Liquid pump

A liquid pump and rotor technology, applied in the field of pumping equipment, can solve the problems of the rotor not being able to rotate and the rotor being easily stuck, and achieve the effects of noise elimination, long service life and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

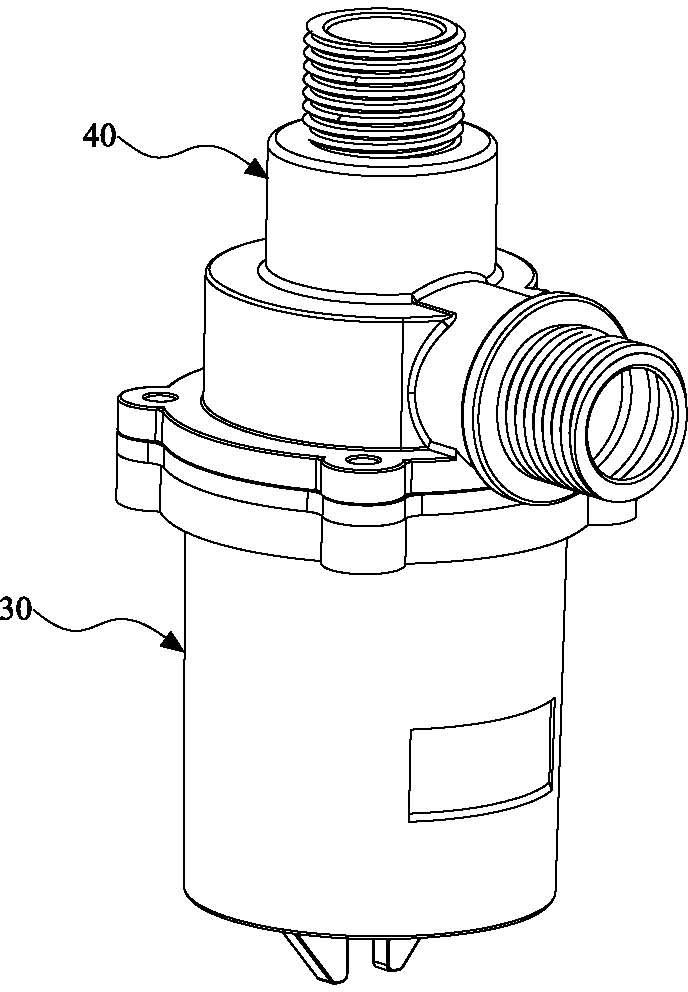

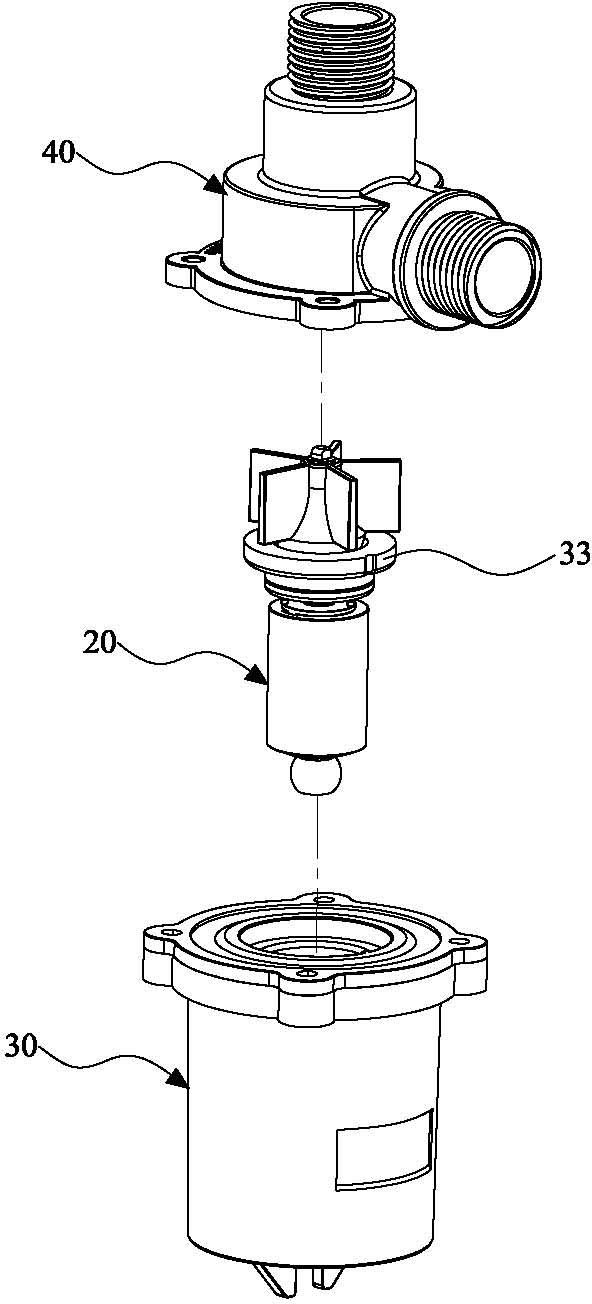

[0050] Please refer to figure 1 and figure 2 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a stator assembly 10, a rotor assembly 20, a casing 30 and a pump cover 40, and the stator assembly 10 and the rotor assembly 20 are installed in the casing 30 , the pump cover 40 is fixed on the end of the housing 30 .

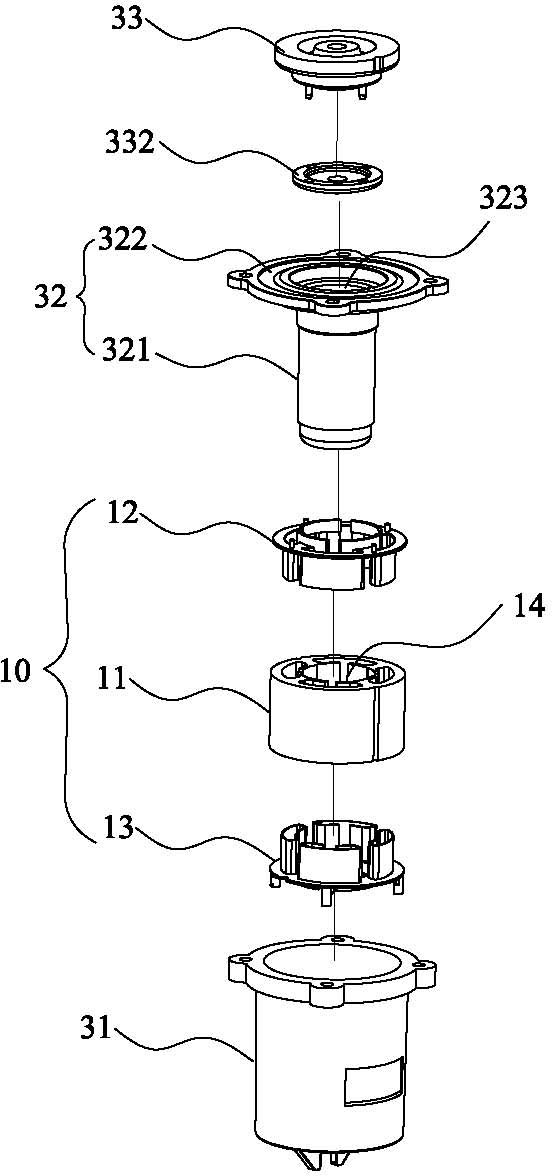

[0051] Among them, such as image 3 As shown, the housing 30 includes a motor casing 31 , a sealing spacer 32 and a sealing cover 33 . The stator assembly 10 includes a stator coil 11 , an upper jacket 12 and a lower jacket 13 .

[0052] The motor casing 31 is a hollow structure with an open upper end, and the sealing spacer 32 is installed in the hollow structure to form a second accommodating chamber 311 for installing the stator coil 11 (see Figure 5 ). The stator coil 11 is clamped by the upper jacket 12 and the lower jacket 13 and then installed in the second accommodating chamber 311 , and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com