Centrifugal deduster

A technology of dust collector and centrifugal cylinder, which is applied in the direction of separation method, dispersed particle separation, chemical instrument and method, etc. It can solve the problems of high temperature chemical corrosion resistance, many faults, low dust removal efficiency, etc., and achieve long service life and low operating cost. low dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

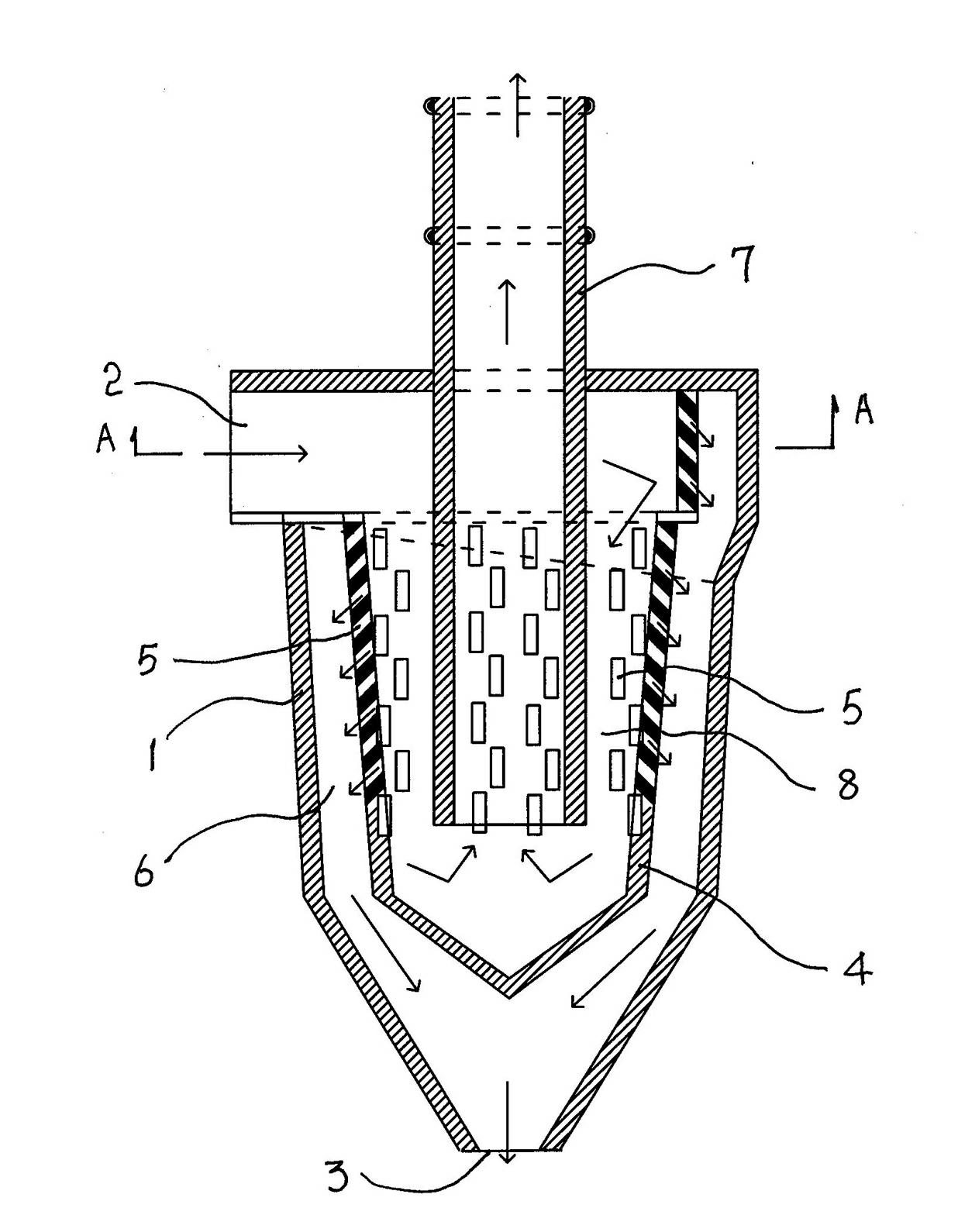

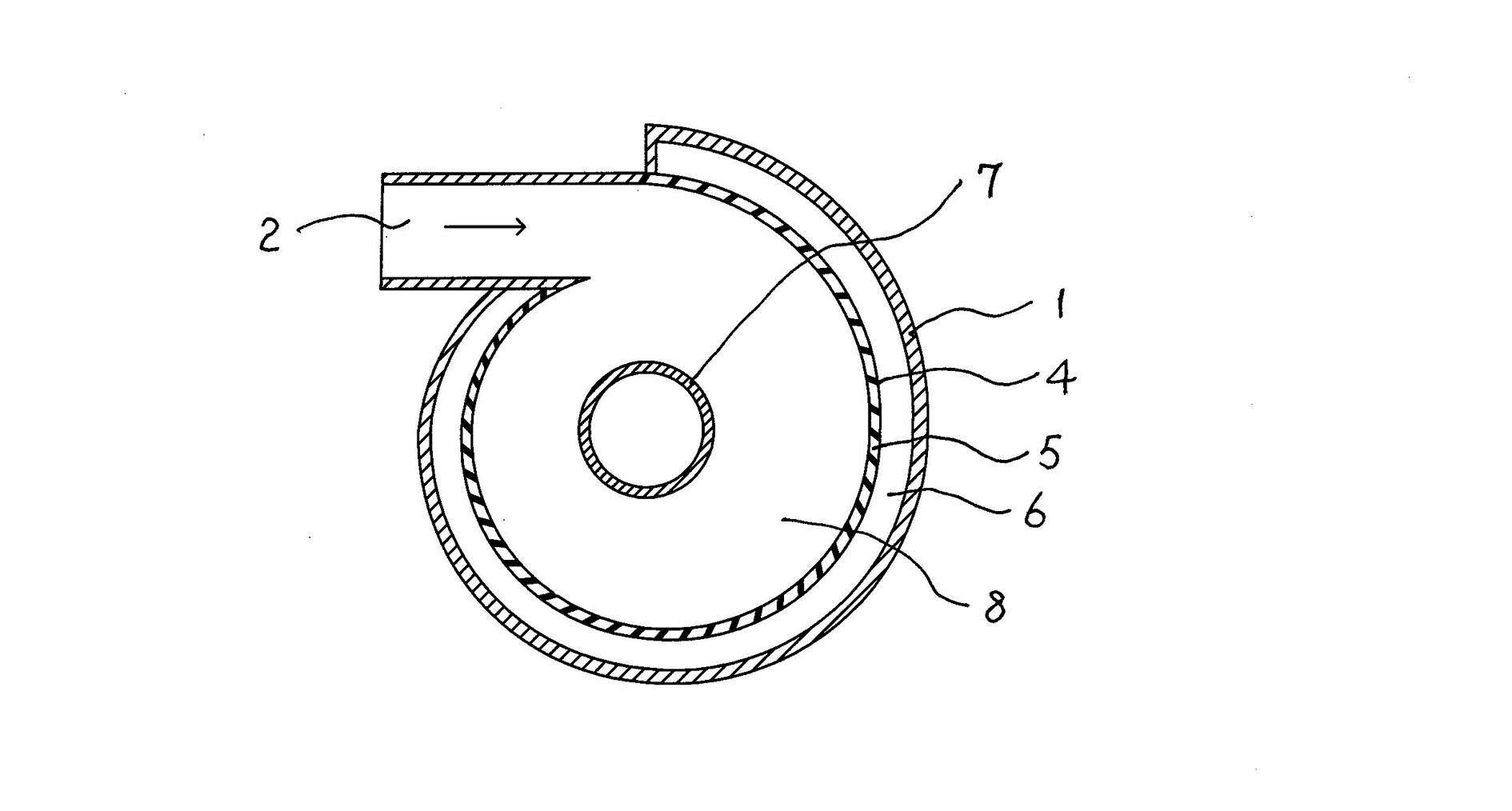

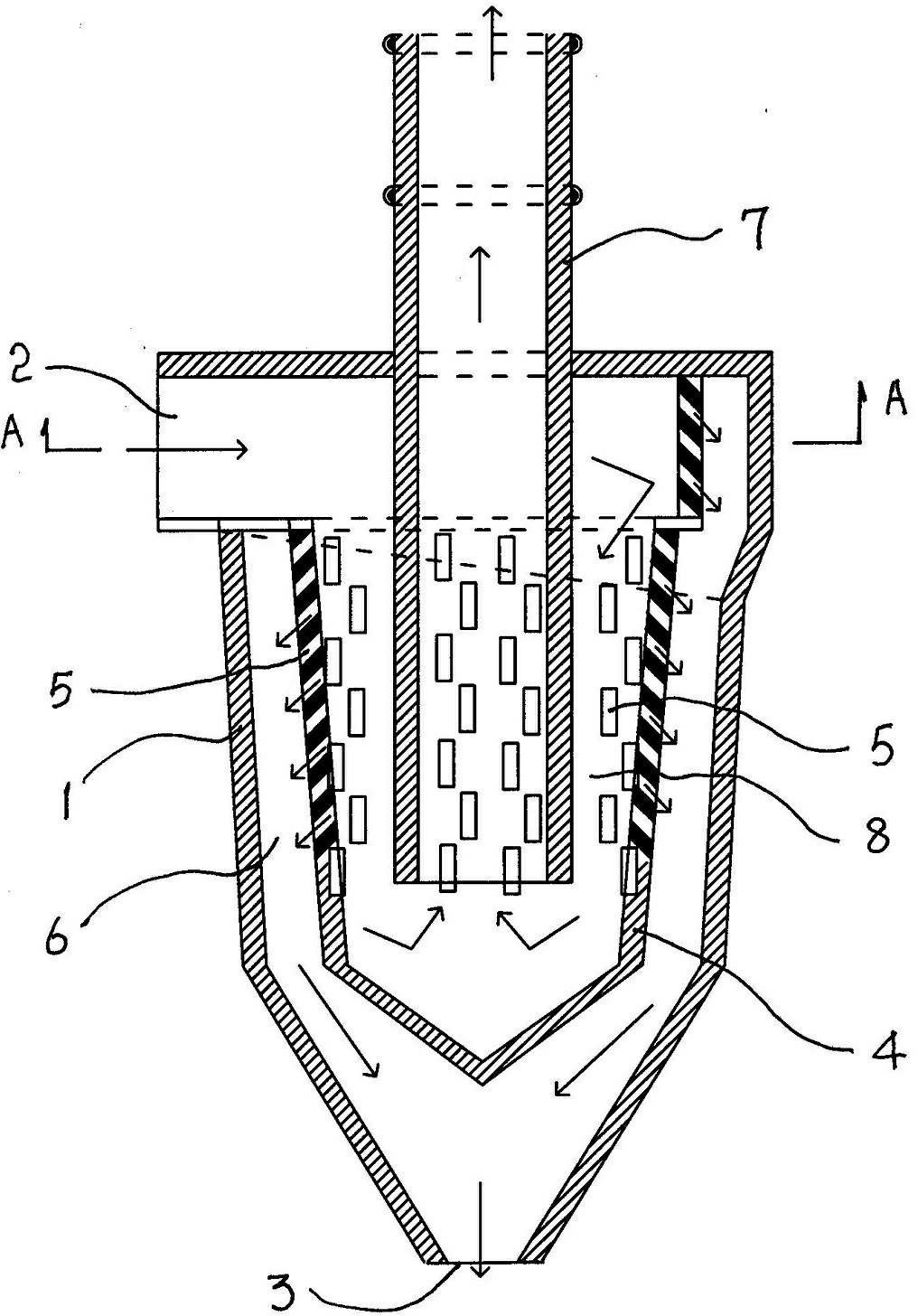

[0012] As shown in the figure, the present invention includes a body 1, which is conical, and the lower part of the body 1 shrinks radially. The upper side of the body 1 is provided with an air inlet 2, and the lower end of the body 1 is provided with a dust outlet 3, and a centrifugal cylinder 4 with a closed bottom is fixed in the body 1, and the closed bottom of the centrifugal cylinder 4 shrinks in a conical shape. The air inlet 2 is connected to the centrifugal cylinder 4 in a tangential direction, and the dust escape port 5 is evenly distributed on the side wall of the centrifugal cylinder 4, and the dust escape port 5 can be evenly distributed on the side wall of the centrifugal cylinder 4 in a tangential direction, further enhancing the centrifugal effect. The dust falling channel 6 is formed between the side wall of the centrifugal cylinder 4 and the shell 1, the upper end of the body 1 is fixed with an exhaust pipe 7, and the exhaust pipe 7 extends into the centrifuga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com