Method for rapidly monitoring deformation by aid of ground-based three-dimensional laser scanner

A three-dimensional laser and scanner technology, applied in the direction of optical devices, instruments, measuring devices, etc., can solve problems such as the inability to achieve rapid feedback of monitoring results, and achieve the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

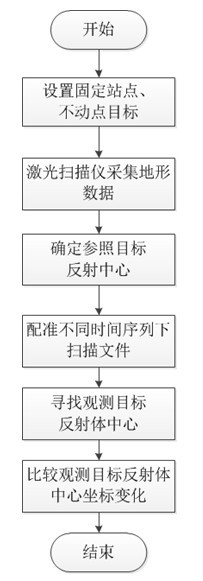

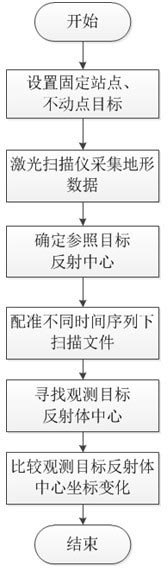

[0019] The method includes a method for rapidly monitoring deformation of an area-type three-dimensional laser scanner.

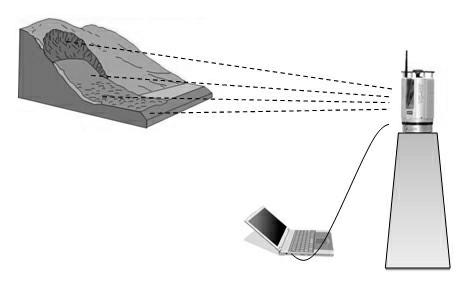

[0020] (1) First set up a suitable fixed site and fixed point target, and fix the ground-based 3D laser scanning on the pile dial. Use a threaded screw to fix the instrument, scale marks, and place the scanner to align with the scale. When the scanner is fixed on the pile, use a threaded bolt. The unthreaded end is buckled into the dial, and the threaded end is buckled under the instrument. The instrument chassis and Pile Dial Engagement. After determining the fixed site, paste 3-5 circular reflectors with a diameter of 5cm within 30m around the fixed site where the instrument is placed for calibration, and ensure that these reflectors are fixed throughout the monitoring process.

[0021] (2) The laser scanner collects topographic data: the purpose of rough scanning is to find the tracking target position and correct the reflector more easily and quickly; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com