Quick quality inspection combination tooling for surface mount diodes

A diode and chip technology, which is applied in the field of fast quality inspection combined tooling for chip diodes, can solve the problems of missed inspection, inability to judge, and the round hole cannot completely correspond to the original board body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

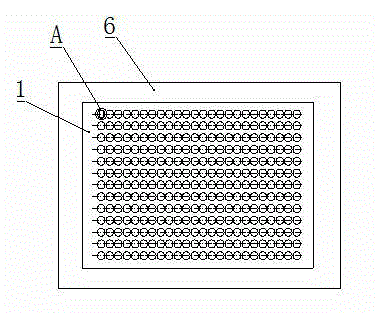

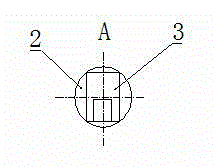

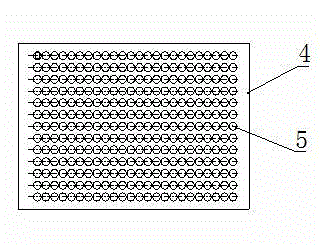

[0009] like figure 1 , 2 , 3, including a motherboard 1, a round hole 2, a limit frame 3, a male board 4, and a round hole 5.

[0010] The board body of the above-mentioned motherboard 1 is evenly distributed with a number of round holes 2 whose bottoms do not penetrate the lower end surface of the board body. Limiting frame 6 is set on the side.

[0011] The body of the male board 4 is evenly distributed with a number of round holes 5 whose bottoms do not penetrate the lower surface of the board body. The diameter of the round holes 5 is the same as that of the mother board 1, and the body of the male board 4 can just be embedded in the mother board 1. within the bounding box.

[0012] Working principle: When in use, use the motherboard 1 first, place a number of SMD diodes 3 on the body of the motherboard 1, and move the board body left and right, so that the SMD diodes 3 fall vertically into each circle of the motherboard 1 body. In the hole 2, the long axis end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com