Separated section type diamond wire and production method thereof

A technology of diamond wire and production method, applied in glass production, stone processing equipment, stone processing tools, etc., can solve the problems of low production efficiency, difficult to discharge fine chips, easy broken diamond wire, etc., so as to improve cutting efficiency and reduce breakage. Line probability, the effect of reducing cutting resistance

Inactive Publication Date: 2012-06-20

CHANGSHA DIAT NEW MATERIAL SCI & TECH

View PDF6 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The purpose of the present invention is to provide a segmented diamond wire and its production method to solve the technical problems that fine chips are difficult to discharge during production, the diamond wire is easy to break, and the production efficiency is low.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Login to View More

Abstract

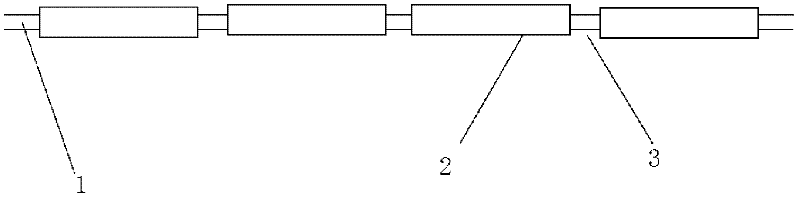

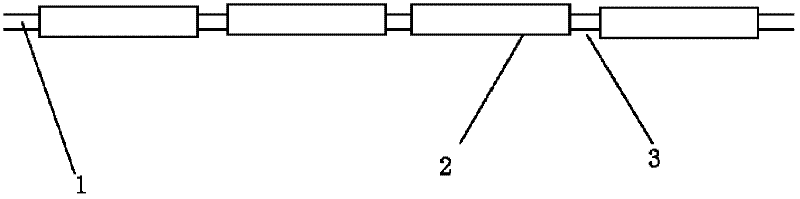

The invention provides a separated section type diamond wire and a production method thereof. The separated section type diamond wire comprises a base line and coatings coated on the surface of the base line, wherein the coatings are arranged at intervals; a spacer area is formed between every two coatings; the coatings have the length of 50 to 100cm; and the length of the spacer area ranges from 1 to 10cm. Fine scraps can be accommodated in spaces between every two coatings on the surface of the separated section type diamond wire during production, particularly in the process of cutting large-size materials; and moreover, the fine scraps can be taken out of cutting seams in the process of cutting running wires, the scraps accommodating rate and scraps discharging capacity of the diamond wire are obviously improved, cooling and lubricating effects of a cooling liquid are improved, the cutting resistance is reduced, the line breaking probability is reduced, and the cutting efficiency of the diamond wire is improved.

Description

technical field [0001] The invention relates to the field of diamond wire production, in particular, to a segmented diamond wire. Furthermore, the present invention also relates to a production method comprising a segmented diamond wire as described above. Background technique [0002] Diamond wire is a cutting tool made by consolidating high hardness and high wear resistance diamond abrasive grains on the surface of steel wire matrix. Diamond wire can not only process ordinary hard and brittle materials such as stone and glass, but also can be as small as 0.15mm because of its narrow kerf. Therefore, it is especially suitable for cutting precious hard and brittle materials such as gemstones, agate, ceramics, and crystals. Diamond wire can be made into different diameters and lengths according to the needs of the material to be cut; diamond wire can also be installed on different equipment to form different processing methods, such as reciprocating cycle (saw frame) type, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B28D1/06B28D5/04B28D7/02C25D15/00C25D5/18C03B33/00C03B33/12

CPCY02P40/57

Inventor 刘纯辉

Owner CHANGSHA DIAT NEW MATERIAL SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com