Method and application equipment for desulphurization in furnace of boiler with desulphurization ash in semi-dry process

A semi-dry desulfurization and boiler furnace technology, applied in the field of desulfurization, can solve the problems of wasting absorbents, etc., and achieve the effects of reducing desulfurization costs, solving difficulties in being used, and solving waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 of the present invention: a method for using semi-dry desulfurization ash in a boiler furnace for desulfurization in a boiler. Dry desulfurization ash is produced during semi-dry flue gas desulfurization, and an additional installation is installed on the pipeline for the warehouse pump to transport the dry desulfurization ash to the ash store One pipeline, the dry desulfurization ash is sent to the furnace of the boiler through the additional pipeline for desulfurization reaction in the furnace.

[0024] The composition of the dry desulfurization ash includes desulfurization reaction products, unconsumed absorbent and flue fly ash. The dry desulfurization ash is transformed into fly ash after participating in the desulfurization reaction in the furnace.

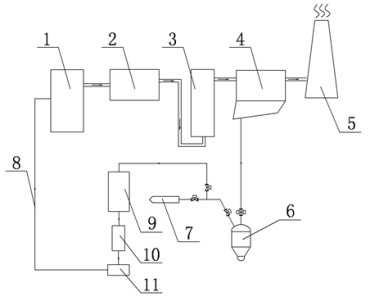

[0025] A device used to realize the aforementioned semi-dry desulfurization ash used in the desulfurization method in the boiler furnace, including a boiler 1, a dust collector 2, a semi-dry desulfurizati...

Embodiment 2

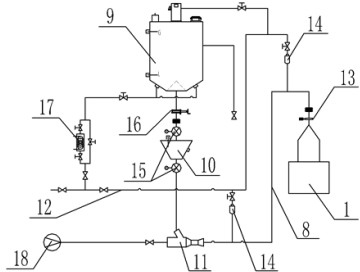

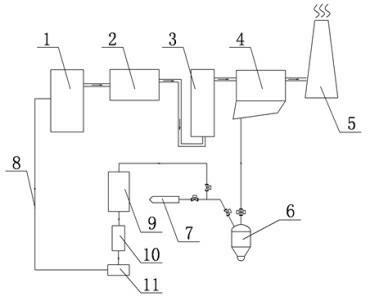

[0026] Embodiment 2 of the present invention: as figure 1 with figure 2 As shown in the figure, a semi-dry desulfurization ash is used for desulfurization in the boiler furnace. During the semi-dry flue gas desulfurization, dry desulfurization ash is produced, and a pipeline is added to the pipeline for the warehouse pump to transport the dry desulfurization ash to the ash store. After the desulfurized ash enters the added pipeline, it is first transported to the intermediate ash bin through the pipeline, then transported from the intermediate ash bin to the metering bin through the pipeline, and finally sent from the metering bin to the jet pump, which is sprayed into the boiler by the jet pump. To the coal mouth.

[0027] The composition of the dry desulfurization ash includes desulfurization reaction products, unconsumed absorbent and flue fly ash. The dry desulfurization ash is transformed into fly ash after participating in the desulfurization reaction in the furnace. ...

Embodiment 3

[0032] Embodiment 3 of the present invention: as figure 1 with figure 2 As shown in the figure, a semi-dry desulfurization ash is used for desulfurization in the boiler furnace. During the semi-dry flue gas desulfurization, dry desulfurization ash is produced, and a pipeline is added to the pipeline for the warehouse pump to transport the dry desulfurization ash to the ash store. After the desulfurized ash enters the added pipeline, it is first transported to the intermediate ash bin through the pipeline, then transported from the intermediate ash bin to the metering bin through the pipeline, and finally sent from the metering bin to the jet pump, which is sprayed into the furnace of the boiler .

[0033] The composition of the dry desulfurization ash includes desulfurization reaction products, unconsumed absorbent and flue fly ash. The dry desulfurization ash is transformed into fly ash after participating in the desulfurization reaction in the furnace.

[0034] A device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com