A water tank filter conveyor belt for a double-sided grinder

A technology of double-sided grinding and conveyor belt, applied in the field of grinding machines, to achieve the effect of improving filtration efficiency, speeding up removal rate and preventing sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

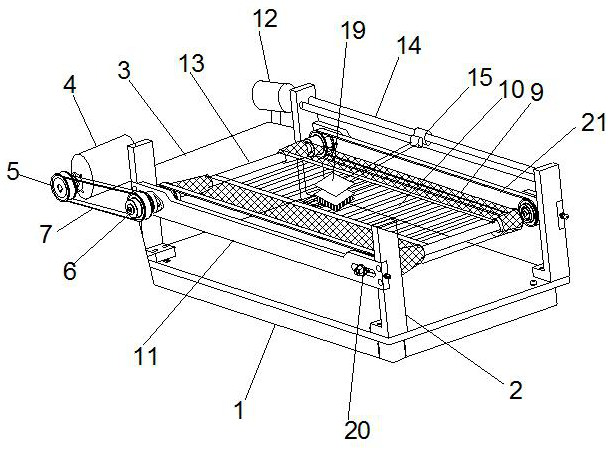

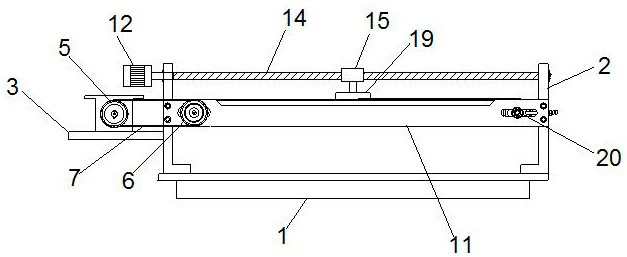

[0039] Such as Figure 1-4As shown, a water tank filter conveyor belt for a double-sided grinder; it includes a base 1, a support rod 2, and a connecting arm 11; A connecting arm 11 is provided; one end of the base 1 is provided with a supporting plate 3, and the supporting plate 3 is provided with a geared motor 4, and the geared motor 4 is driven and connected with a first sprocket 5; the connecting arm 11 is close to two ends The position runs through a rotating rod 13, and the end of the rotating rod 13 near the reduction motor 4 is provided with a second sprocket 6, and a chain 7 is connected between the first sprocket 5 and the second sprocket 6; the rotating rod 13 Rotatingly connected with the connecting arm 11, the rotating rod 13 is provided with a roller 8 near the inner side of the connecting arm 11, and the roller 8 is provided with a screen 9, and the screen 9 forms a circular rotation on the rotating rod 13 through the roller 8; A plurality of connecting rods 1...

Embodiment 2

[0042] Such as Figure 5 , 7 As shown, a first threaded rod 14 is provided between the connecting arms 11 on the side away from the geared motor 4, and one end of the first threaded rod 14 is connected with a servo motor 12, and the servo motor 12 is fixed on the bracket. On the plate 3; the first threaded rod 14 is rotatably connected to the connecting arm 11 through the provided bearing; one side of the first threaded rod 14 is provided with a slide bar 16, and the two ends of the slide bar 16 are connected to the connecting arm 11 connected, the slide rod 16 is provided with a slider 17; the first threaded rod 14 is provided with a moving block 15, and the moving block 15 is provided with an inner screw hole, and the moving block 15 connects with the first thread through the inner screw hole The rod 14 is mated with a swivel connection.

[0043] The outer wall of the moving block 15 is connected with a connector, and is connected with the outer wall of the slider 17 throu...

Embodiment 3

[0045] Such as Image 6 As shown, on the basis of Embodiment 1, the opposite side of the screen 9 is connected with a fixed bar 22, and the fixed bar 22 rotates circularly on the rotating rod 13 through the roller 8; There are a plurality of connecting rods 10, and the screen 9 is connected through the connecting rods 10; the roller 8 is made of nylon.

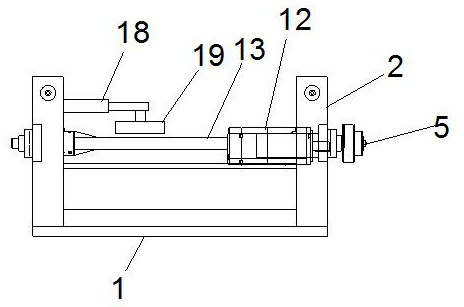

[0046] The rotating rod 13 at one end of the reduction motor 4 is provided with an adjusting mechanism 20, and the adjusting mechanism 20 includes a rotating rod 13, and one end of the rotating rod 13 runs through the connecting arm 11, and forms a sliding connection with the through groove provided with the connecting arm 11; The rotating rod 13 is connected with a second threaded rod 23, the second threaded rod 23 runs through the support rod 2, and forms a matching rotation connection with the support rod 2 through a threaded hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com