Rapid quality control board for surface-mounted diodes

A diode and patch technology, which is applied in the field of patch diode rapid quality inspection board, can solve the problems of low efficiency and high labor intensity of workers, and achieve the effect of improving weighing efficiency and facilitating appearance inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

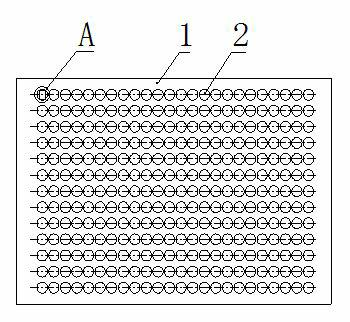

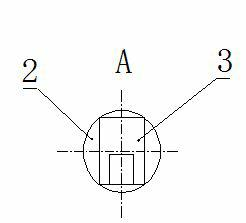

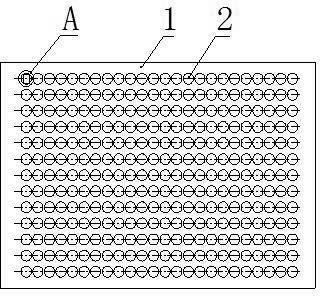

[0008] Such as figure 1 , 2 As shown, including the plate body 1, the upper end surface of the plate body 1 is evenly distributed with a number of circular holes 2 whose bottom does not penetrate the lower end surface of the plate body.

[0009] When in use, put a number of SMD diodes 3 on the plate body 1, and move the plate body 1 through the sieve, so that the SMD diodes 3 fall into the round hole 2, and the redundant SMD diodes 3 are removed, and the diameter of the round hole 2 Slightly larger than the end surface of the long axis of the SMD diode 3, so that when the SMD diode 3 falls into the round hole 2, the end surface of the long axis faces upward, and the appearance inspection of the pins on the end surface of the long axis can be carried out. At the same time, since the number of round holes 2 on the board body 1 is fixed, the number of patch diodes 3 on it can be quickly judged, which is convenient for checking the weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com