Guide wheel device on numerical control multi-wire swinging cutting machine

A cutting machine and guide wheel technology, applied to fine working devices, working accessories, stone processing equipment, etc., can solve the problems of increasing broken wires, achieve the effects of improving actual life, reducing the probability of wire breaking, and extending life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

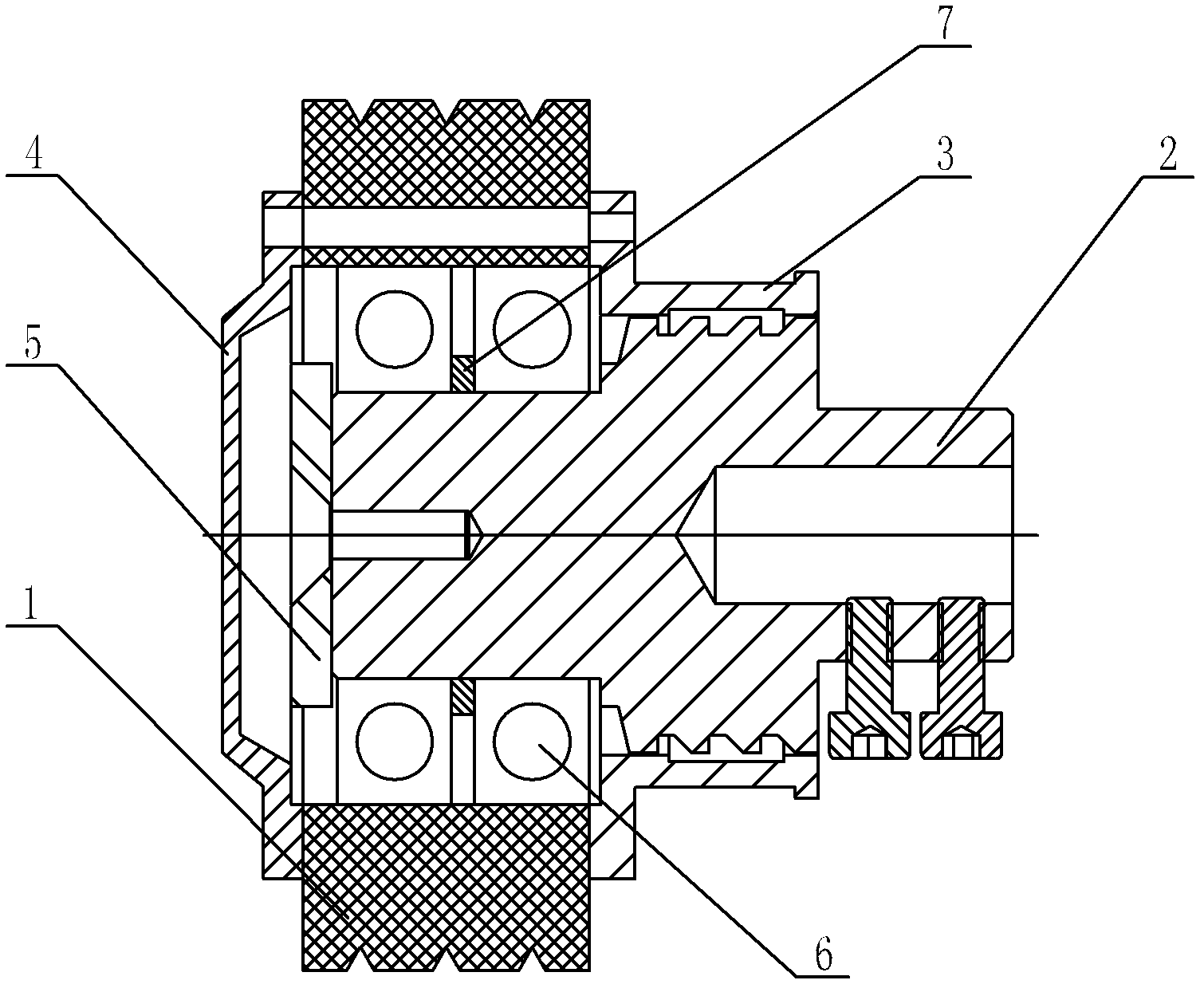

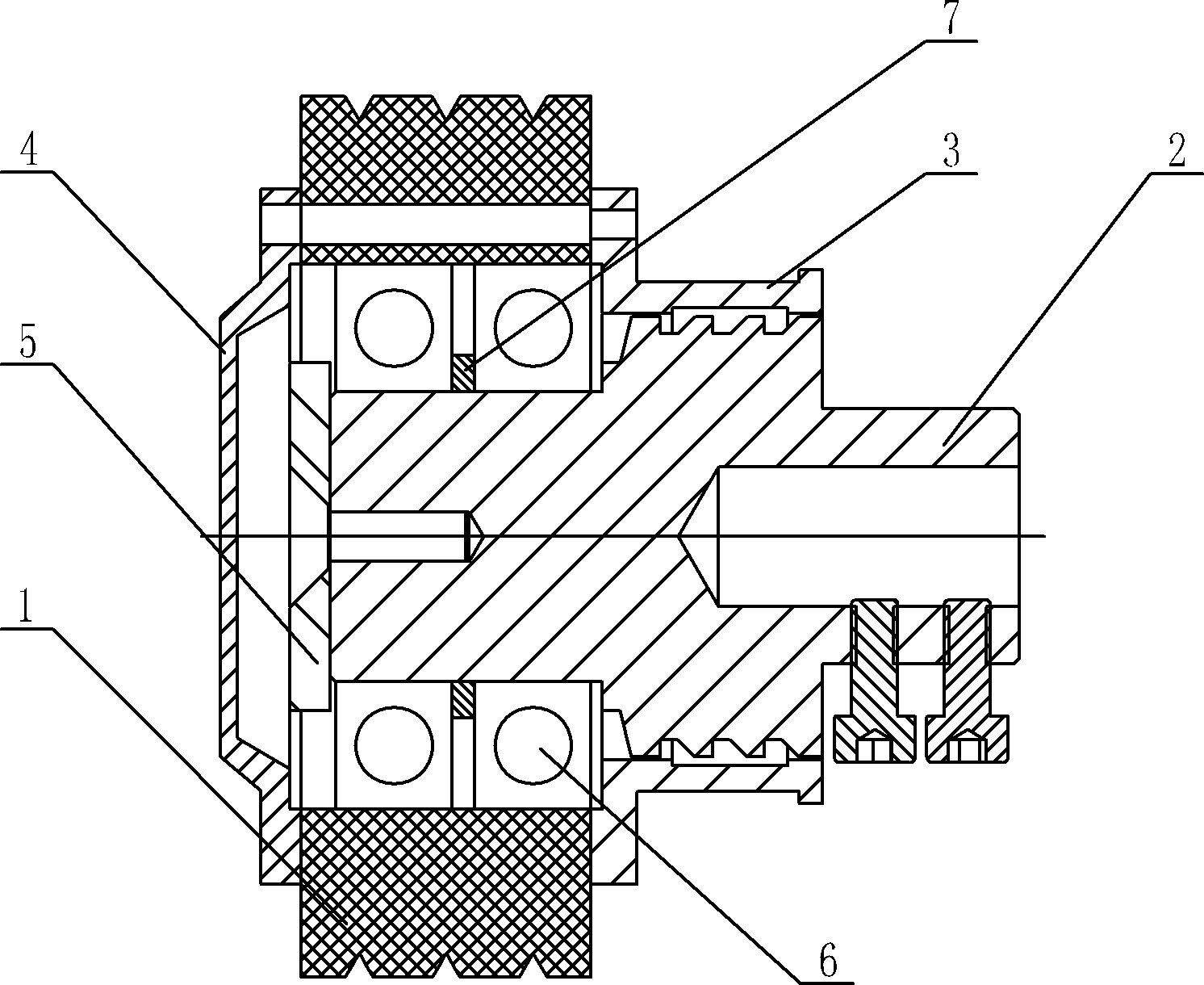

[0009] The present invention will be further described below in conjunction with specific drawings.

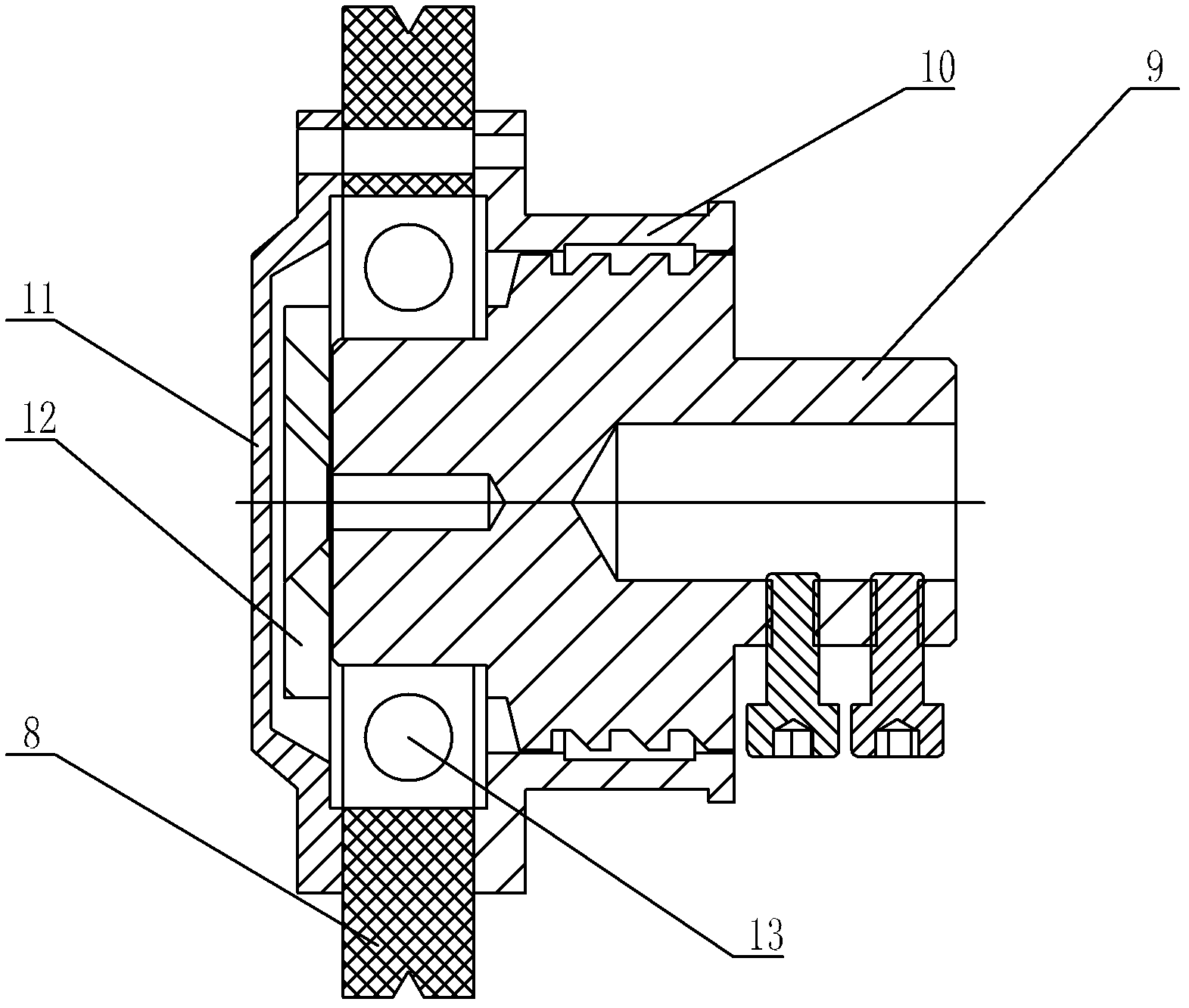

[0010] Such as figure 2 Shown: The guide wheel device used on the CNC multi-wire swing cutting machine includes a large guide wheel 1, a large wheel shaft 2, a rear gland 3, a front gland 4, a pressure pad 5, a bearing 6, and a spacer 7.

[0011] The present invention includes a large wheel shaft 2, on which a large guide wheel 1 is installed, and the large guide wheel 1 is installed on the large wheel shaft 2 through two pairs of bearings 6, and a spacer is arranged between the two pairs of bearings 6 7; Install the front gland 4 at the front end of the large guide wheel 1, set the pressure pad 5 between the front gland 4 and the large wheel shaft 2, and install the rear gland 3 at the rear end of the large guide wheel 1; The width of the large guide wheel 1 is wider than that of the prior art, and three grooves are provided on the outer peripheral surface of the large guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com