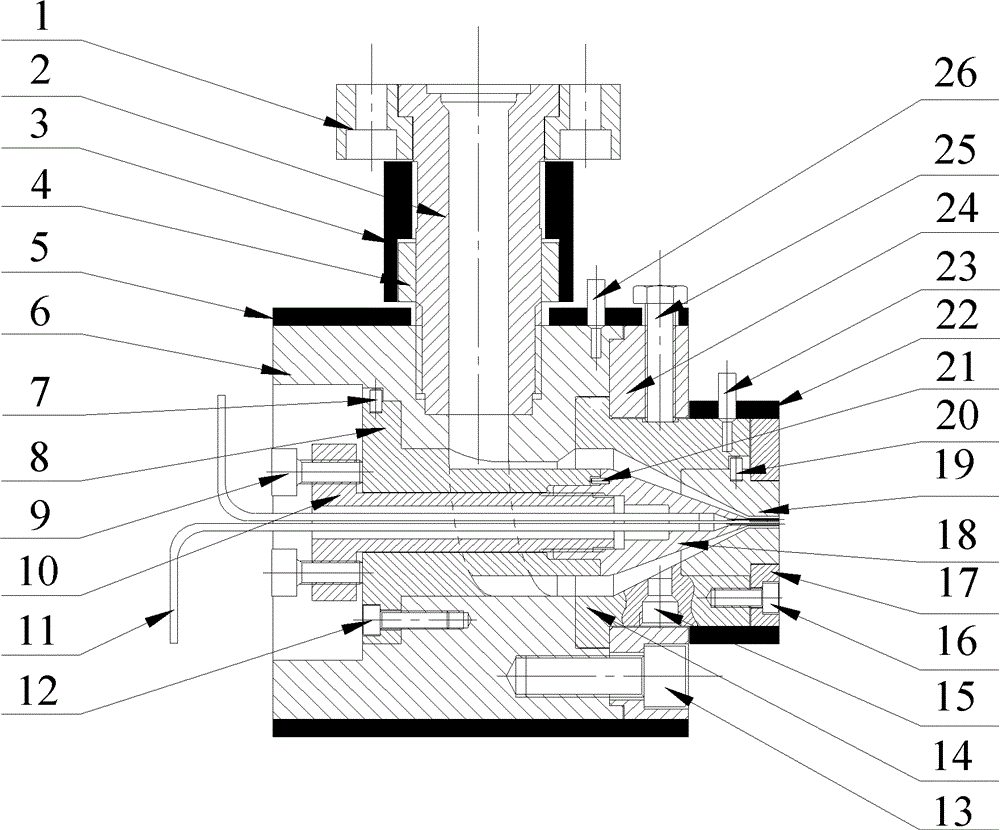

Right-angle extrusion die for multi-cavity plastic micro-pipe

A multi-cavity plastic micro-tube, right-angle extrusion technology, applied in the field of plastic extrusion molding, can solve the problems of high design and processing costs, multi-cavity tube cross-sectional shape accuracy can not meet the requirements, poor reliability, etc., to reduce mold design and The effect of reducing manufacturing cost, shortening the development cycle, and improving molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0013] A kind of TPU multi-cavity microtube is extruded using the die of the present invention, and the steps of the embodiment are as follows:

[0014] step 1

[0015] Use a drying oven to dry the TPU at a certain temperature for a specific time to remove moisture.

[0016] step 2

[0017] Mount the die to the extruder with heater coils, thermocouples and integrated pressure / temperature sensors.

[0018] step 3

[0019] Start the extruder, set the screw speed of the extruder and the temperature of each section of the barrel, and use the heating ring and thermocouple to heat each area of the mold to the set temperature in stages and keep it warm for a certain period of time.

[0020] step 4

[0021] Adjust the gap between the die and the mandrel by adjusting the adjusting bolt on the die, so that the mandrel and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com