Detection method for train bearing fault

A detection method and train technology, applied in the detection field, can solve problems such as strong randomness, poor practical applicability, damage to bearing running-in conditions, etc., and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

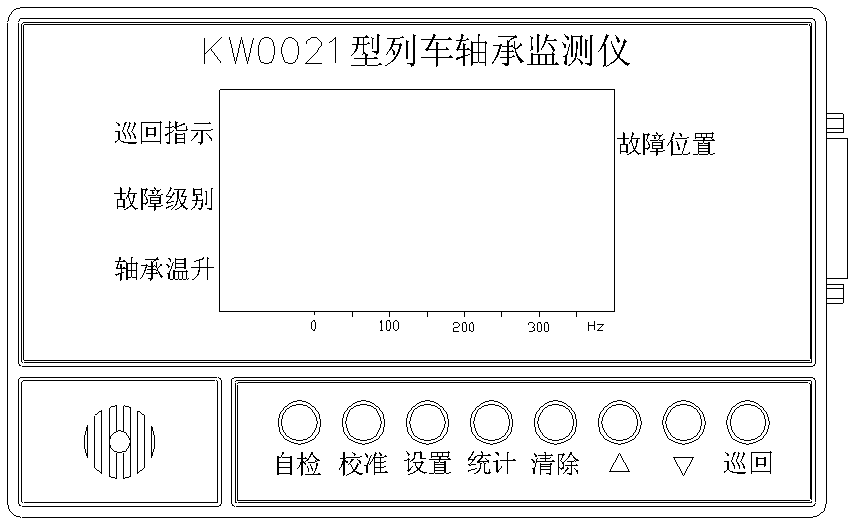

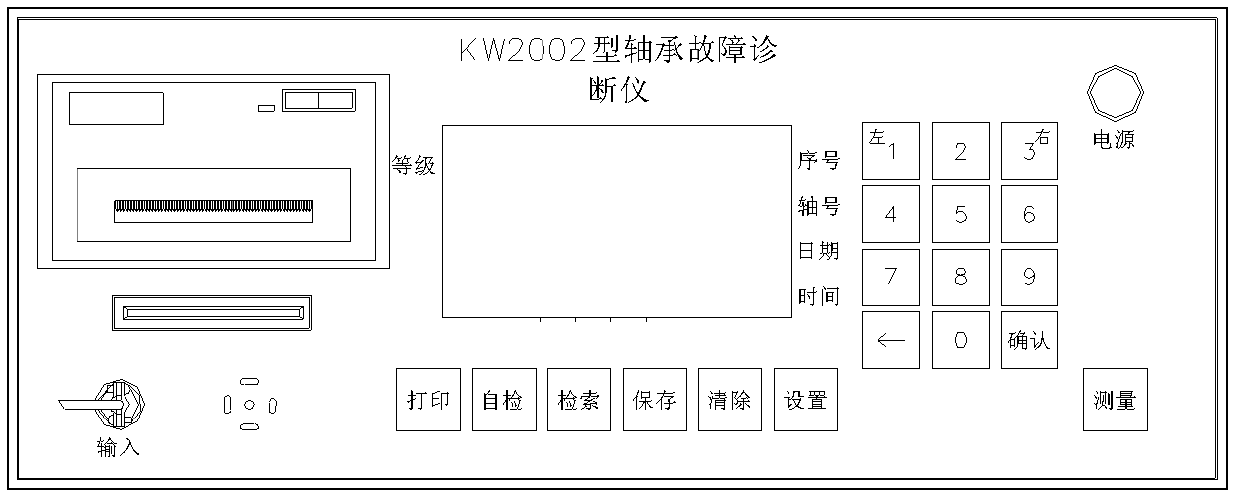

[0108] This detection method is applied to the KW2002 bearing fault diagnosis instrument produced by Tianjin Qixuan Electronics Co., Ltd. ( figure 2 ) and KW0021 Train Bearing Monitor ( figure 1 ) of two products.

[0109] The built-in analysis software of the above two products adopts 4 times of measurement and related processing procedures, and the process is as follows:

[0110] 1. Perform 512-point sampling and A / D conversion on the sensor output signal after amplification and filtering;

[0111] 2. Perform fast Fourier transform on the above transformation result to obtain the first group of 200 power spectrum components;

[0112] 3. Delay for 1 minute, repeat the above 1 and 2, and get the second group of 200 power spectrum components;

[0113] 4. Delay for 1 minute, repeat the above 1 and 2, and get the third group of 200 power spectrum components;

[0114] 5. Delay for 1 minute, repeat the above 1 and 2, and get the fourth group of 200 power spectrum components; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com