Device and method for in-plane shear test of ceramic-based fiber bundle composite material

A composite material and test method technology, applied in the field of ceramic matrix fiber bundle composite material in-plane shear test device, to achieve the effects of reducing processing cost, improving success rate, and facilitating centering and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0057] This embodiment provides an in-plane shear test device for a ceramic-based fiber bundle composite material, including: an in-plane shear sample, an in-plane shear sample centering sample preparation device, and an in-plane shear fixture.

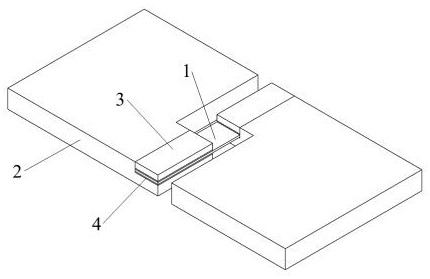

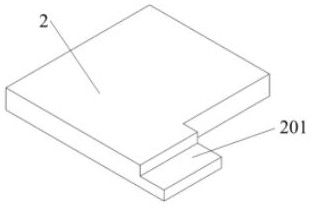

[0058] Such as figure 1 As shown, the in-plane shear specimen is composed of sheet-shaped ceramic matrix fiber bundle composites 1 (see figure 2 ), two reinforcement sheets 2 and two cover plates 3; if image 3 As shown, one end of the reinforcing sheet 2 is designed with a stepped structure 201; the reinforcing sheet 2 is made of light acrylic material; the sheet-shaped ceramic-based fiber bundle composite material 1 is pasted on the stepped structure of the reinforcing sheet by epoxy glue 4 201 ; the cover plate 3 is pasted on the upper surface of the sheet-shaped ceramic-based fiber bundle compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com