Testing method for simulating soil cutting effect indoors by using high pressure jet grouting technology

A technology of high-pressure rotary spray and test method, applied in the field of construction engineering, can solve the problems of waste of construction resources, high uncertainty, poor foundation treatment effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

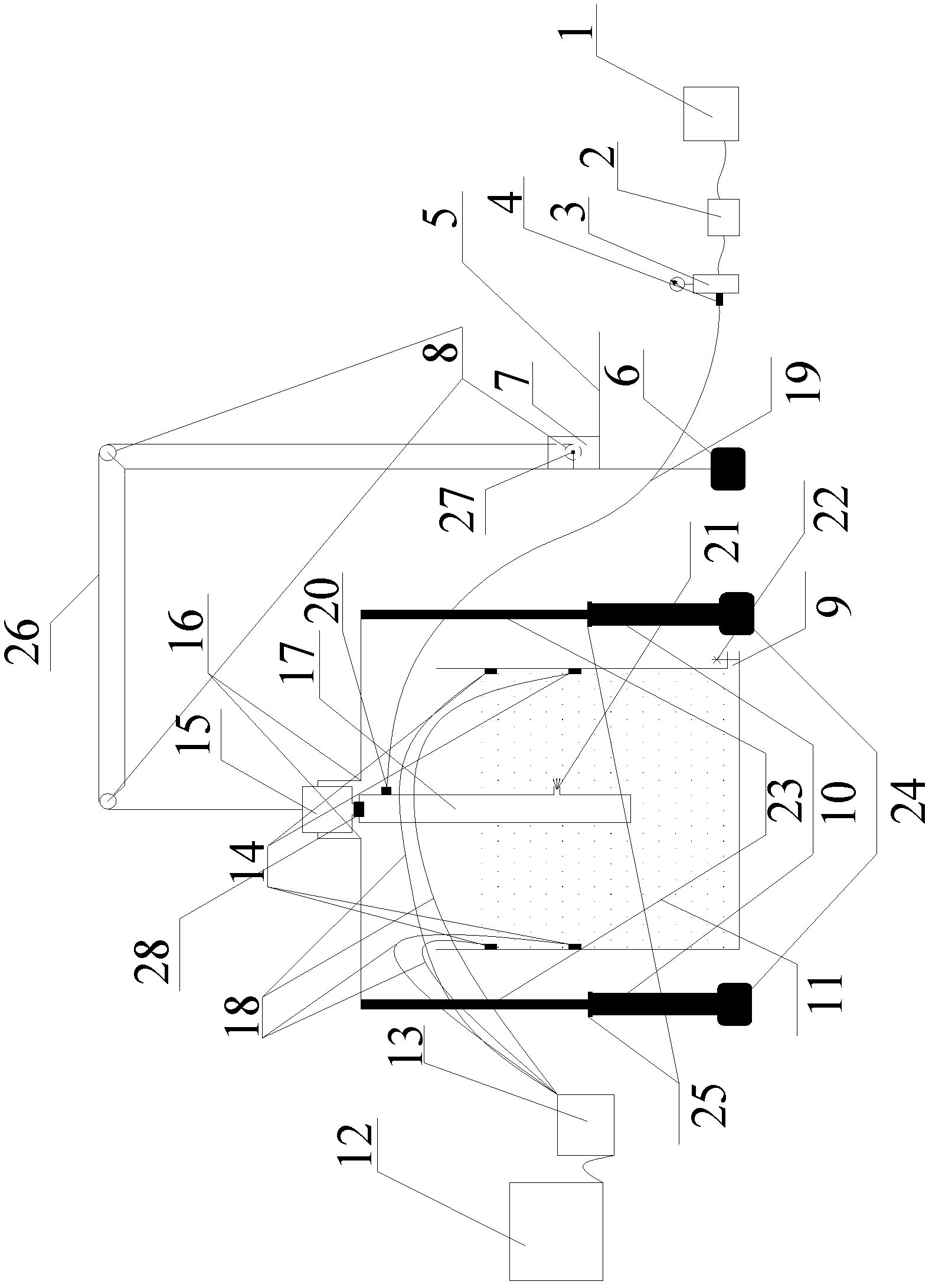

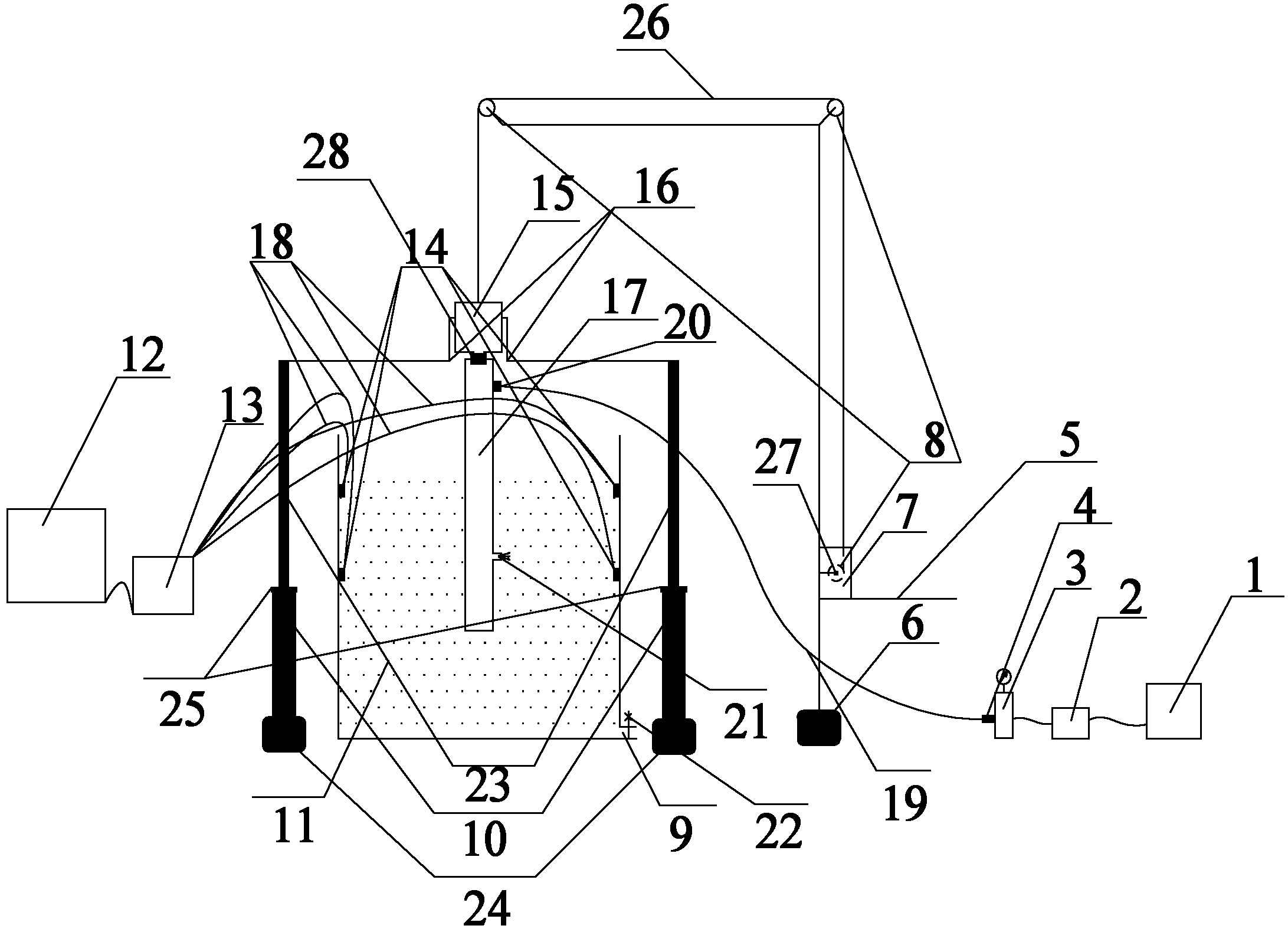

Method used

Image

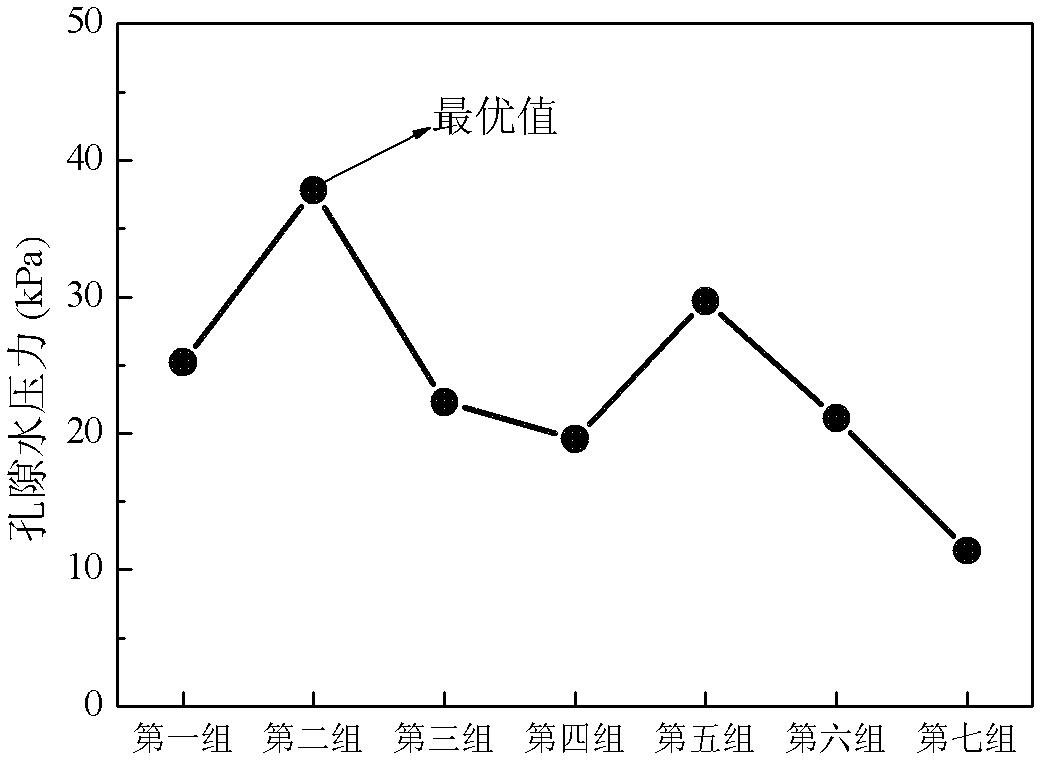

Examples

Embodiment Construction

[0032] Embodiments of the present invention are described in detail below, and the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are provided, but the protection scope of the present invention is not limited to the following embodiments.

[0033] The following steps are carried out in this embodiment:

[0034] The first step is to clarify the geological conditions of the site by consulting the engineering geological survey report of the construction site: the top layer (0.0-1.6m) is the backfill soil layer; the lower layer (1.6-15.5m) is the clayey silt layer; the lower layer ( 15.5-25.2m) is a soft clay layer, and the next layer (25.2-35.2m) is a harder silty clay layer. The water content of the soil layer in the construction area is roughly 20-40%. The construction area mainly involves clayey silt layer and soft clay layer. The unconfined compressive strength of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com