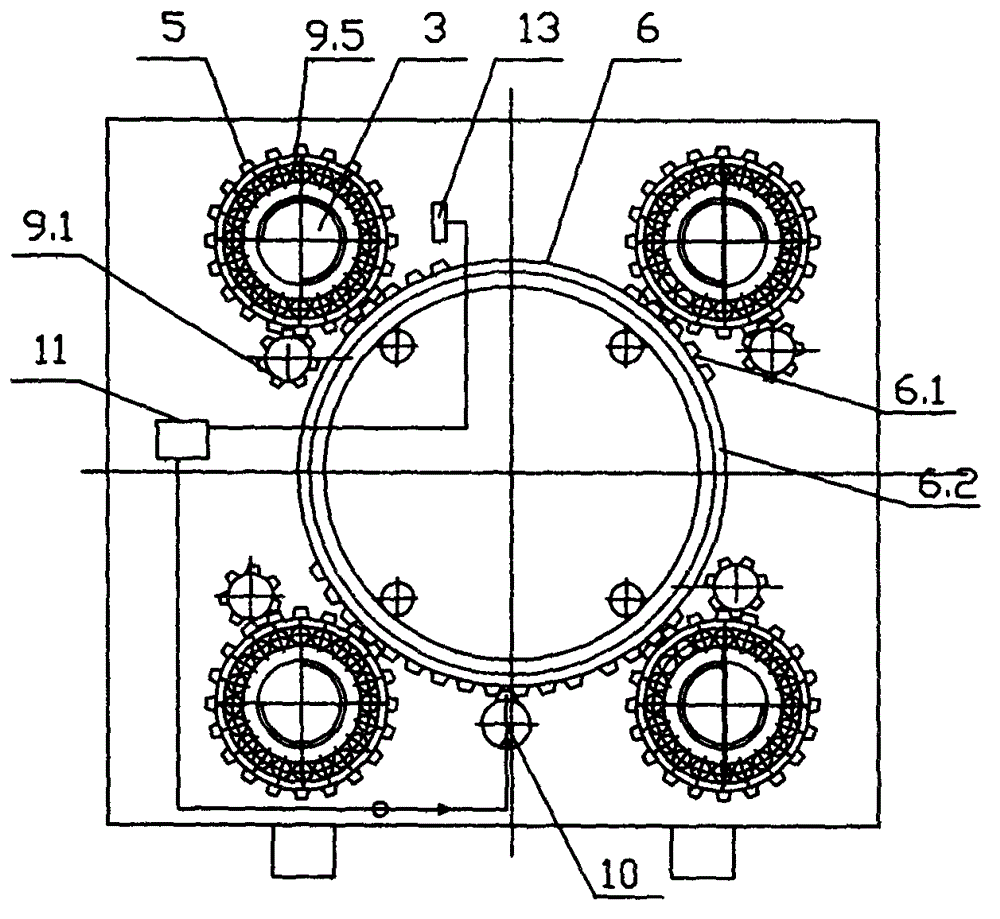

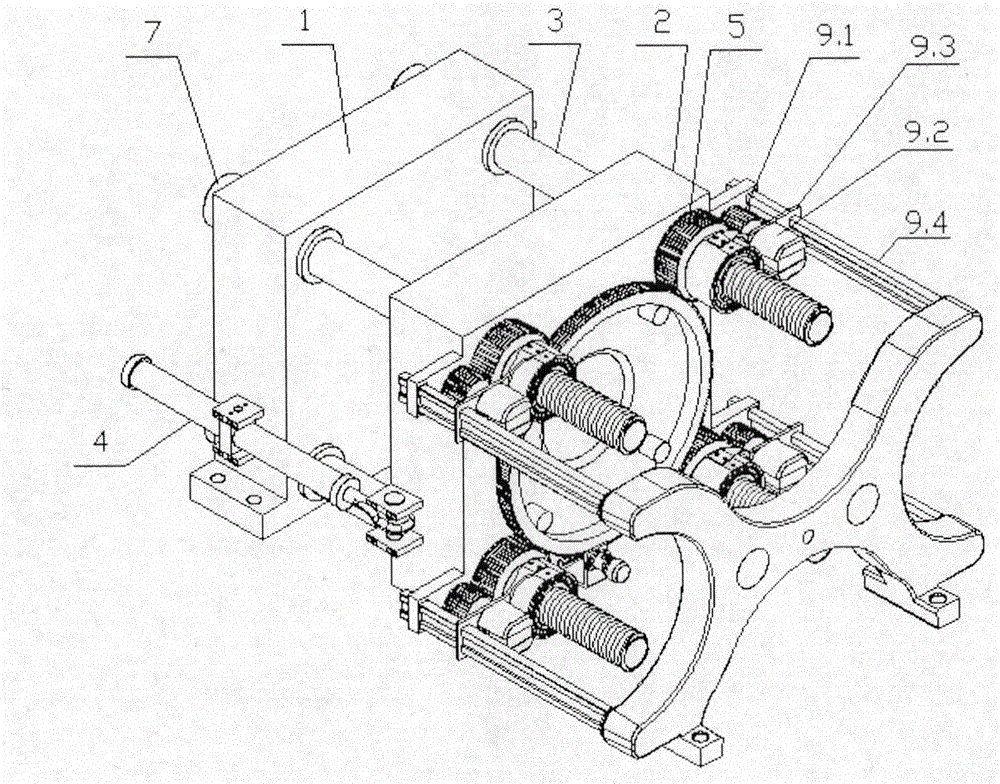

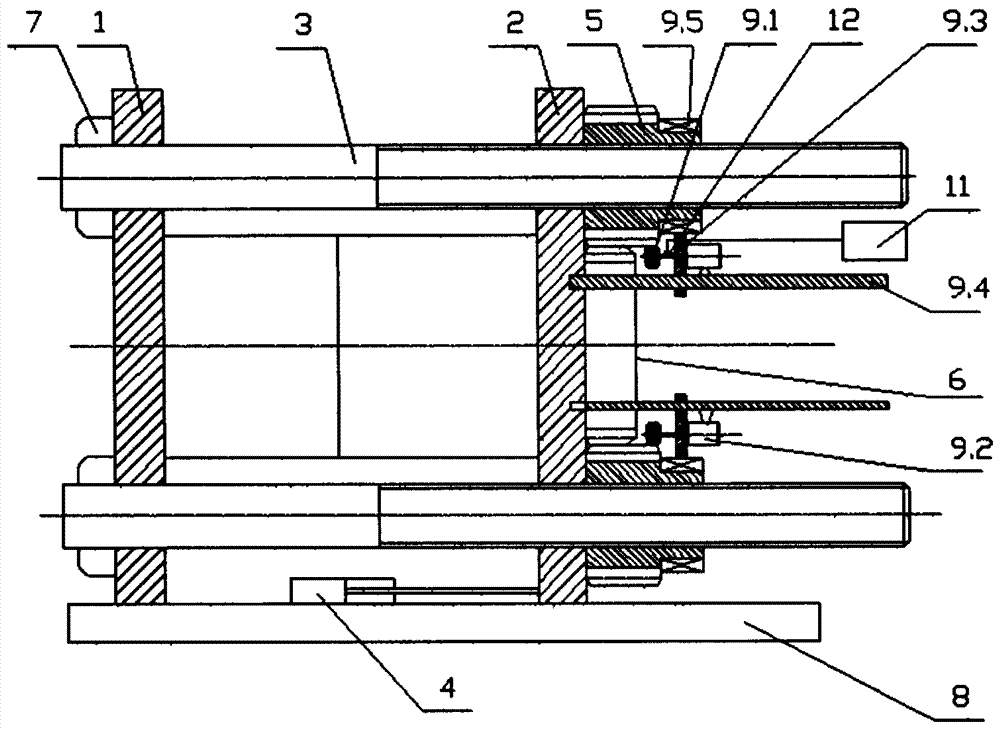

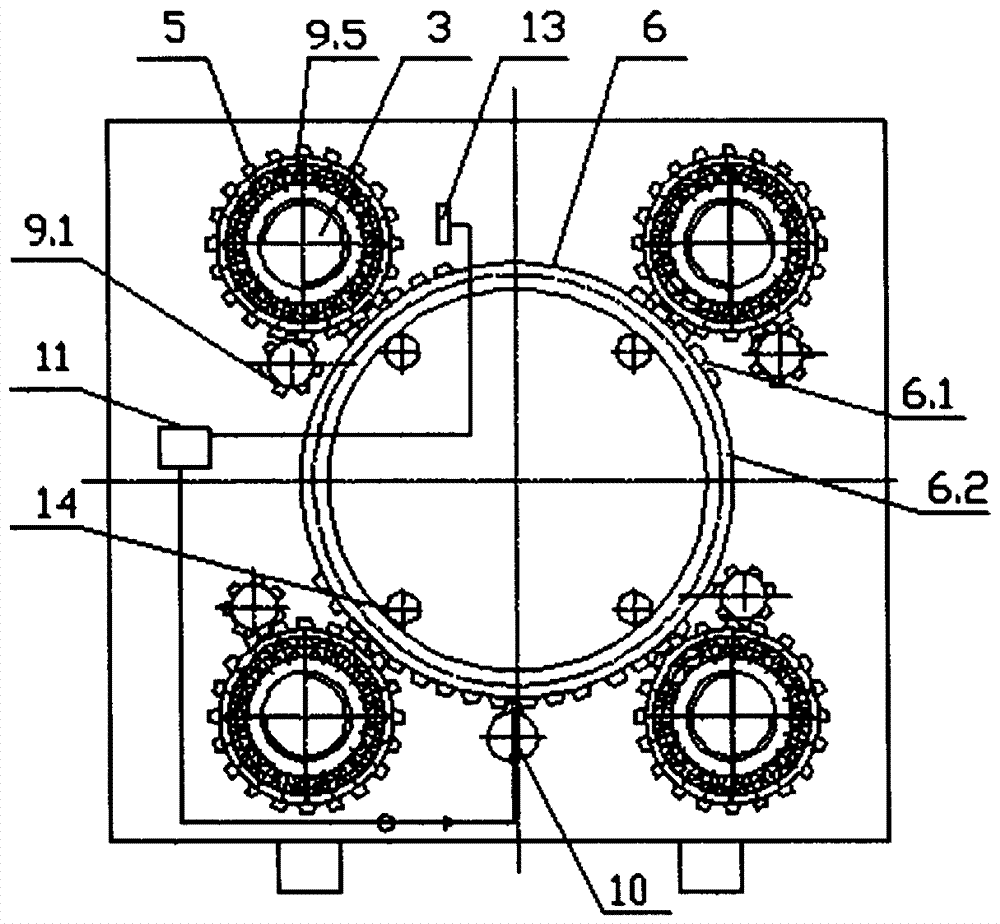

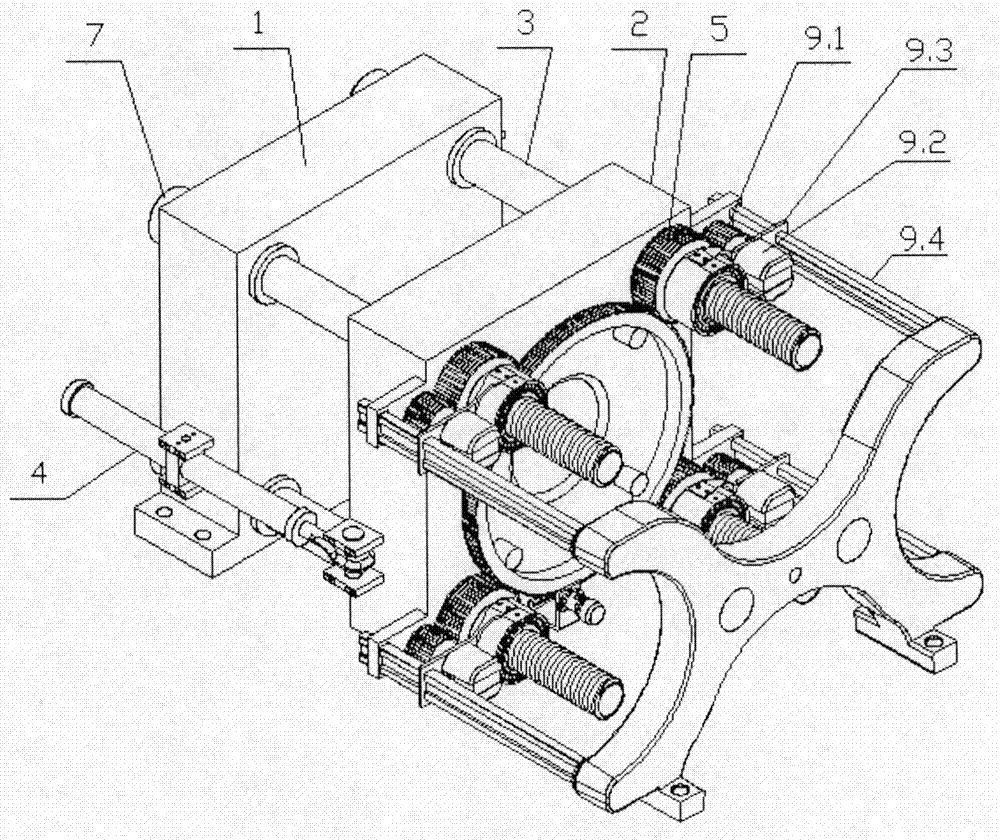

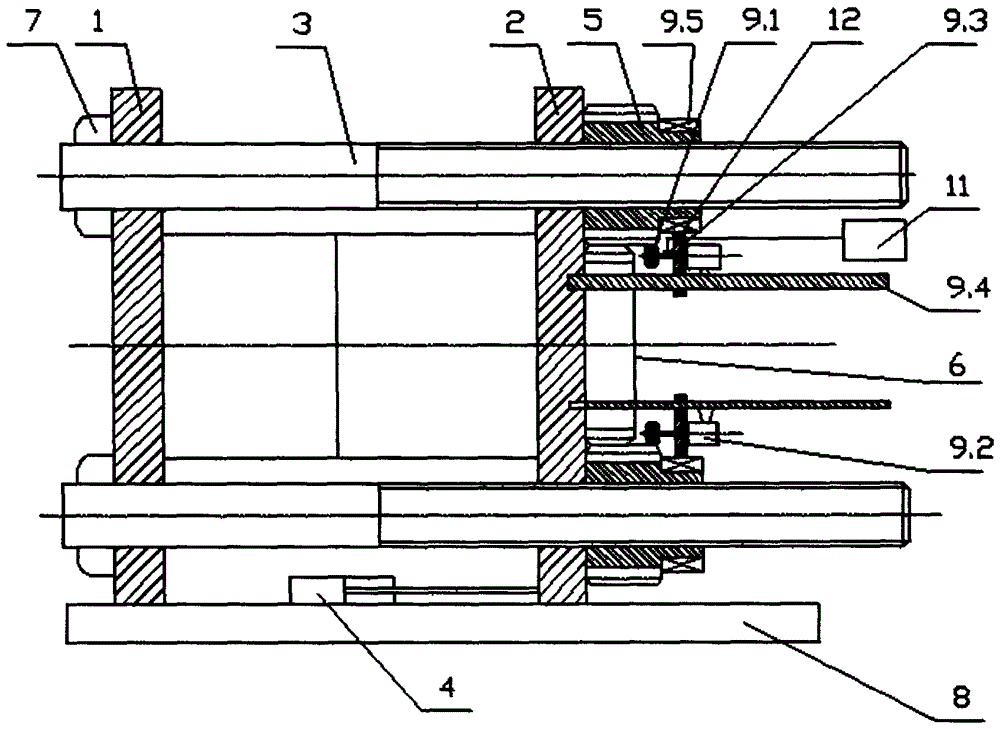

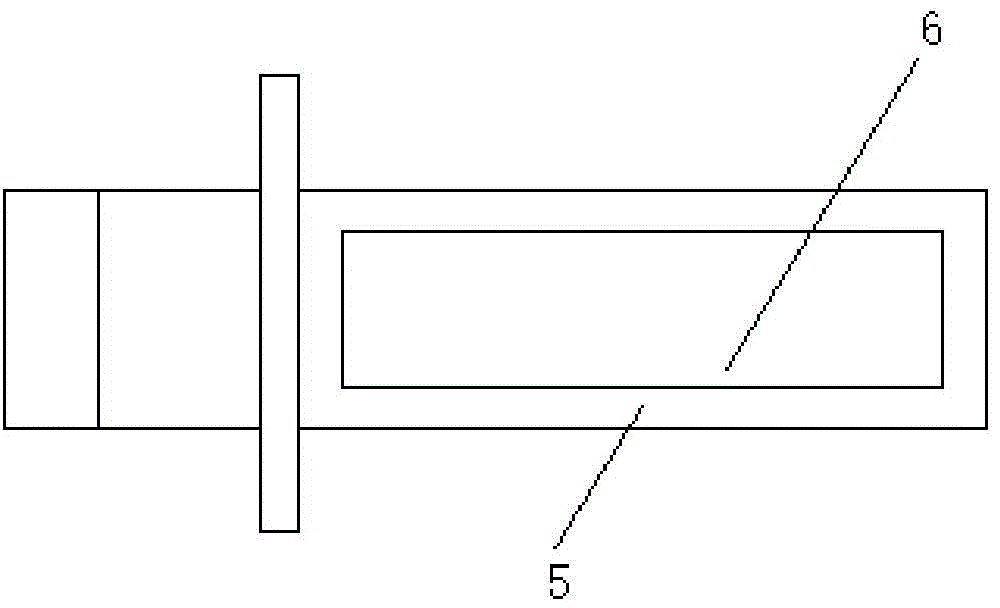

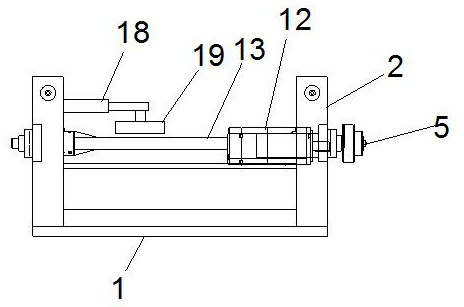

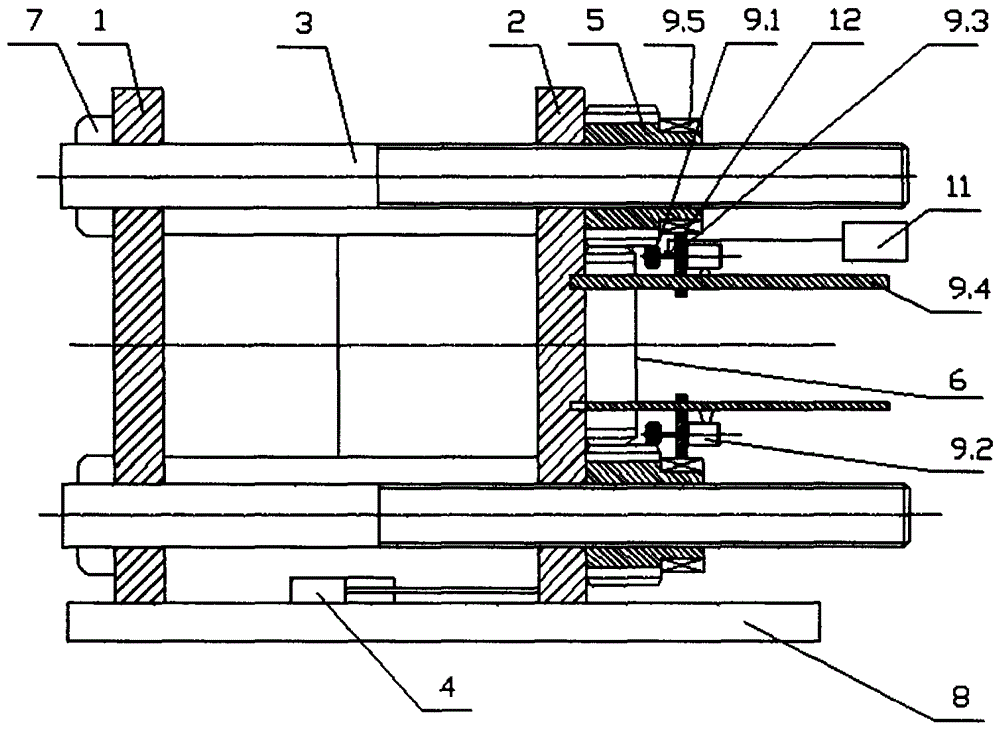

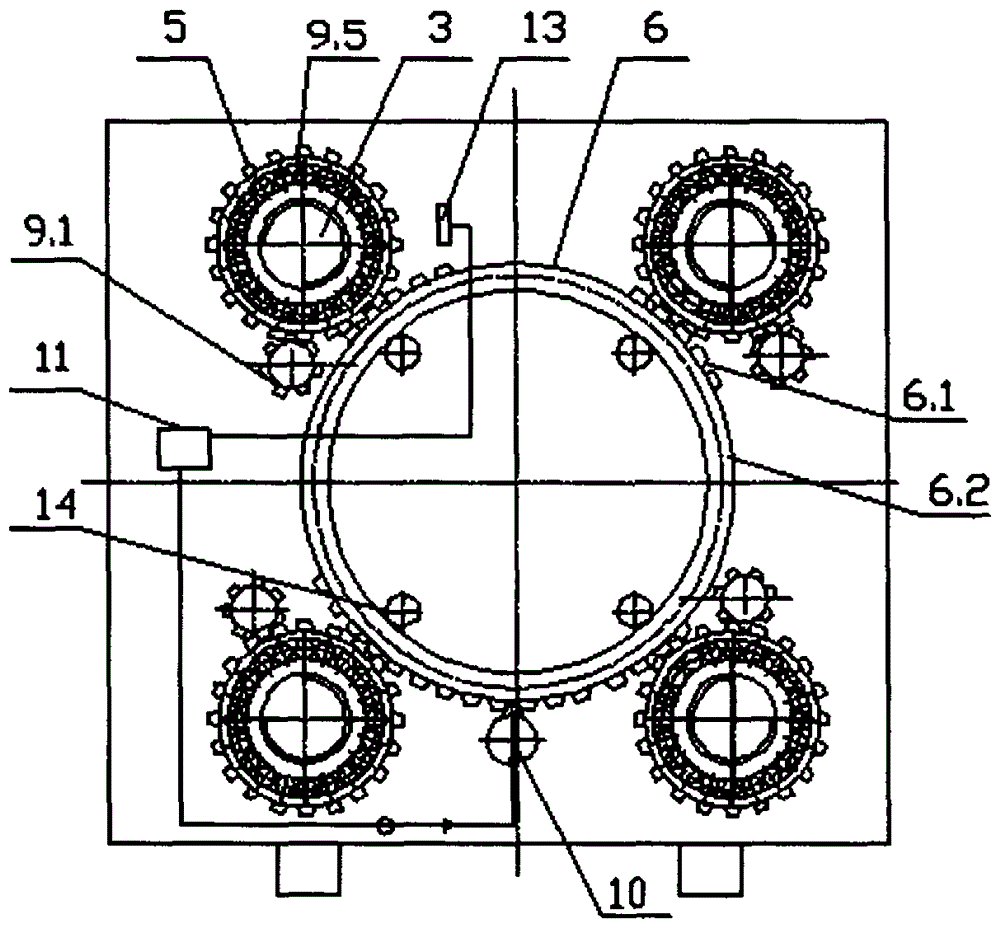

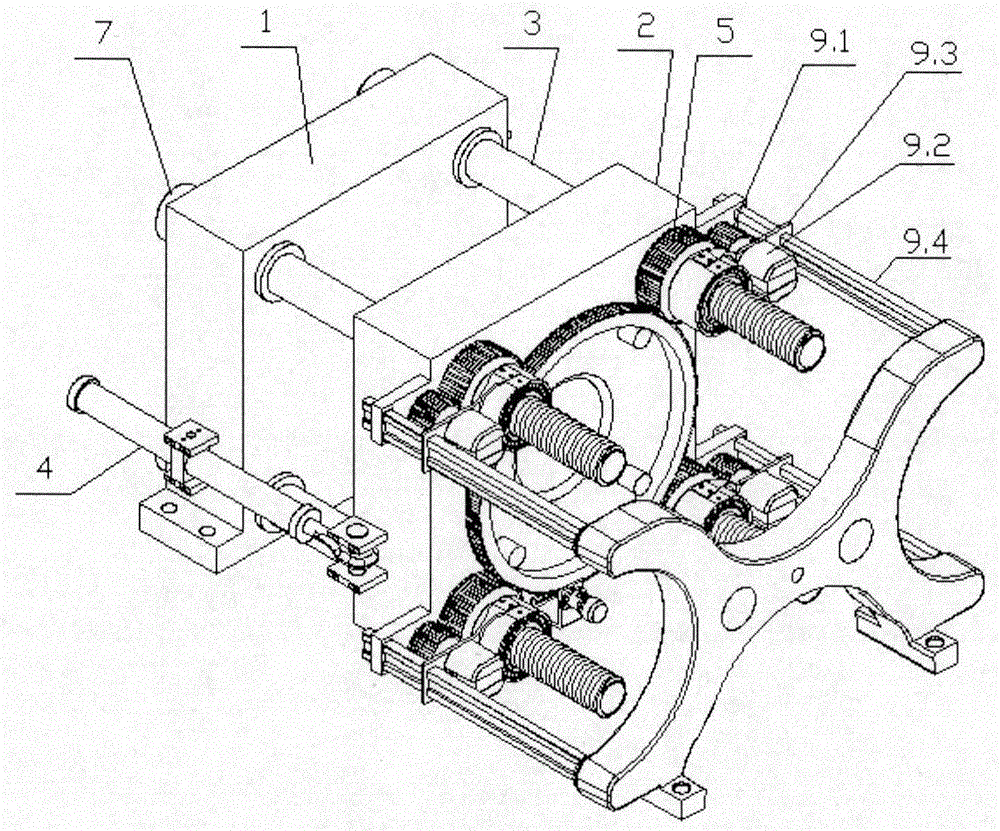

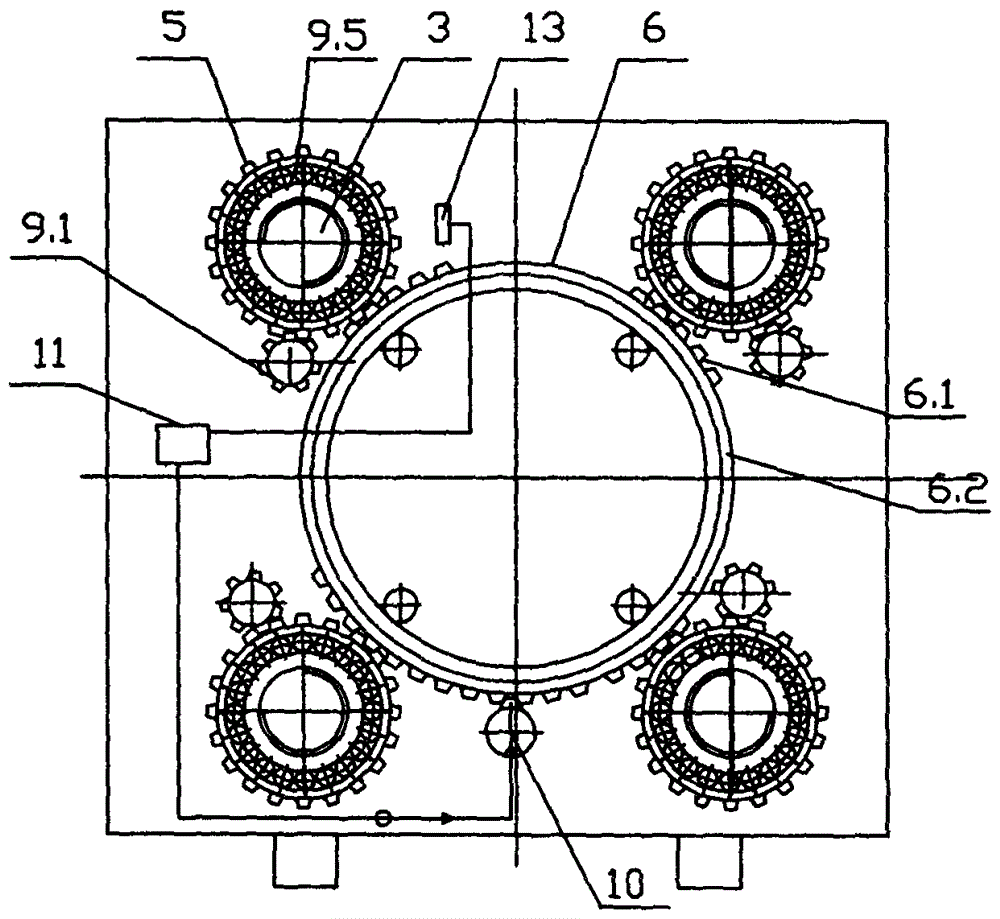

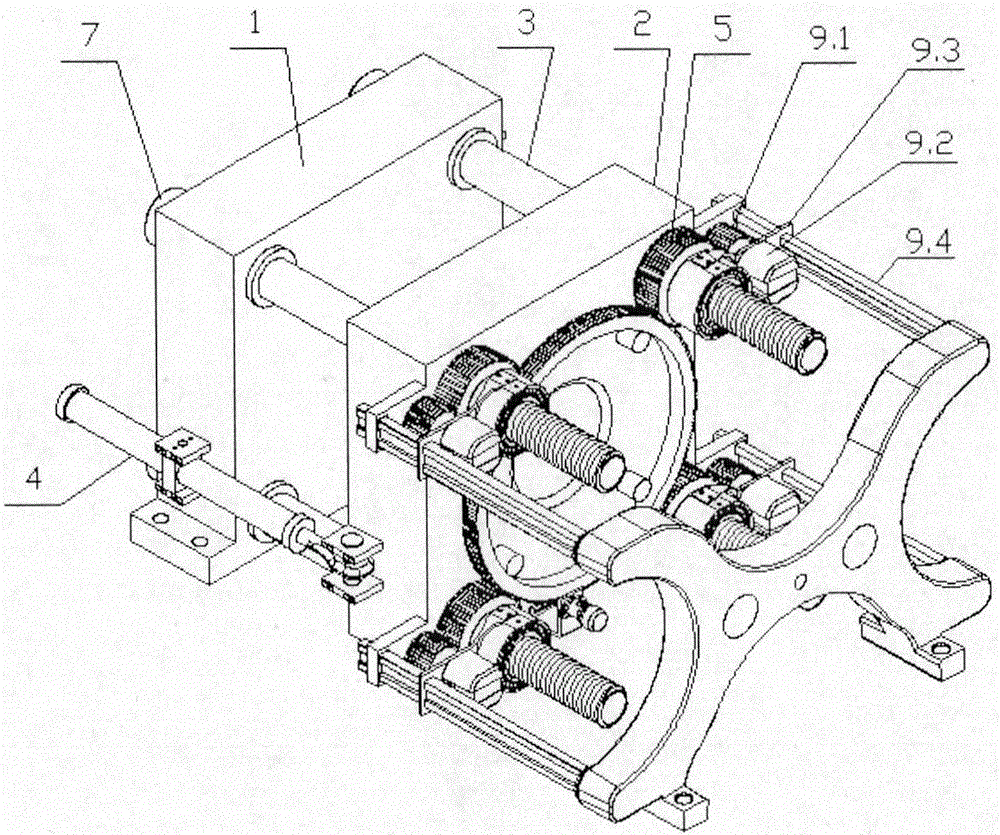

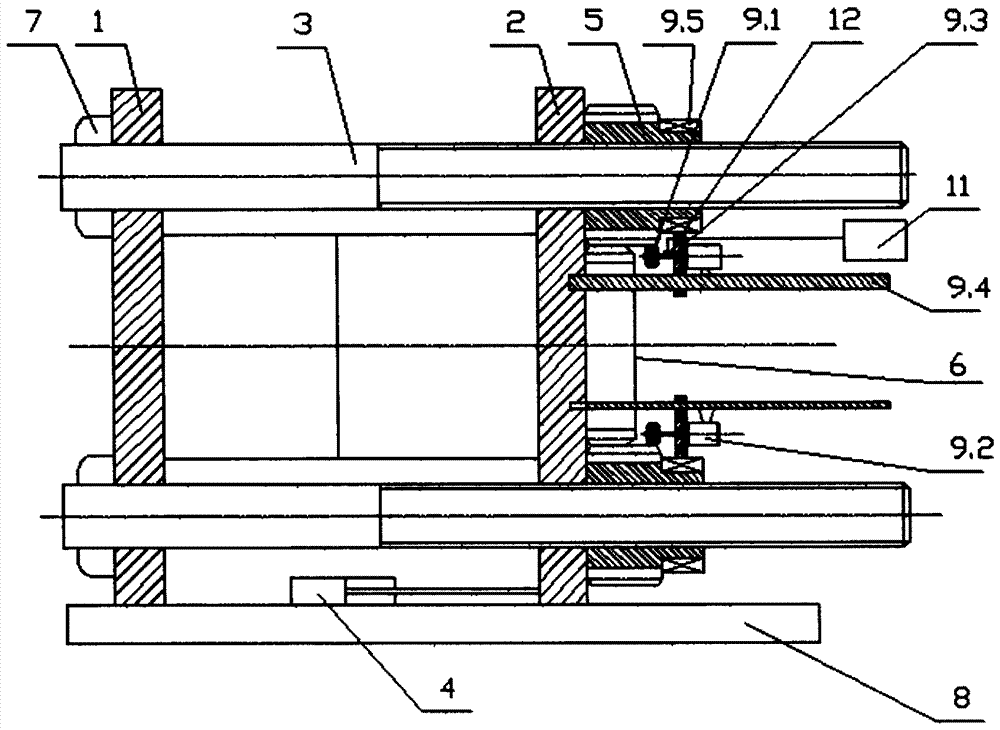

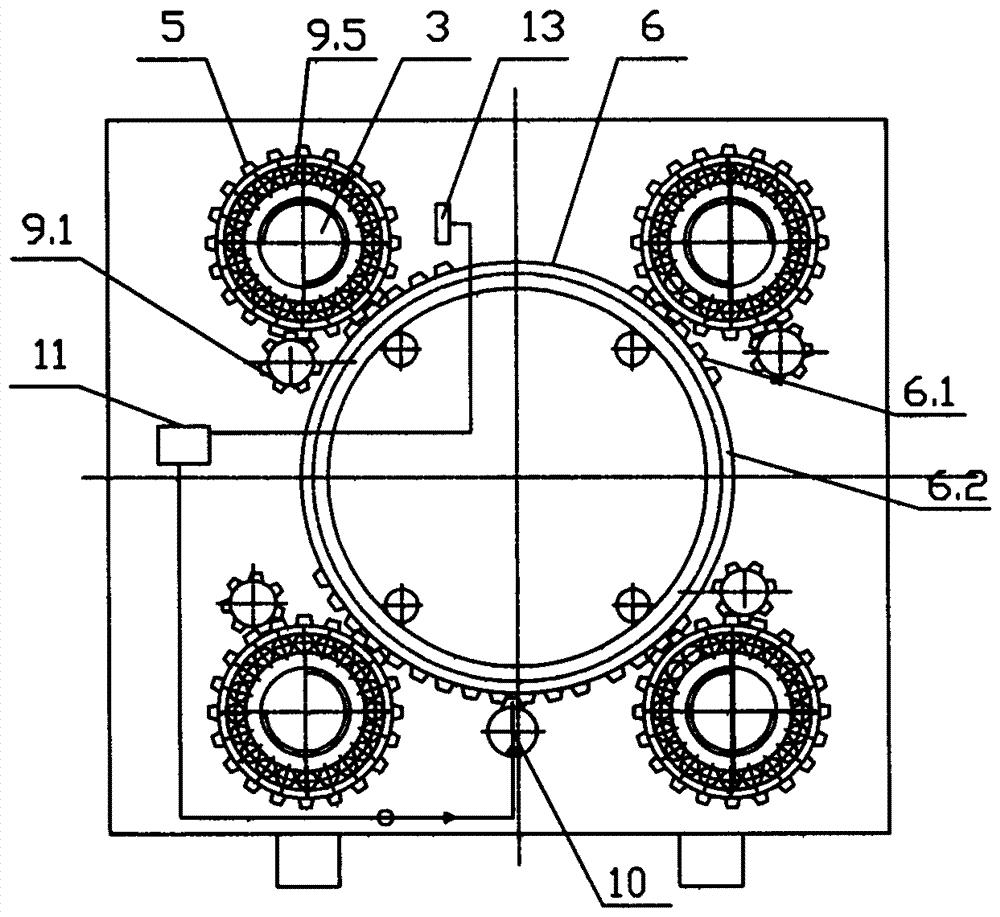

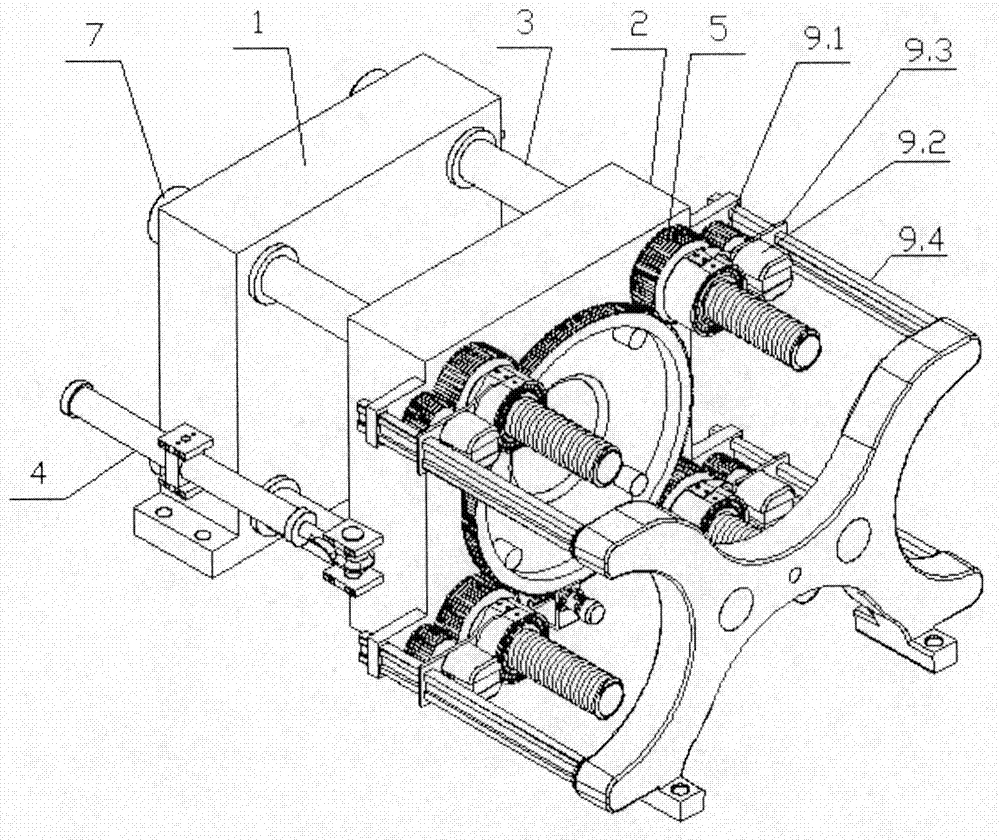

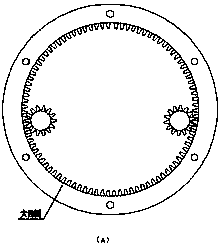

Self-locking clamping mechanism of injection molding machine

The inventiondiscloses a self-locking clamping mechanism of an injection molding machine. The self-locking clamping mechanism comprises a fixed mold plate (1), a movable mold plate (2), pull rods (3) and a mold moving oil cylinder (4), wherein the fixed mold plate (1) is fixed to one end of the pull rods (3), the movable mold plate (2) is arranged at the other end of the pull rods (3) in a sleeving manner, and a piston end of the mold moving oil cylinder (4) is connected with the movable mold plate (2) to drive the movable mold plate (2) to move. The clamping mechanism further comprises a mold locking structure, wherein the mold locking structure comprises rear nuts (5) corresponding to the pull rods (3) in a one-to-one mode, a large gear ring (6) and a power mechanism for driving the large gear ring (6) to rotate, the rear nuts (5) are screwed onto the pull rods (3), the outer edge of each rear nut (5) is in a gear shape, and the large gear ring is meshed with the rear nuts (5) respectively under the drive of the power mechanism and drives the rear nuts to rotate on the corresponding pull rods. The self-locking clamping mechanism does not need a mold locking oil cylinder and reduces the energy consumption of mold locking through self-locking between mechanisms.

Owner:CHINA JILIANG UNIV

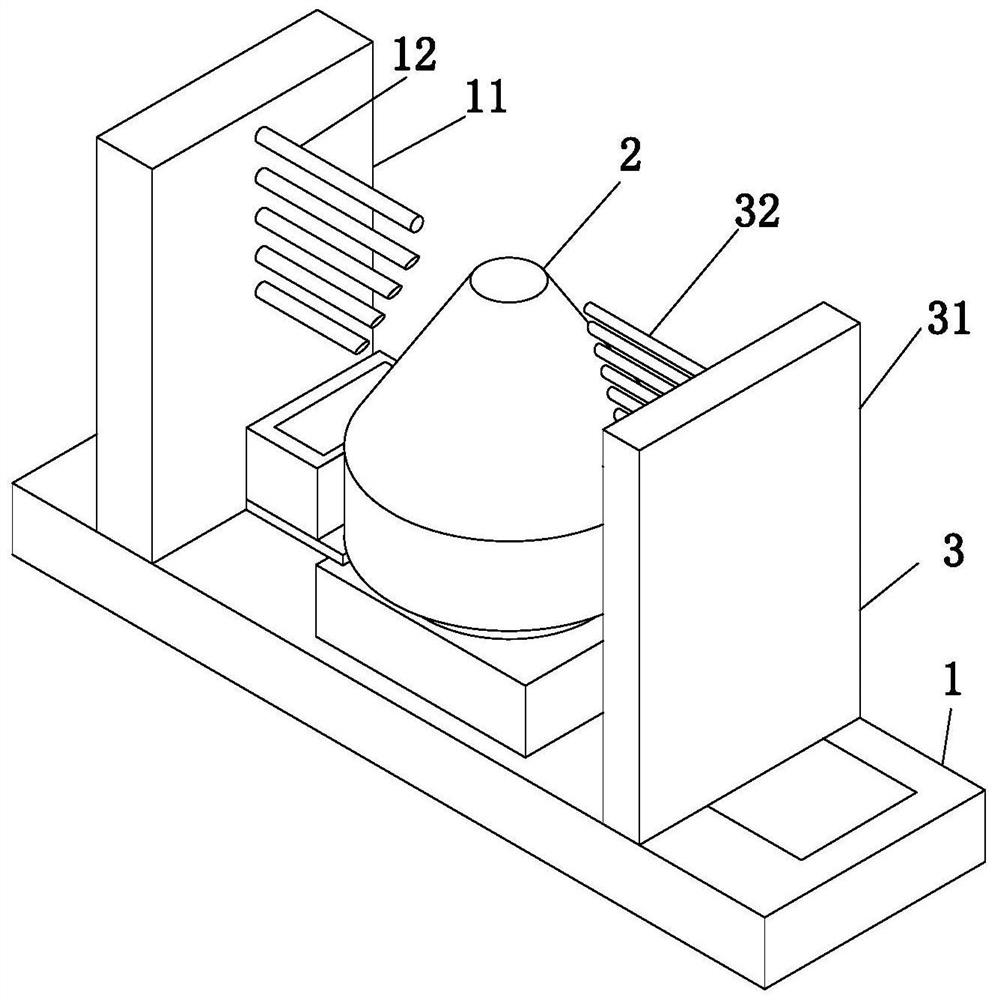

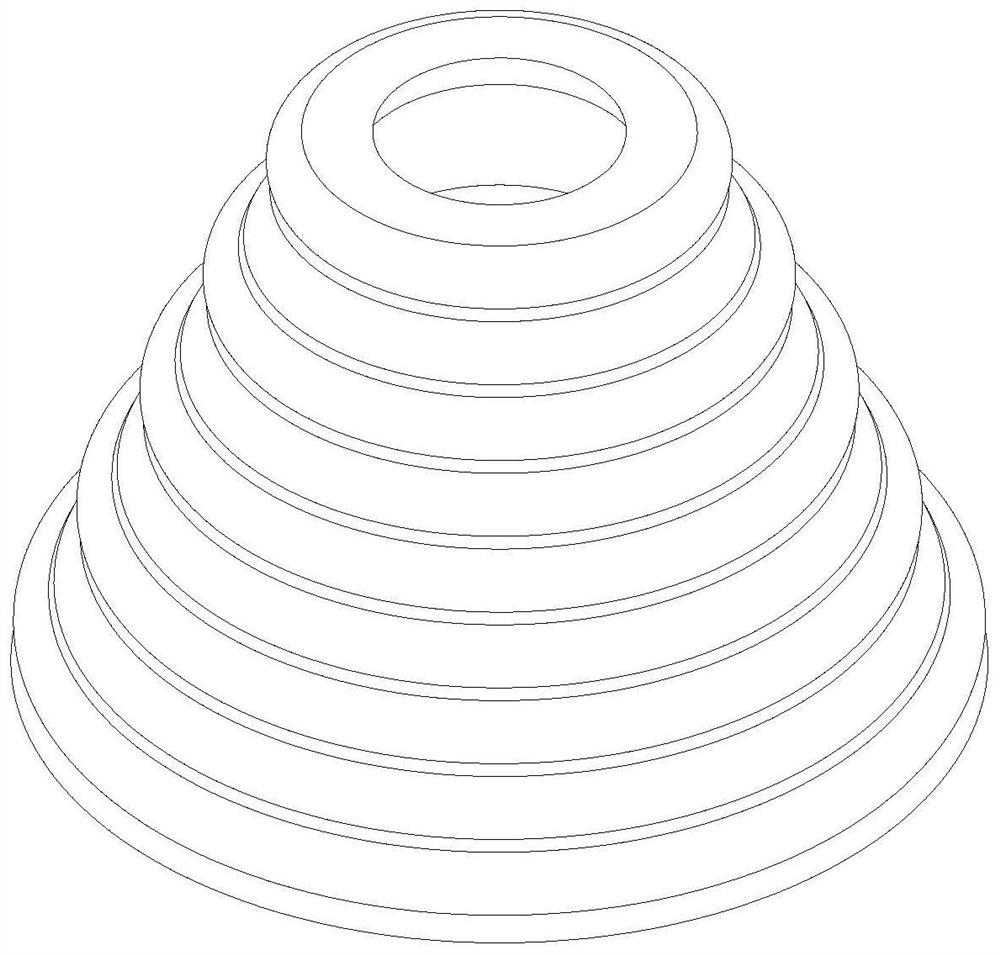

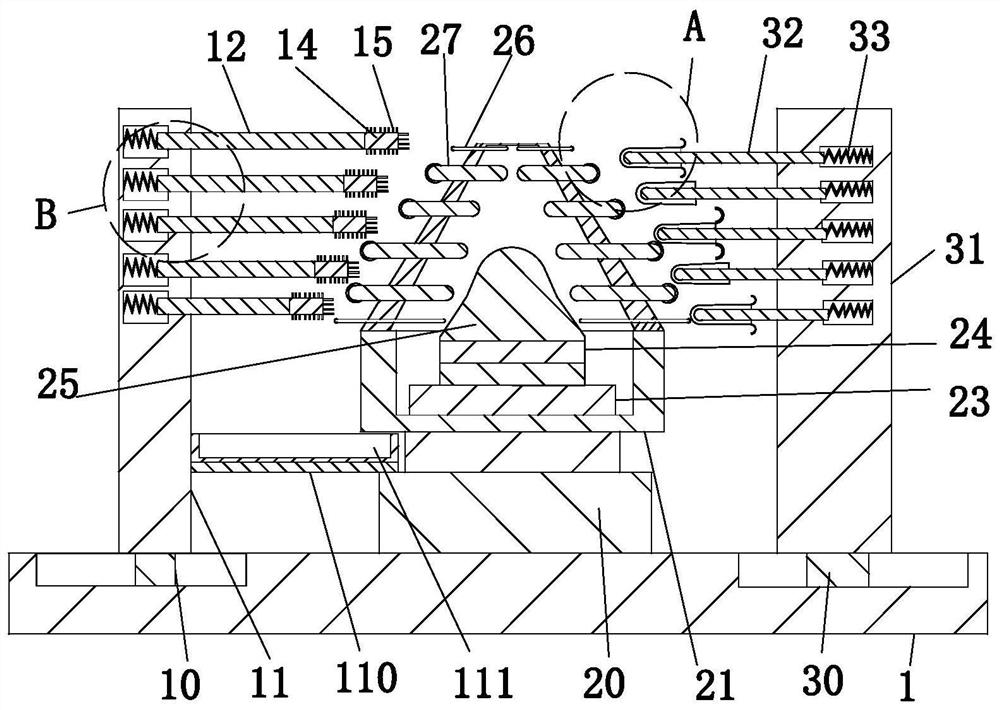

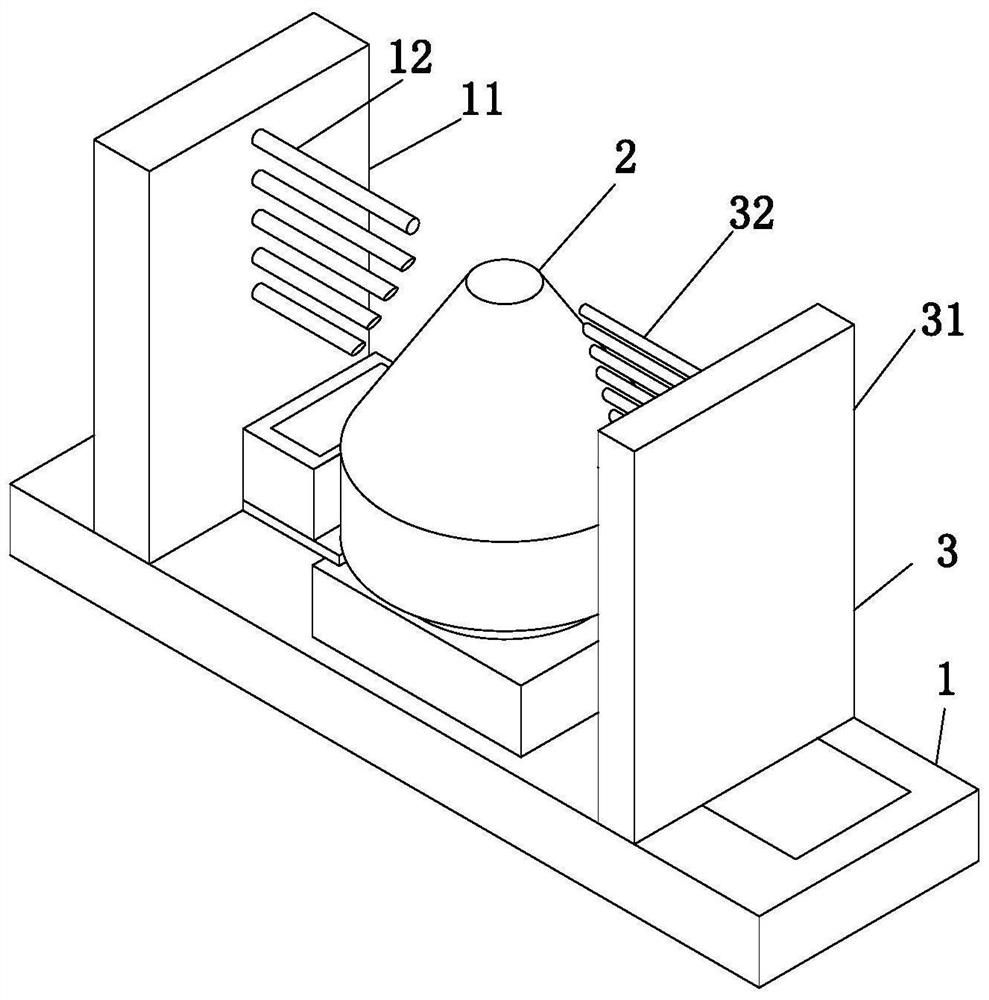

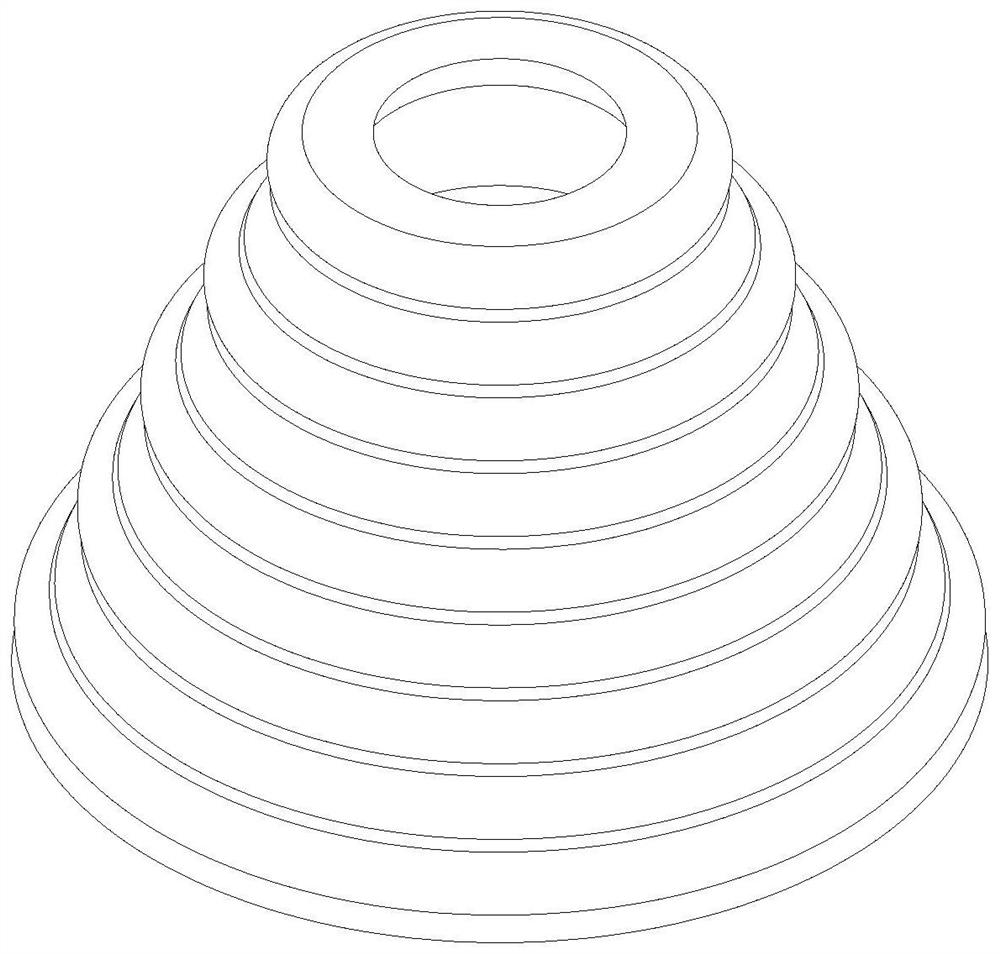

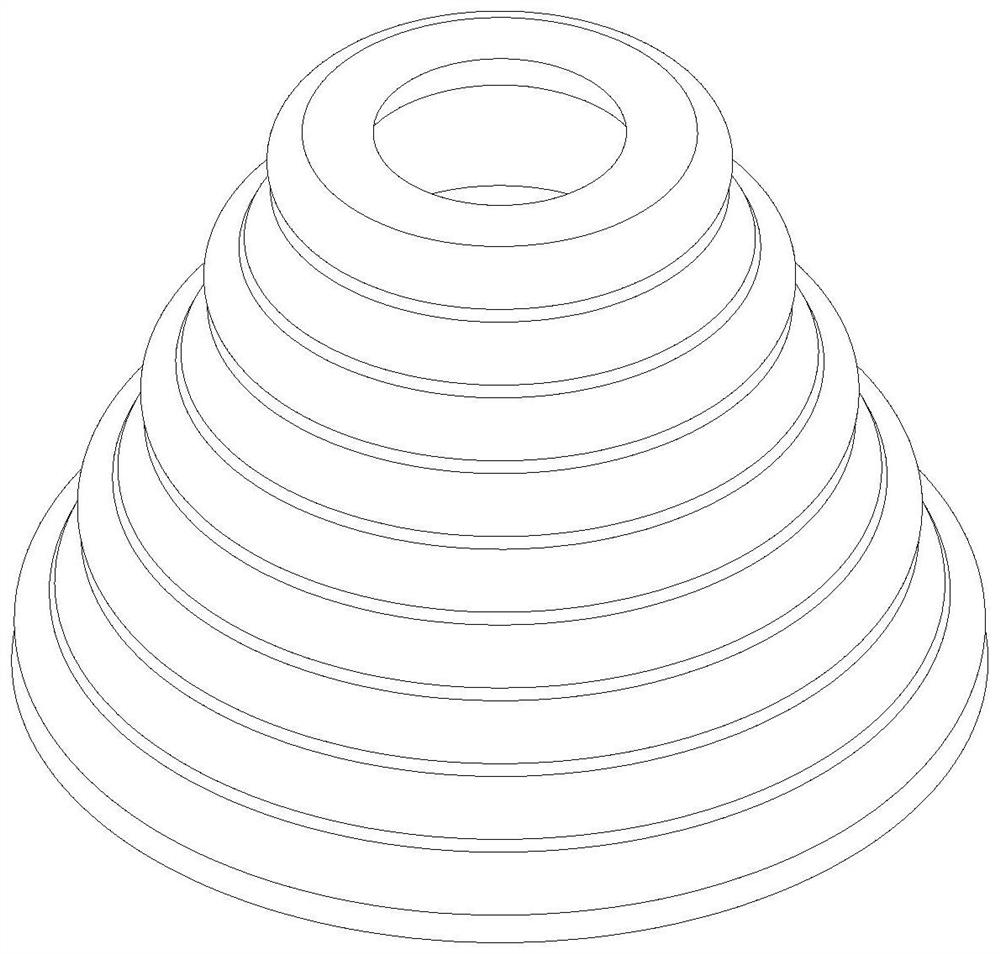

Automobile plastic part manufacturing and finishing machine

InactiveCN112091770AAvoid messPrevent disengagementEdge grinding machinesGrinding carriagesWorkbenchGrinding process

The invention relates to an automobile plastic part manufacturing and finishing machine. The automobile plastic part manufacturing and finishing machine comprises a workbench, a clamping mechanism anda grinding mechanism; the clamping mechanism is installed in the middle of the upper end face of the workbench, and the grinding mechanism is arranged on the right side of the clamping mechanism. According to the automobile plastic part manufacturing and finishing machine, the clamping mechanism is used for clamping the interior of an automobile plastic part, the clamping mechanism is clamped into an internal thread groove of the automobile plastic part and used for correspondingly clamping the threaded groove inside the automobile plastic part, the automobile plastic part is prevented from being disengaged from the workbench in the rotating grinding process, and the grinding mechanism is adopted for grinding the surface of the automobile plastic part; and a grinding rod stretches out anddraws back according to the surface shape of the automobile plastic part, so that the grinding rod is completely attached to the outer surface of the automobile plastic part, rubber layers are installed on the left end faces of fixing rods and clamping rods, and the phenomenon that when the fixing rods and the clamping rods clamp the automobile plastic part, the automobile plastic part is clampedand damaged is avoided.

Owner:深圳市弈燃科技有限公司

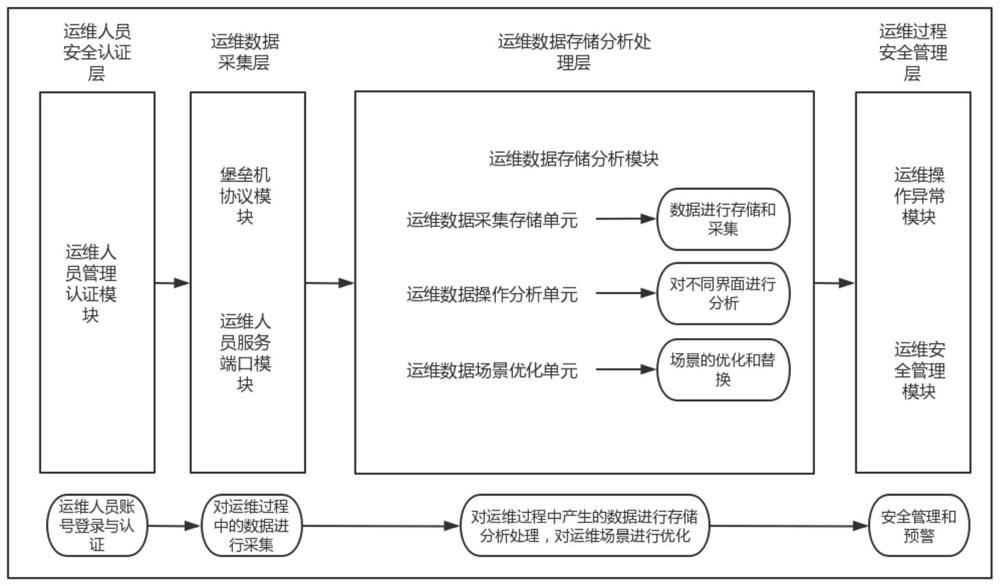

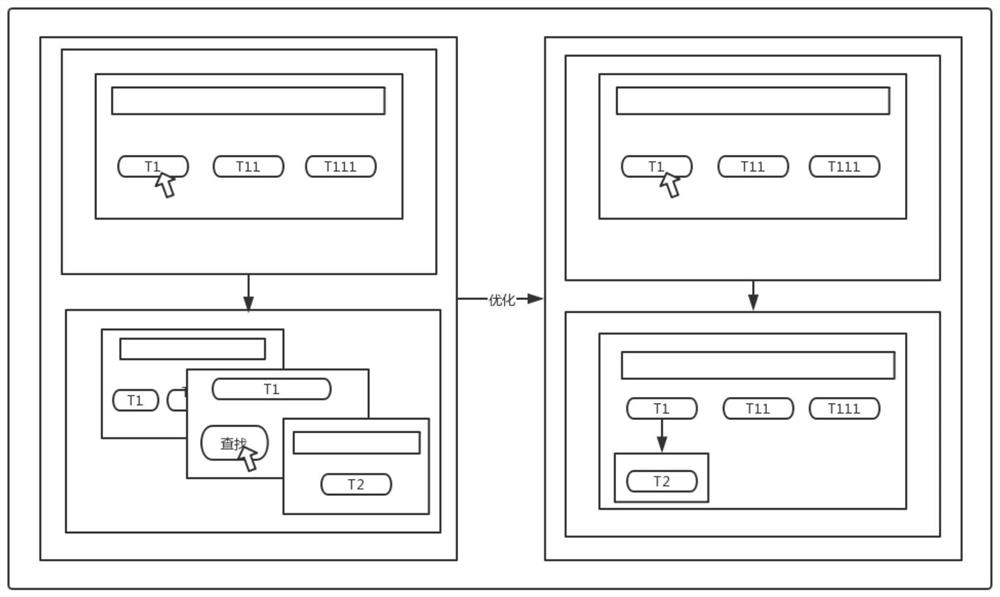

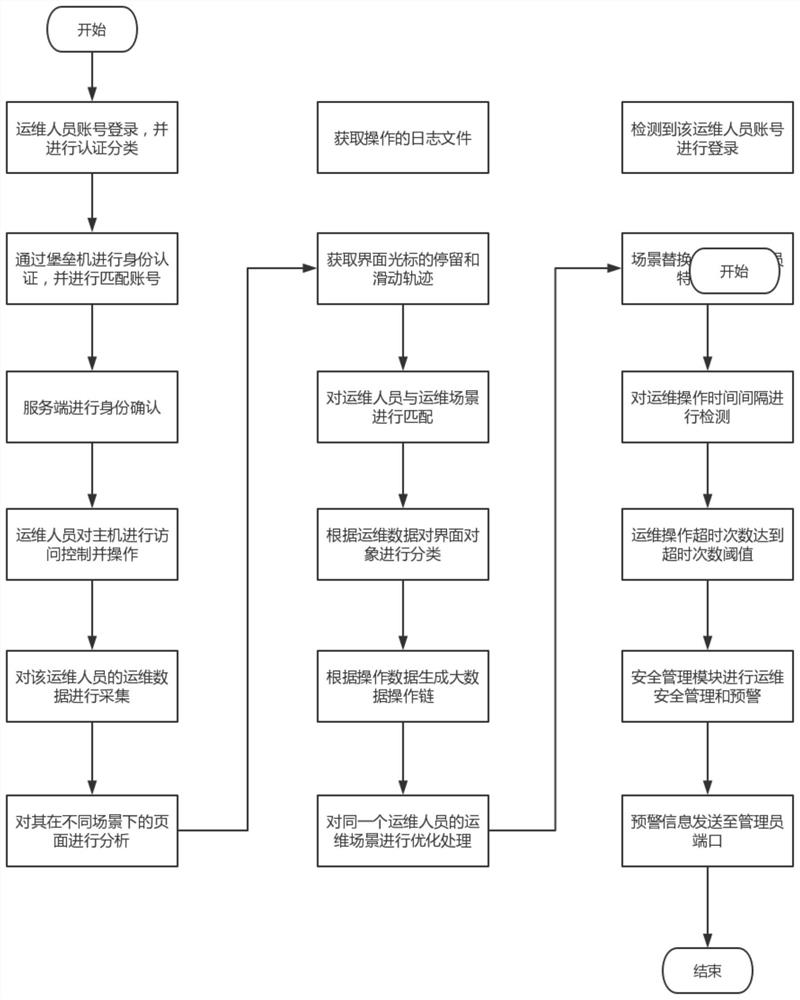

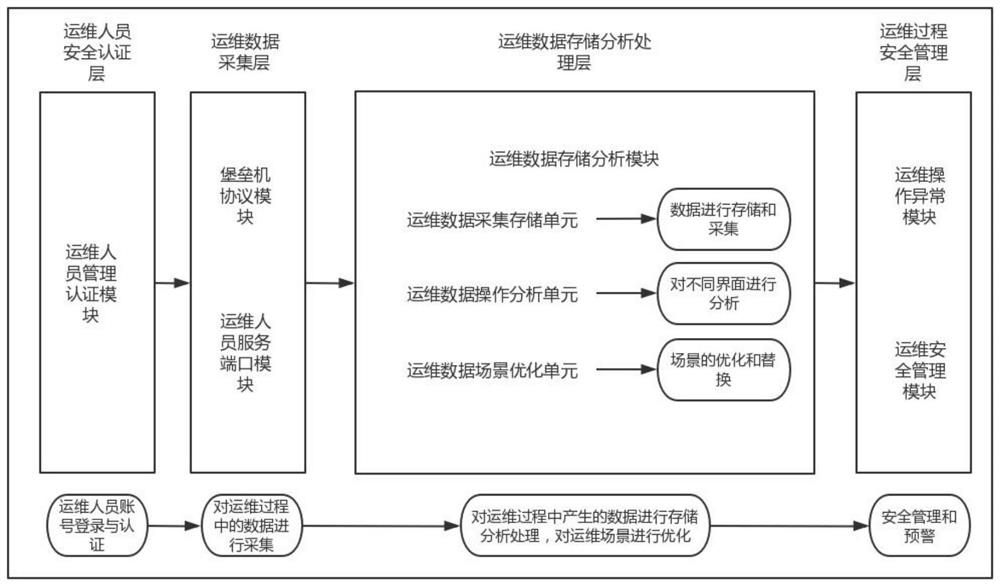

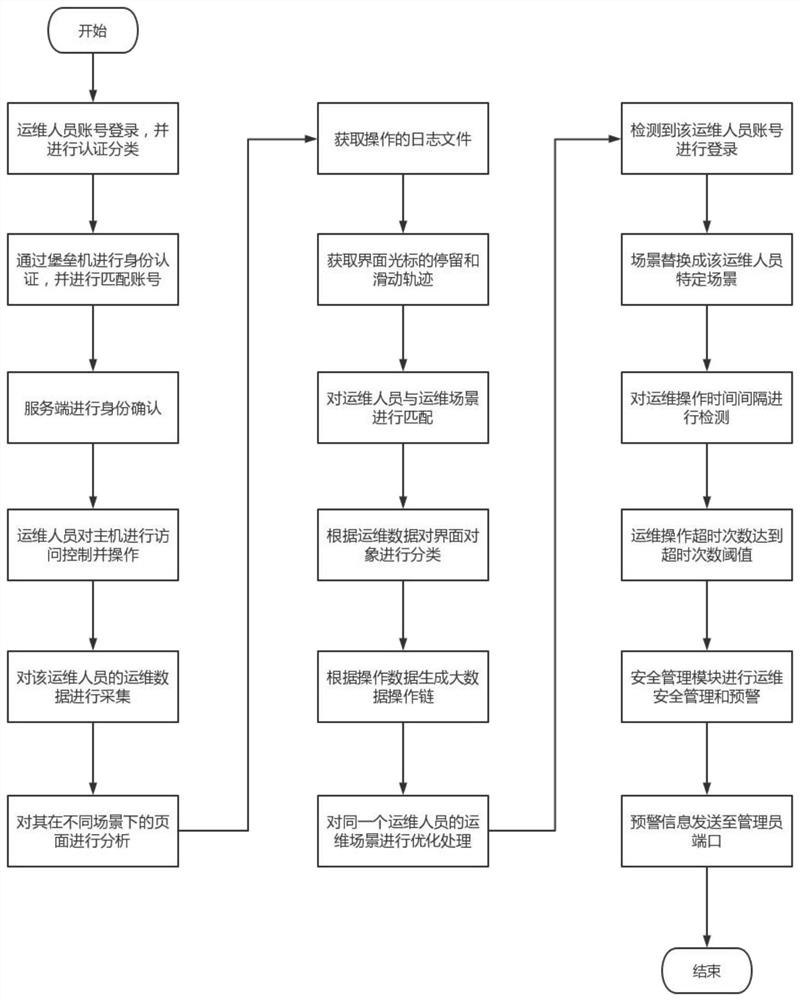

Network security operation and maintenance management system based on bastion host

ActiveCN113364758AAvoid inconvenienceEnsure safetyTransmissionData acquisitionMaintenance management

The invention discloses a network security operation and maintenance management system based on a bastion host, and belongs to the technical field of operation and maintenance management. The system comprises an operation and maintenance personnel security authentication layer, an operation and maintenance data acquisition layer, an operation and maintenance data storage, analysis and processing layer and an operation and maintenance process security management layer. The operation and maintenance personnel safety certification layer is used for carrying out safety certification login of operation and maintenance personnel; the operation and maintenance data acquisition layer is used for acquiring data in an operation and maintenance process; the operation and maintenance data storage, analysis and processing layer is used for storing, analyzing and processing data generated in an operation and maintenance process and optimizing an operation and maintenance scene; the operation and maintenance process safety management layer is used for monitoring and early warning abnormal behaviors occurring in the operation and maintenance process. According to the invention, the operation and maintenance scene can be optimized, the method is more suitable for the operation and maintenance operation of each operation and maintenance person, and safe operation and maintenance management can be carried out according to the change of the time interval in the operation and maintenance operation.

Owner:珠海市鸿瑞信息技术股份有限公司

Mold opening and closing method of self-locking type mold closing mechanism of injection molding machine

The invention discloses a mold opening and closing method of a self-locking type mold closing mechanism of an injection molding machine. The self-locking type mold closing mechanism comprises a front mold plate, a movable mold plate, pull rods and a mold transferring oil cylinder, wherein the front mold plate is fixed at one ends of the pull rods, the movable mold plate is arranged at the other ends of the pull rods in a sheathing manner, a piston rod of the mold transferring oil cylinder is connected with the movable mold plate to drive the movable mold plate to move; the self-locking type mold closing mechanism also comprises mold locking structures, wherein the mold locking structures comprise rear nuts corresponding to the pull rods one by one, large gear rings and power mechanisms for driving the corresponding large gear rings to rotate, the rear nuts are screwed on the corresponding pull rods, the outer edge of each rear nut is designed to be a gear shape, and each large gear ring is meshed with the corresponding rear nut under the driving of the corresponding power mechanism and drives the corresponding rear nut to rotate on the corresponding pull rod. According to the mold opening and closing method of the self-locking type mold closing mechanism of the injection molding machine, a mold locking oil cylinder is not used, and the mold locking energy consumption can be reduced due to self locking of mechanisms.

Owner:饶宾期

Mold opening and closing method for self-locking type mold closing mechanism based on two-plate machine

The invention discloses a mold opening and closing method for a self-locking type mold closing mechanism based on a two-plate machine. The mold opening and closing method is based on the self-locking type mold closing mechanism, and the self-locking type mold closing mechanism comprises a fixed mold plate, a movable mold plate, pull rods and a mold moving oil cylinder, wherein the fixed mold plate is fixed at one ends of the pull rods, the other ends of the pull rods are sleeved by the movable mold plate, and a piston end of the mold moving oil cylinder is connected with the movable mold plate to drive the movable mold plate to move; and the mold closing mechanism further comprises a mold locking structure, the mold locking structure comprises rear screw nuts which are in one-to-one correspondence with the pull rods, a large gear ring and a power mechanism for driving the large gear ring to rotate, the rear screw nuts are screwed on the pull rods, the outer edges of the rear screw nuts are set to be like gears, and the large gear ring is meshed with the rear screw nuts under the drive of the power mechanism and drives the rear screw nuts to rotate on the corresponding pull rods. According to the mold opening and closing method disclosed by the invention, a mold locking oil cylinder is not required, and energy consumption in mold locking is reduced by self-locking of the mechanism.

Owner:CHINA JILIANG UNIV

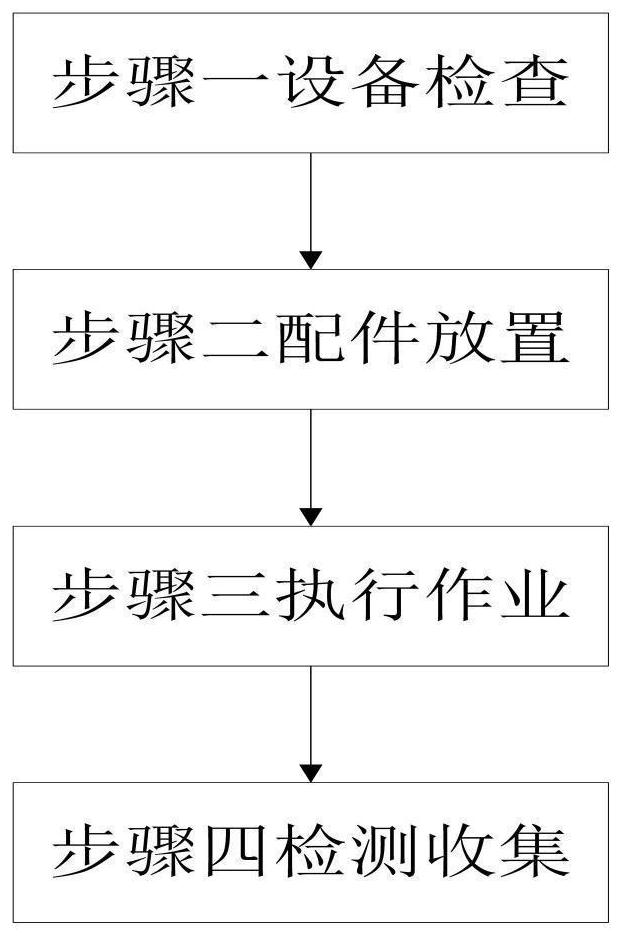

Automobile plastic part manufacturing method

ActiveCN112123093APrevent disengagementPrevent stuck and other phenomenaEdge grinding machinesGrinding drivesWorkbenchAutomotive engineering

The invention relates to an automobile plastic part manufacturing method which uses a finishing machine. The finishing machine comprises a workbench, a clamping mechanism and a grinding mechanism, theclamping mechanism is arranged in the middle of the upper end surface of the workbench, and the grinding mechanism is arranged on the right side of the clamping mechanism. The clamping mechanism is adopted for clamping the interior of an automobile plastic part, the clamping mechanism is clamped into an internal thread groove of the automobile plastic part for corresponding clamping-in of the internal thread groove of the automobile plastic part, and the automobile plastic part is prevented from being disengaged from the workbench in the rotating polishing process; and the grinding mechanismis adopted to grind the surface of the automobile plastic part,grinding rods stretch out and draw back according to the surface shape of the automobile plastic part, so that the grinding rods are completely attached to the outer surface of the automobile plastic part, rubber layers are installed on the left end faces of fixing rods and the left end faces of clamping rods. and the phenomenon that the fixing rods and the clamping rods cause clamping damage to the automobile plastic part when clamping the automobile plastic part is prevented.

Owner:柳州精特汽配制造有限公司

Mold opening and closing method of self-locking two-plate machine mold closing mechanism

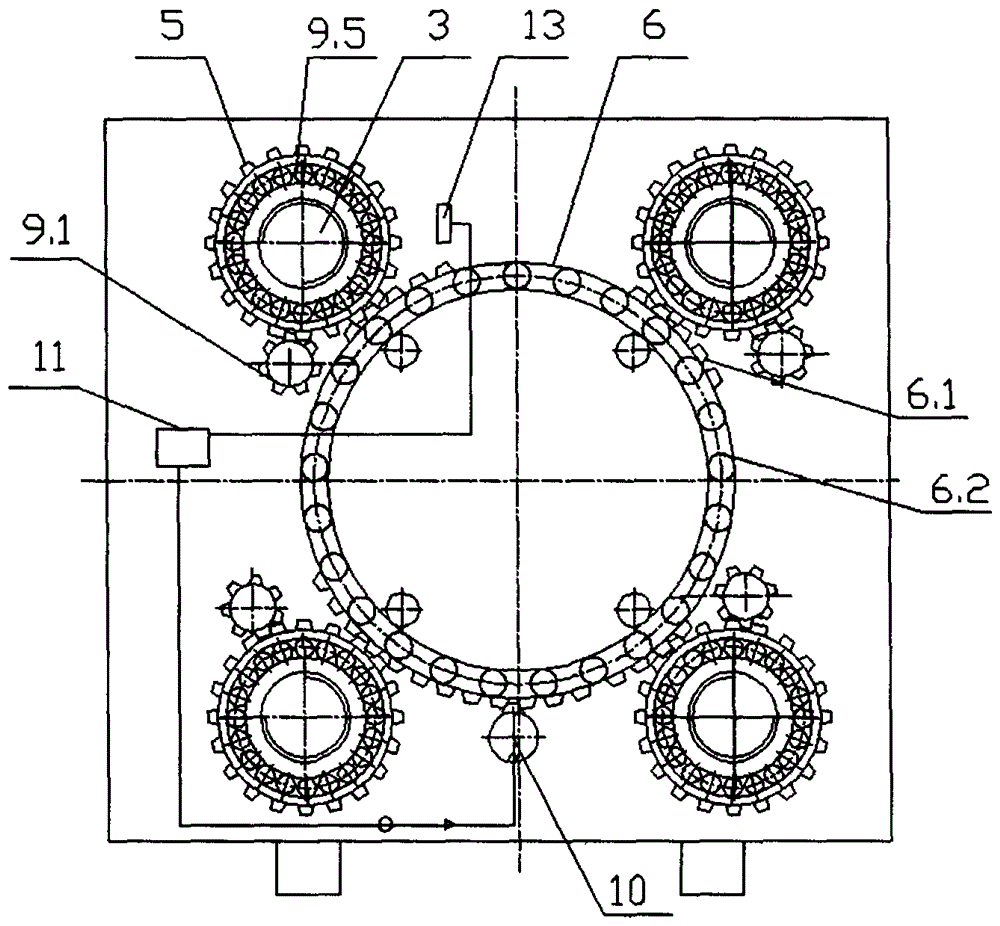

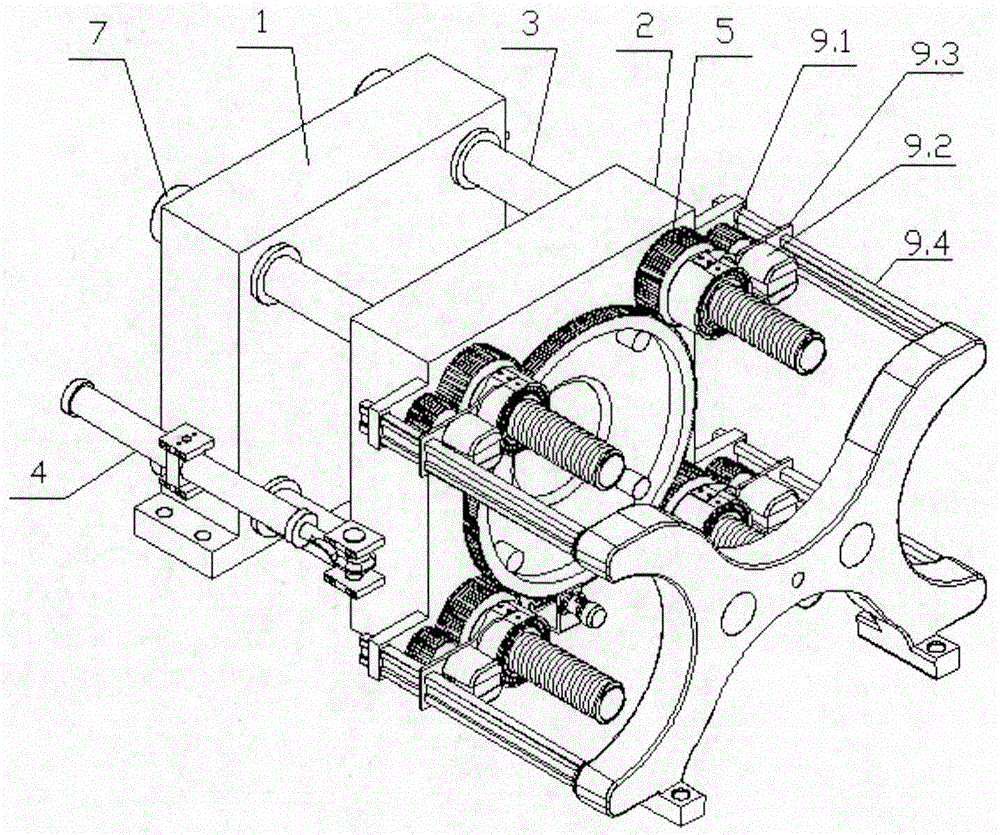

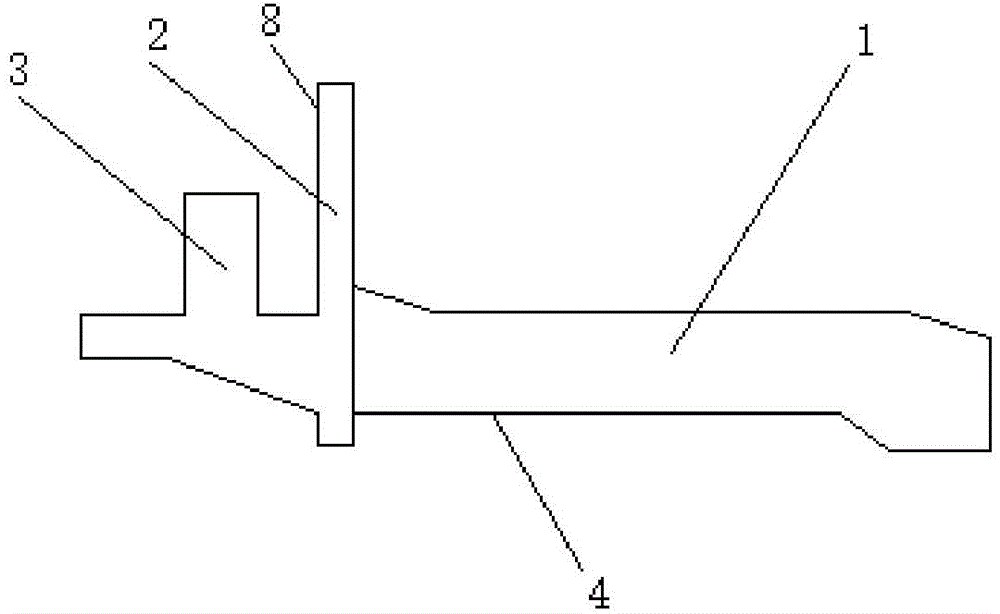

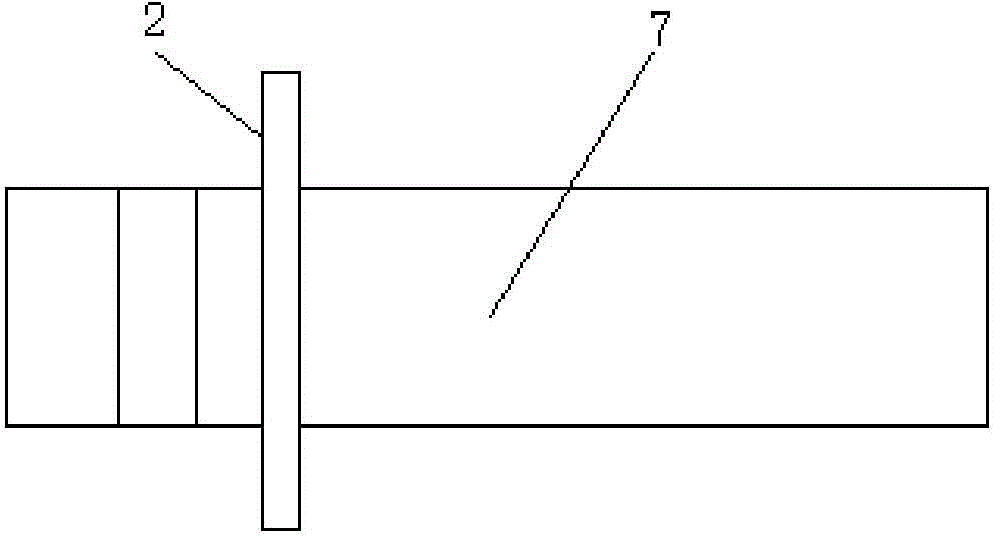

The invention discloses a mold opening and closing method of a self-locking two-plate machine mold closing mechanism, which is based on the self-locking two-plate machine mold closing mechanism. The self-locking two-plate machine mold closing mechanism comprises a fixed mold plate (1), a moving mold plate (2), pull rods (3), a mold movement oil cylinder (4) and a mold locking structure, wherein the fixed mold plate (1) is fixed at one end of each pull rod (3); the moving mold plate is arranged at the other end of each pull rod (3) in a sleeving manner; a piston end of the mold movement oil cylinder (4) is connected with the moving mold plate (2); the mold locking structure comprises rear nuts (5), a big gear ring (6) and a power mechanism driving the big gear ring (6) to rotate; the rear nuts (5) are screwed on the pull rods (3); the outer edges of the rear nuts (5) are arranged into gear shapes; and the big gear ring is engaged with the rear nuts respectively, and drives the rear nuts to rotate on the corresponding pull rods. The method requires no mold locking oil cylinder, and reduces energy consumption of mold locking by utilizing self-locking between the mechanisms.

Owner:CHINA JILIANG UNIV

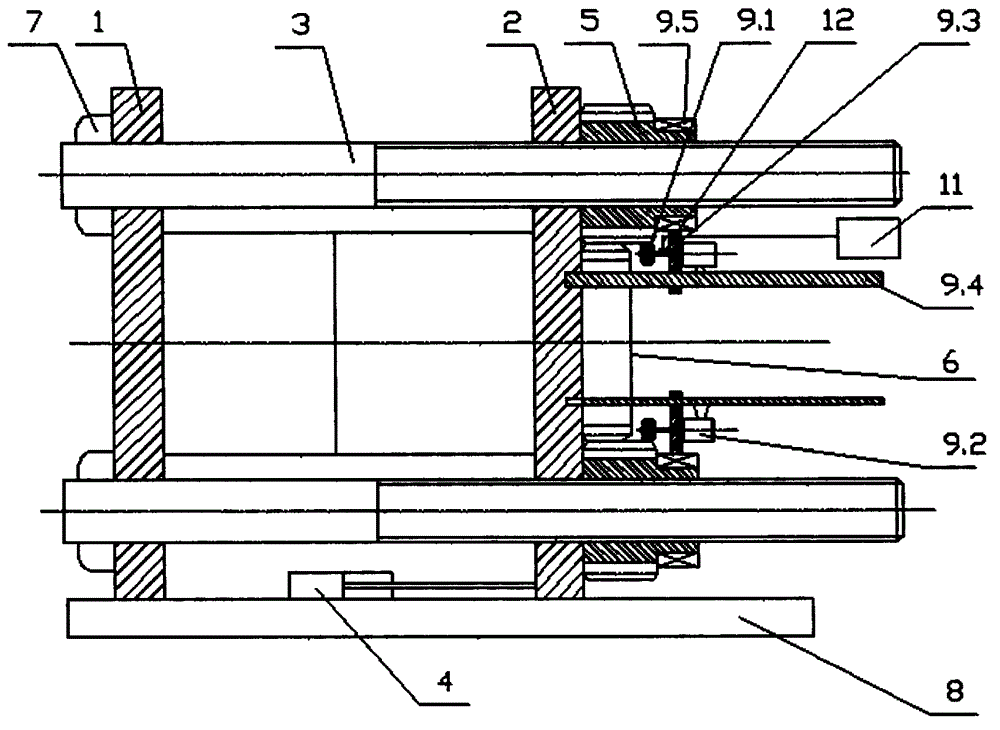

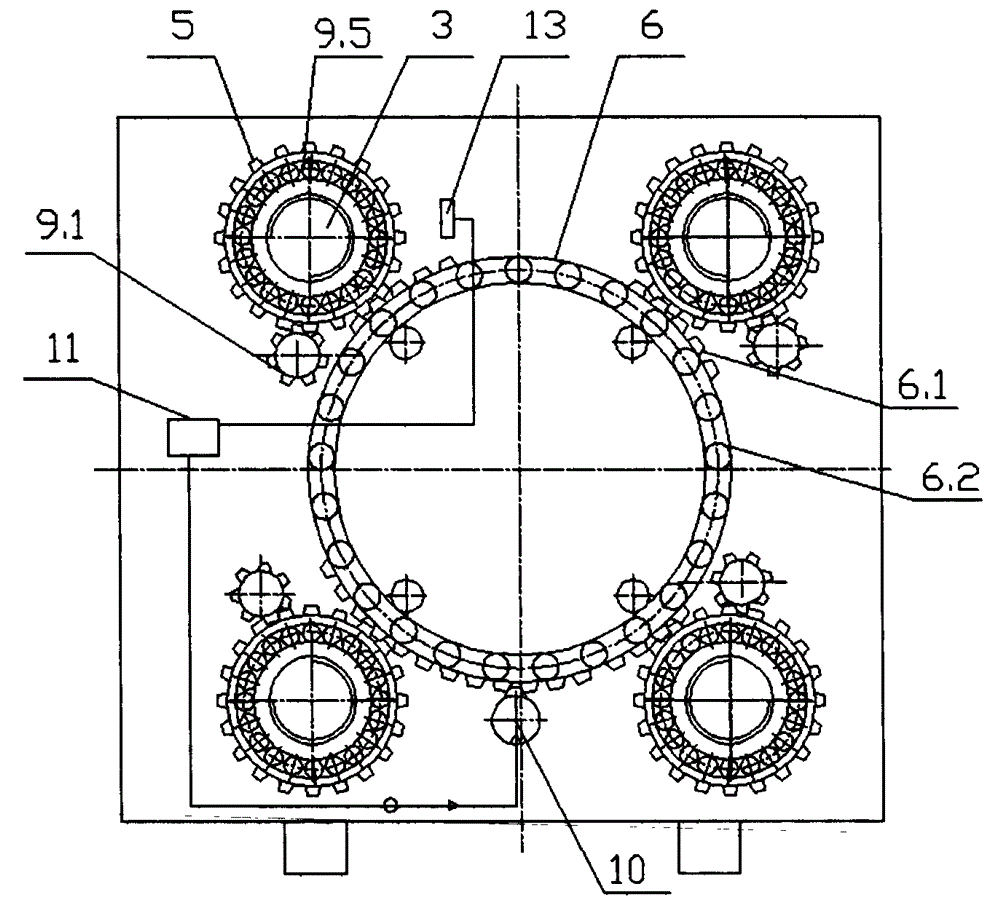

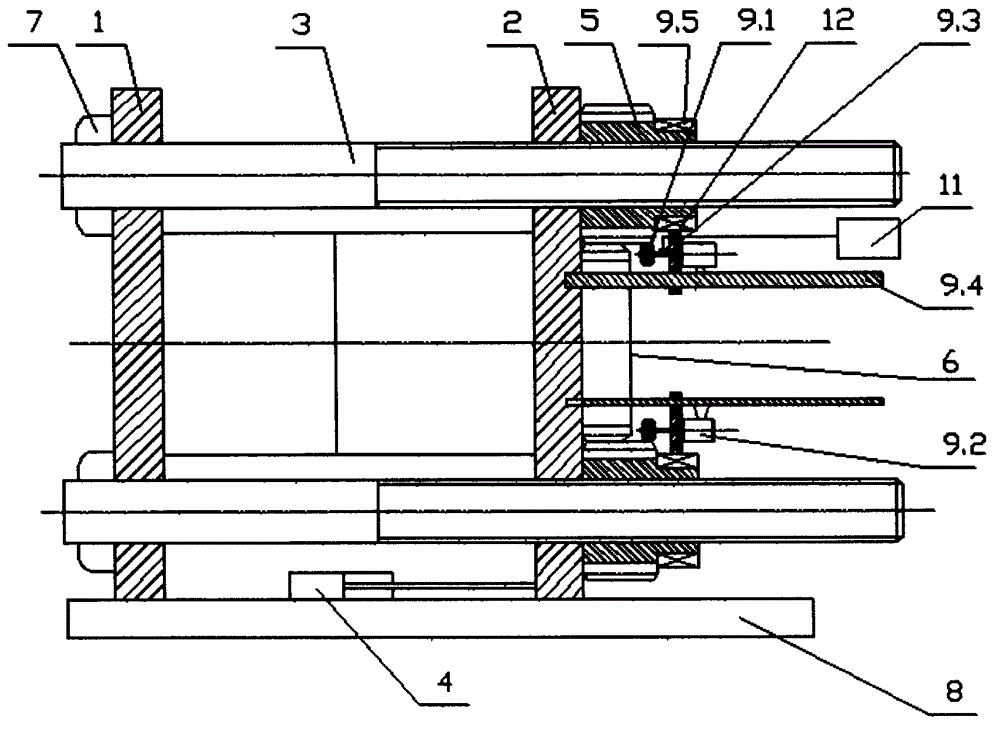

Self-locking type mold closing mechanism based on two-plate machine

The invention discloses a self-locking type mold closing mechanism based on a two-plate machine. The mold closing mechanism comprises a fixed mold plate (1), a movable mold plate (2), pull rods (3) and a mold moving oil cylinder (4), wherein the fixed mold plate (1) is fixed at one ends of the pull rods (3), the other ends of the pull rods (3) are sleeved by the movable mold plate (2), and a piston end of the mold moving oil cylinder (4) is connected with the movable mold plate (2) to drive the movable mold plate (2) to move; and the mold closing mechanism further comprises a mold locking structure, the mold locking structure comprises rear screw nuts (5) which are in one-to-one correspondence with the pull rods (3), a large gear ring (6) and a power mechanism for driving the large gear ring (6) to rotate, the rear screw nuts (5) are screwed on the pull rods (3), the outer edges of the rear screw nuts (5) are set to be like gears, and the large gear ring is meshed with the rear screw nuts (5) under the drive of the power mechanism and drives the rear screw nuts to rotate on the corresponding pull rods. According to the mold closing mechanism disclosed by the invention, a mold locking oil cylinder is not required, and energy consumption in mold locking is reduced by self-locking of the mechanism.

Owner:CHINA JILIANG UNIV

Mold closing mechanism of self-locking type two-plate machine

InactiveCN104527001AStrong self-locking effectReduce energy consumptionSelf lockingEnergy consumption

The invention discloses a mold closing mechanism of a self-locking type two-plate machine. The mold closing mechanism comprises a fixed mold plate (1), a movable mold plate (2), pull rods (3) and a mold moving oil cylinder (4), wherein the fixed mold plate (1) is fixed at one ends of the pull rods (3), the other ends of the pull rods (3) are sleeved by the movable mold plate (2), and a piston end of the mold moving oil cylinder (4) is connected with the movable mold plate (2) to drive the movable mold plate (2) to move; and the mold closing mechanism further comprises a mold locking structure, the mold locking structure comprises rear screw nuts (5) which are in one-to-one correspondence with the pull rods (3), a large gear ring (6) and a power mechanism for driving the large gear ring (6) to rotate, the rear screw nuts (5) are screwed on the pull rods (3), the outer edges of the rear screw nuts (5) are set to be like gears, and the large gear ring is meshed with the rear screw nuts (5) under the drive of the power mechanism and drives the rear screw nuts to rotate on the corresponding pull rods. According to the mechanism disclosed by the invention, a mold locking oil cylinder is not required, and energy consumption in mold locking is reduced by self-locking of the mechanism.

Owner:CHINA JILIANG UNIV

Self-locking mold clamping mechanism based on two-platen machine

The invention discloses a self-locking type mold closing mechanism based on a two-plate machine. The mold closing mechanism comprises a fixed mold plate (1), a movable mold plate (2), pull rods (3) and a mold moving oil cylinder (4), wherein the fixed mold plate (1) is fixed at one ends of the pull rods (3), the other ends of the pull rods (3) are sleeved by the movable mold plate (2), and a piston end of the mold moving oil cylinder (4) is connected with the movable mold plate (2) to drive the movable mold plate (2) to move; and the mold closing mechanism further comprises a mold locking structure, the mold locking structure comprises rear screw nuts (5) which are in one-to-one correspondence with the pull rods (3), a large gear ring (6) and a power mechanism for driving the large gear ring (6) to rotate, the rear screw nuts (5) are screwed on the pull rods (3), the outer edges of the rear screw nuts (5) are set to be like gears, and the large gear ring is meshed with the rear screw nuts (5) under the drive of the power mechanism and drives the rear screw nuts to rotate on the corresponding pull rods. According to the mold closing mechanism disclosed by the invention, a mold locking oil cylinder is not required, and energy consumption in mold locking is reduced by self-locking of the mechanism.

Owner:CHINA JILIANG UNIV

Self-locking mold clamping mechanism of injection molding machine

InactiveCN104476742BStrong self-locking effectReduce energy consumptionSelf lockingInjection molding machine

The inventiondiscloses a self-locking clamping mechanism of an injection molding machine. The self-locking clamping mechanism comprises a fixed mold plate (1), a movable mold plate (2), pull rods (3) and a mold moving oil cylinder (4), wherein the fixed mold plate (1) is fixed to one end of the pull rods (3), the movable mold plate (2) is arranged at the other end of the pull rods (3) in a sleeving manner, and a piston end of the mold moving oil cylinder (4) is connected with the movable mold plate (2) to drive the movable mold plate (2) to move. The clamping mechanism further comprises a mold locking structure, wherein the mold locking structure comprises rear nuts (5) corresponding to the pull rods (3) in a one-to-one mode, a large gear ring (6) and a power mechanism for driving the large gear ring (6) to rotate, the rear nuts (5) are screwed onto the pull rods (3), the outer edge of each rear nut (5) is in a gear shape, and the large gear ring is meshed with the rear nuts (5) respectively under the drive of the power mechanism and drives the rear nuts to rotate on the corresponding pull rods. The self-locking clamping mechanism does not need a mold locking oil cylinder and reduces the energy consumption of mold locking through self-locking between mechanisms.

Owner:CHINA JILIANG UNIV

Middle seat of sewing machine

InactiveCN106149228AHigh transmission precisionImprove sewing precisionSewing-machine control devicesDesign technologyEngineering

The invention discloses a middle seat of a sewing machine, and belongs to the technical field of design of sewing machine parts. The middle seat comprises a mounting plate, a shell and a clamping seat, wherein the whole middle seat of the sewing machine is obtained by casting; the clamping seat is located on the left side of the mounting plate, and a gap is reserved between the clamping seat and the mounting plate; the shell is located on the right side of the mounting plate; the clamping seat, the mounting plate and the shell form a whole; the upper surface of the shell is a casting surface and does not need to be machined; both the bottom surface and the side surface of the shell are combination surfaces, so that the precision requirement is high, and the bottom surface and the side surface need to be milled and formed on a milling machine. According to the middle seat of the sewing machine, the transmission precision of the sewing machine can be improved favorably, and the phenomenon that the sewing machine is blocked by impurities, such as thread ends and shreds, entering the sewing machine in a sewing process is effectively prevented; an enough space for accommodating transmission parts is reserved in the shell, and no interference with other components of the sewing machine is avoided; all the parts in the shell have enough high shape and position precision.

Owner:CHIZHOU TAISHENG SEWING MACHINERY TECH CO LTD

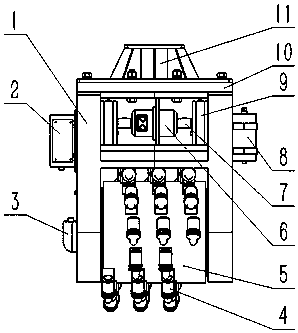

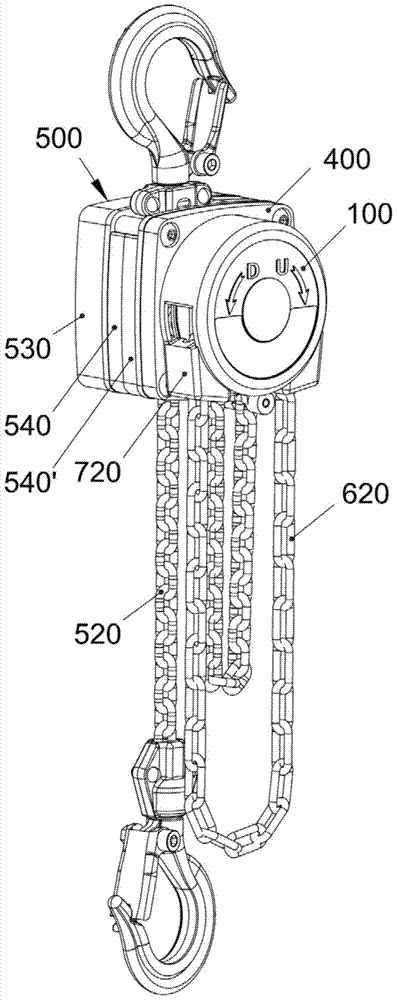

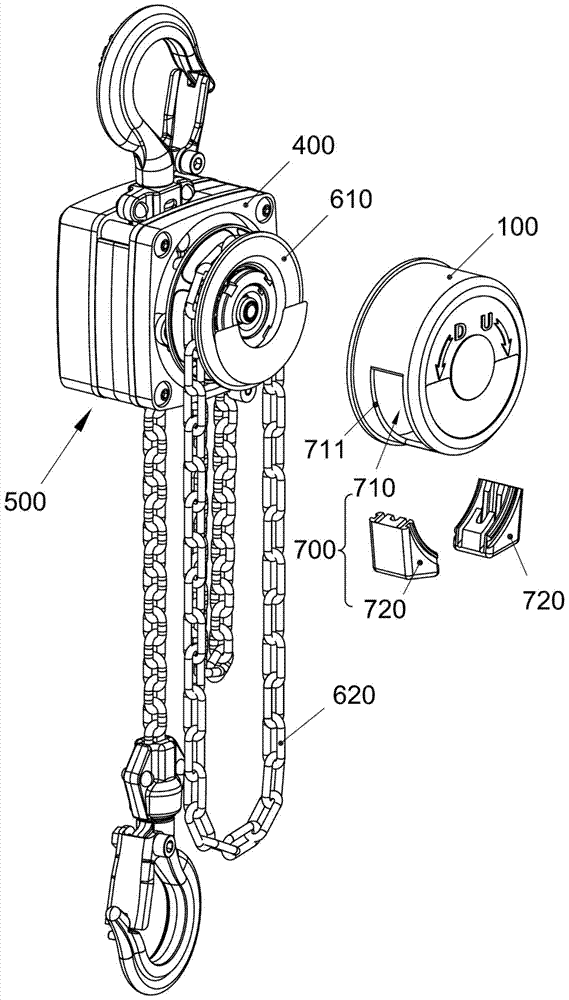

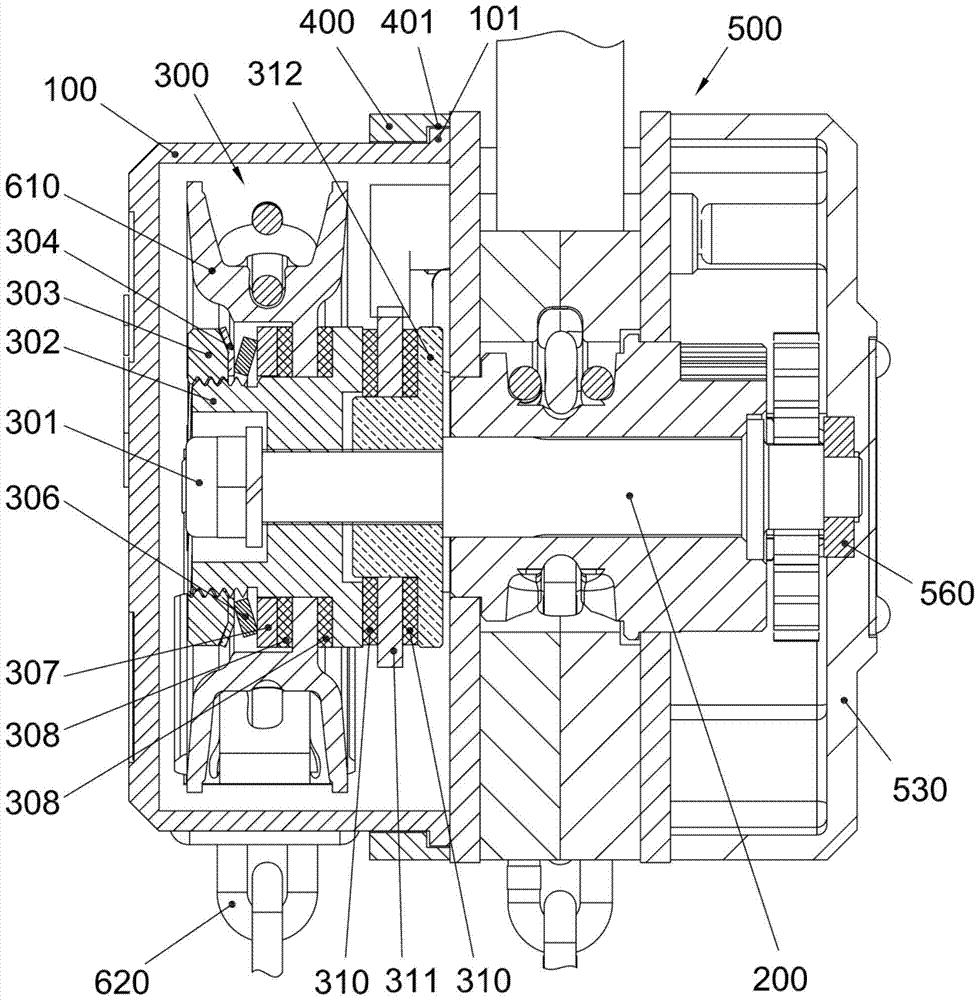

a chain hoist

ActiveCN104760898BCan be used in a wide rangeExtended service lifePortable liftingLong axisEngineering

Owner:CHONGQING VITAL ELEVATORING EQUIP

A kind of manufacturing method of automobile plastic spare parts

ActiveCN112123093BPrevent disengagementPrevent stuck and other phenomenaEdge grinding machinesGrinding drivesSpare partAutomotive engineering

The invention relates to a manufacturing method of plastic parts for automobiles, which uses a finishing machine, which includes a workbench, a clamping mechanism and a grinding mechanism. The right side of the tightening mechanism is provided with a grinding mechanism, and the clamping mechanism adopted in the present invention clamps the inside of the automobile plastic parts, and the clamping mechanism snaps into the internal thread groove of the automobile plastic parts, and the screw thread inside it The grooves are correspondingly snapped in to prevent the automotive plastic parts from leaving the workbench when they are being rotated and polished, and the surface of the automotive plastic parts is polished by a grinding mechanism. The grinding rod stretches according to the surface shape of the automotive plastic parts, so that It fits perfectly with the outer surface of the automotive plastic parts, and the left end surface of the fixing rod and the clamping rod is equipped with a rubber layer to prevent the fixing rod and the clamping rod from causing jamming when the automotive plastic parts are clamped. injuries etc.

Owner:柳州精特汽配制造有限公司

A floor paint scraping device and floor paint coating robot

ActiveCN113374232BEnsure consistencyGuaranteed uniformityBuilding constructionsStructural engineeringMechanical engineering

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

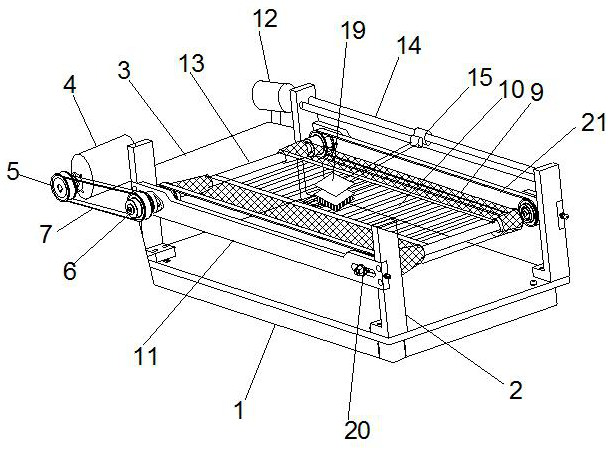

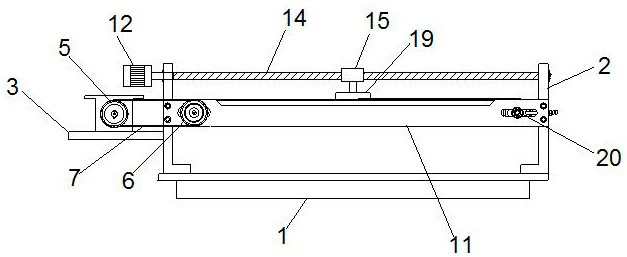

A water tank filter conveyor belt for a double-sided grinder

ActiveCN112428137BSmooth runningFlexible operationLapping machinesMoving filtering element filtersElectric machineryEngineering

The invention discloses a water tank filter conveyor belt used for a double-sided grinder; it includes a base, a support rod and a connecting arm; support rods are provided at the upper four corners of the base, and connecting arms are arranged in parallel between the support rods; One end of the base is provided with a supporting plate, and the supporting plate is provided with a reduction motor, and the reduction motor is driven and connected with the first sprocket; the position close to both ends of the connecting arm is provided with a rotating rod, and the rotating rod is close to the deceleration One end of the motor is provided with a second sprocket; the rotating rod is connected to the connecting arm in rotation, and the inner side of the rotating rod close to the connecting arm is provided with a roller, and a silk screen is arranged on the roller, and the wire mesh is formed on the rotating rod through the roller. Circular rotation; there are multiple connecting rods between the screens; the chain is driven by a small gear motor to make the screen run, and the support transition of the nylon roller solves the problem of the wire mesh conveyor belt being entangled and broken during operation. The conveyor belt runs more smoothly and flexibly, which improves the filtration efficiency.

Owner:新乡市万华数控设备有限公司

Mold opening and closing method of self-locking mold clamping mechanism based on two-platen machine

InactiveCN104527004BStrong self-locking effectReduce energy consumptionSelf lockingEnergy consumption

The invention discloses a mold opening and closing method for a self-locking type mold closing mechanism based on a two-plate machine. The mold opening and closing method is based on the self-locking type mold closing mechanism, and the self-locking type mold closing mechanism comprises a fixed mold plate, a movable mold plate, pull rods and a mold moving oil cylinder, wherein the fixed mold plate is fixed at one ends of the pull rods, the other ends of the pull rods are sleeved by the movable mold plate, and a piston end of the mold moving oil cylinder is connected with the movable mold plate to drive the movable mold plate to move; and the mold closing mechanism further comprises a mold locking structure, the mold locking structure comprises rear screw nuts which are in one-to-one correspondence with the pull rods, a large gear ring and a power mechanism for driving the large gear ring to rotate, the rear screw nuts are screwed on the pull rods, the outer edges of the rear screw nuts are set to be like gears, and the large gear ring is meshed with the rear screw nuts under the drive of the power mechanism and drives the rear screw nuts to rotate on the corresponding pull rods. According to the mold opening and closing method disclosed by the invention, a mold locking oil cylinder is not required, and energy consumption in mold locking is reduced by self-locking of the mechanism.

Owner:CHINA JILIANG UNIV

Live switching method, device, computer equipment and storage medium

ActiveCN110213596BPrevent stuck and other phenomenaTransmissionSelective content distributionStreaming dataLive video

The present application relates to a live switching method, device, computer-readable storage medium, and computer equipment. The method includes: acquiring the live stream data corresponding to each access server in multiple historical time periods, and acquiring the live stream data of each access server according to the live stream data. The live video frame state data and / or live audio frame state data corresponding to each historical time period; according to the live video frame state data and / or live audio frame state data corresponding to each access server in each historical time period, each The live stream quality corresponding to the access server; select the target access server according to the live stream quality corresponding to the current playback access server and the live stream quality corresponding to the candidate access server; use the target access server as the current playback access server to Make the playback terminal pull the live streaming data from the target access server. The solution provided by this application can improve the accuracy of live switching.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Self-locking two-platen machine mold clamping mechanism

The invention discloses a mold closing mechanism of a self-locking type two-plate machine. The mold closing mechanism comprises a fixed mold plate (1), a movable mold plate (2), pull rods (3) and a mold moving oil cylinder (4), wherein the fixed mold plate (1) is fixed at one ends of the pull rods (3), the other ends of the pull rods (3) are sleeved by the movable mold plate (2), and a piston end of the mold moving oil cylinder (4) is connected with the movable mold plate (2) to drive the movable mold plate (2) to move; and the mold closing mechanism further comprises a mold locking structure, the mold locking structure comprises rear screw nuts (5) which are in one-to-one correspondence with the pull rods (3), a large gear ring (6) and a power mechanism for driving the large gear ring (6) to rotate, the rear screw nuts (5) are screwed on the pull rods (3), the outer edges of the rear screw nuts (5) are set to be like gears, and the large gear ring is meshed with the rear screw nuts (5) under the drive of the power mechanism and drives the rear screw nuts to rotate on the corresponding pull rods. According to the mechanism disclosed by the invention, a mold locking oil cylinder is not required, and energy consumption in mold locking is reduced by self-locking of the mechanism.

Owner:CHINA JILIANG UNIV

A network security operation and maintenance management system based on bastion machine

ActiveCN113364758BAvoid inconvenienceEnsure safetyTransmissionData acquisitionMaintenance management

The invention discloses a network security operation and maintenance management system based on a bastion host, belonging to the technical field of operation and maintenance management. The system includes an operation and maintenance personnel security authentication layer, an operation and maintenance data collection layer, an operation and maintenance data storage analysis processing layer, and an operation and maintenance process security management layer; the operation and maintenance personnel security authentication layer is used for the security authentication and login of the operation and maintenance personnel; The operation and maintenance data acquisition layer is used to collect data in the operation and maintenance process; the operation and maintenance data storage analysis processing layer is used to store, analyze and process the data generated in the operation and maintenance process, and optimize the operation and maintenance scene; The operation and maintenance process safety management layer is used to monitor and warn abnormal behaviors in the operation and maintenance process; the present invention can realize the optimization of the operation and maintenance scene, and is more suitable for the operation and maintenance operation of each operation and maintenance personnel, and can be based on Changes in time intervals during operation and maintenance operations are used for security operation and maintenance management.

Owner:珠海市鸿瑞信息技术股份有限公司

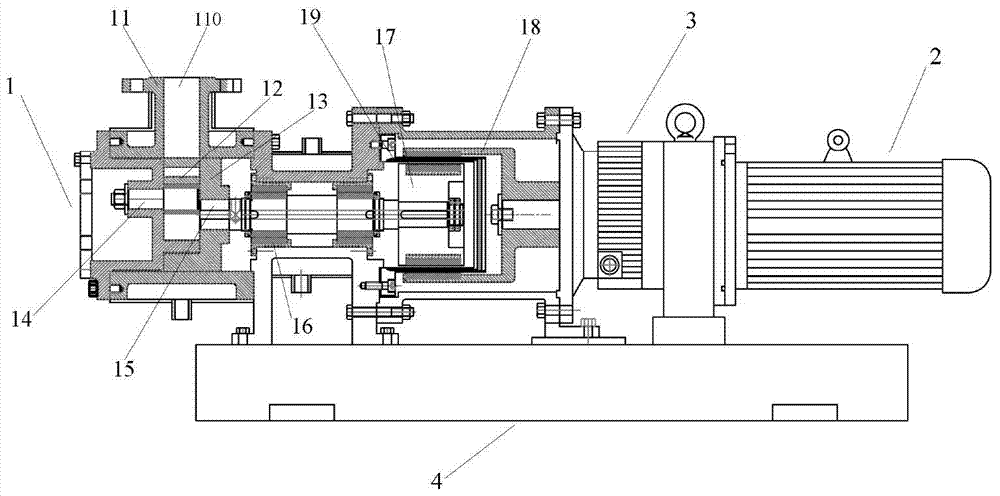

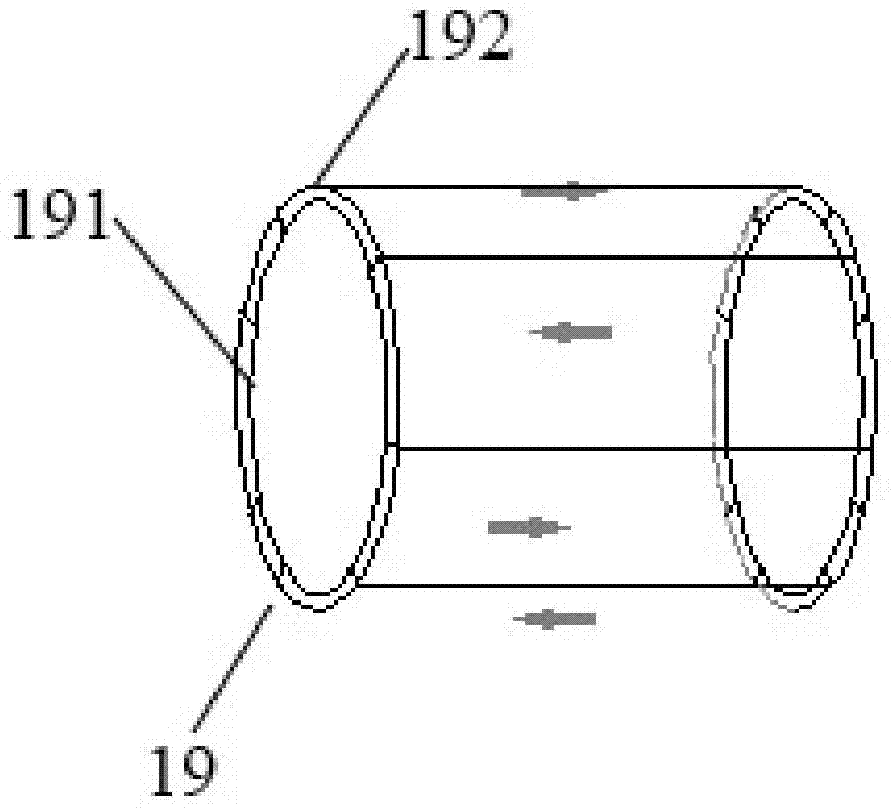

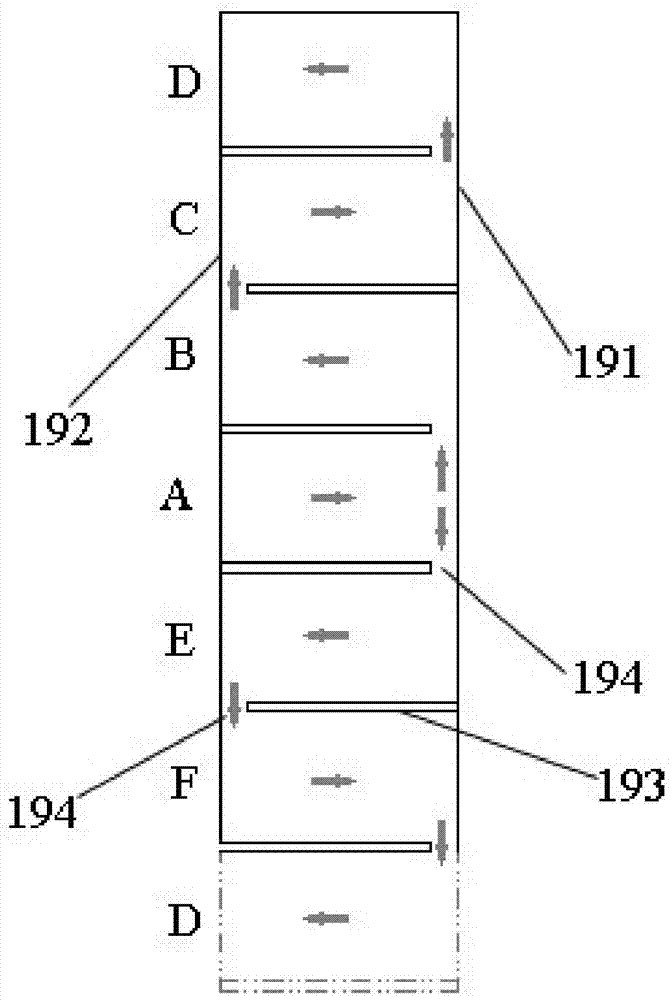

A transfer pump for conveying solid-liquid mixture materials

ActiveCN105464964BPlay the role of heat dissipationReduce maintenance frequencyRotary piston pumpsRotary piston liquid enginesDrive shaftThermal insulation

Provided is a transfer pump (1) for conveying a solid-liquid mixture. The transfer pump comprises a pump body (11), an inner rotor (12), an outer rotor (13), a hinge pin (14), a transmission shaft (15), a bearing assembly (10), an inner magnetic coupling (17), an external magnetic coupling (18) and a thermal insulation and isolation jacket (19), wherein a cavity defined by the outer rotor, the transmission shaft and the bearing assembly is a high pressure cavity (111); a transmission shaft opening (112) is provided on the transmission shaft of the high pressure cavity near a material inlet (110), and the transmission shaft opening is used for allowing the solid-liquid mixture to enter the transmission shaft; and an internal hollow channel (113) is provided between one end of the transmission shaft near the thermal insulation and isolation jacket and the transmission shaft opening, and the internal hollow channel is used for conveying the solid-liquid mixture. The transfer pump enables the solid-liquid mixture pumped into the pump body gap and cavity to flow out of the pump body through internal channel circulation, with no blockage occurring to the the pump body; and a thermal insulation device is provided both inside and outside the pump body, and no phenomenon of pump body blockage due to material crystallization resulting from a decrease in material temperature occurs.

Owner:TAICANG SHUNDA MAGNETIC PUMP TECH

Mold Opening and Closing Method of Clamping Mechanism of Self-locking Two-platen Machine

Owner:CHINA JILIANG UNIV

Hydraulic rotary mechanism of new segment assembly machine

ActiveCN106678090BGuaranteed stabilityGuaranteed accuracyUnderground chambersServomotorsHydraulic motorEquilibrium control

The invention relates to a novel hydraulic rotation mechanism of a segment erector. The novel hydraulic rotation mechanism comprises a filter, a plunger pump, a check valve, an electric-hydraulic proportional direction valve, an overflow valve, a first pressure reduction valve, a second pressure reduction valve, a pressure gauge, a pressure sensor, a shuttle valve, a balance valve, a three-position ball valve, a two-way overflow valve, an energy accumulator, two hydraulic motors, a brake and a rotary encoder. A balance control module of the hydraulic motors is composed of the balance valve and the two-way overflow valve, and two-way safety protection can be provided; the pressure compensation type electric-hydraulic proportional direction valve with loads is selected for use, and precision and stability of the splicing position are ensured; the hydraulic motors with mechanical braking are adopted, and reliability of rotation movement is ensured; and the hydraulic impact generated in the start, stop and reversing processes of the segment erector is eliminated, the device damage situation such as the situation that the novel hydraulic rotation mechanism gets stuck is effectively prevented in the movement process, and the operation efficiency is improved.

Owner:辽宁三三工业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com