Damping mechanism for winding system of wire cutting machine

A technology of wire cutting machine and vibration damping mechanism, which is applied in the direction of non-rotational vibration suppression, electric processing equipment, metal processing equipment, etc., can solve the problems of poor processing accuracy, unstable tension, insufficient damping, etc., to improve processing quality, The effect of reducing the probability of disconnection and increasing the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0101] In order to present the content of the present invention more specifically, the implementation forms of the present invention will be described in detail below with reference to the drawings.

[0102] First implementation type:

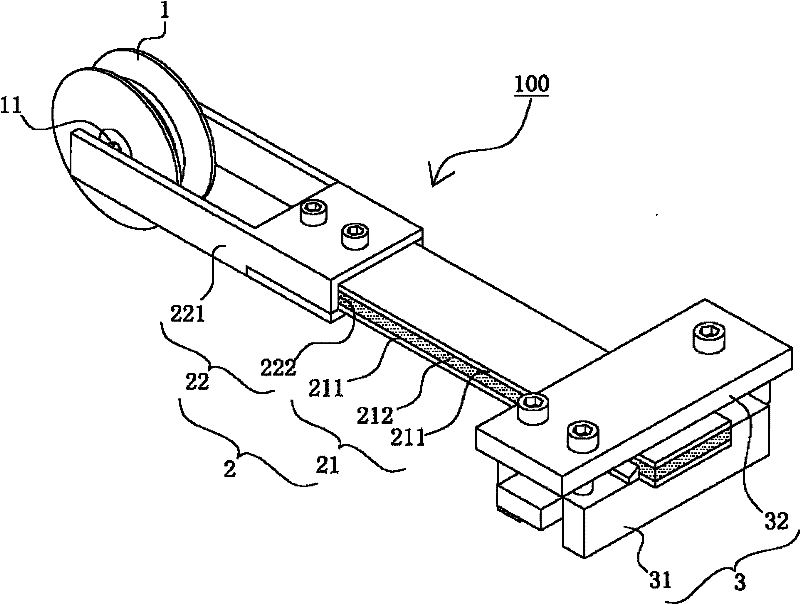

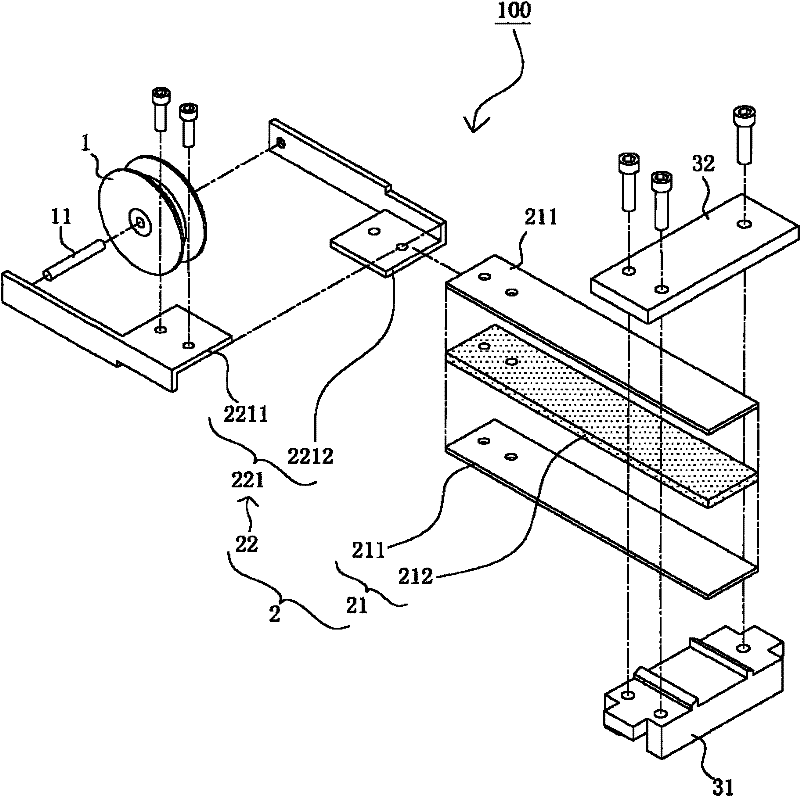

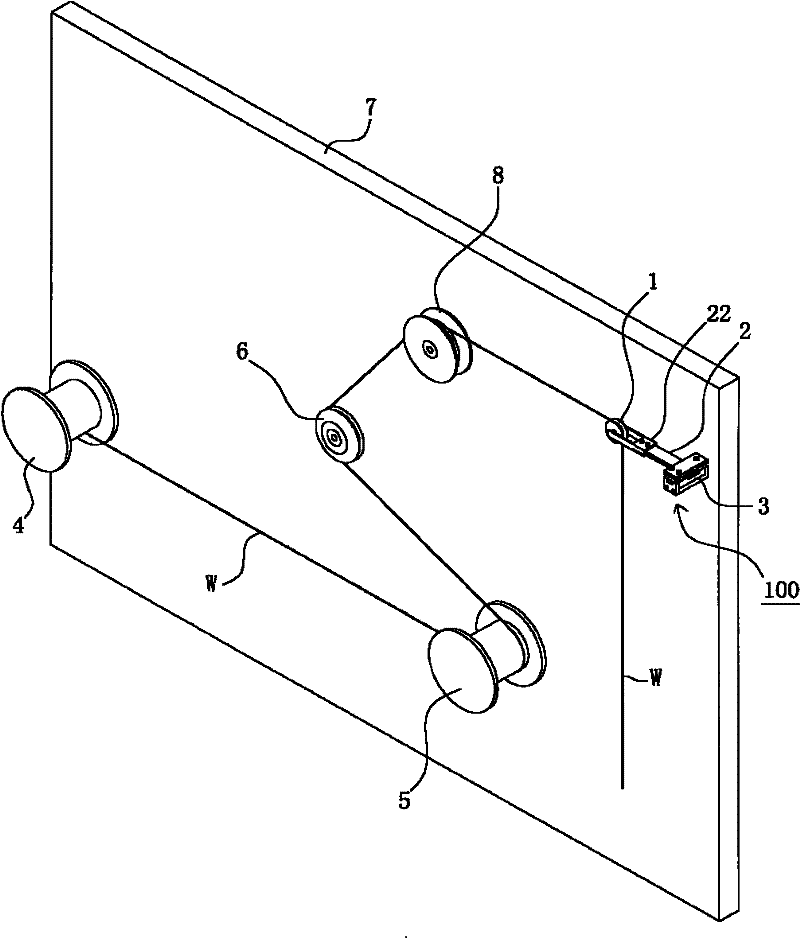

[0103] like figure 1 Shown is a three-dimensional schematic view of the first embodiment of the present invention, such as figure 2 Shown is a three-dimensional exploded view of the first embodiment of the present invention.

[0104] It is disclosed in the drawing that it is a vibration damping mechanism (100) of a wire cutting machine winding system, which includes:

[0105] One axle is provided with the roller (1) of wheel axle (11);

[0106] at least one shock-absorbing rod (2) connected to the roller (1); and

[0107] A fixed base (3) capable of fixing the vibration-absorbing rod (2);

[0108] It is characterized by:

[0109] The vibration-absorbing rod (2) is arranged between the roller (1) and the fixed base (3), one end thereof is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com