Die head of extrusion die capable of embossing on adjacent surfaces of section bar

A technology of adjacent surfaces and extrusion dies, applied in the field of extrusion dies, can solve the problems of widening the distance between the die head and the shaping die, unstable production of profiles, and easy deformation, so as to increase the difficulty of operation and ensure normal stability production, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

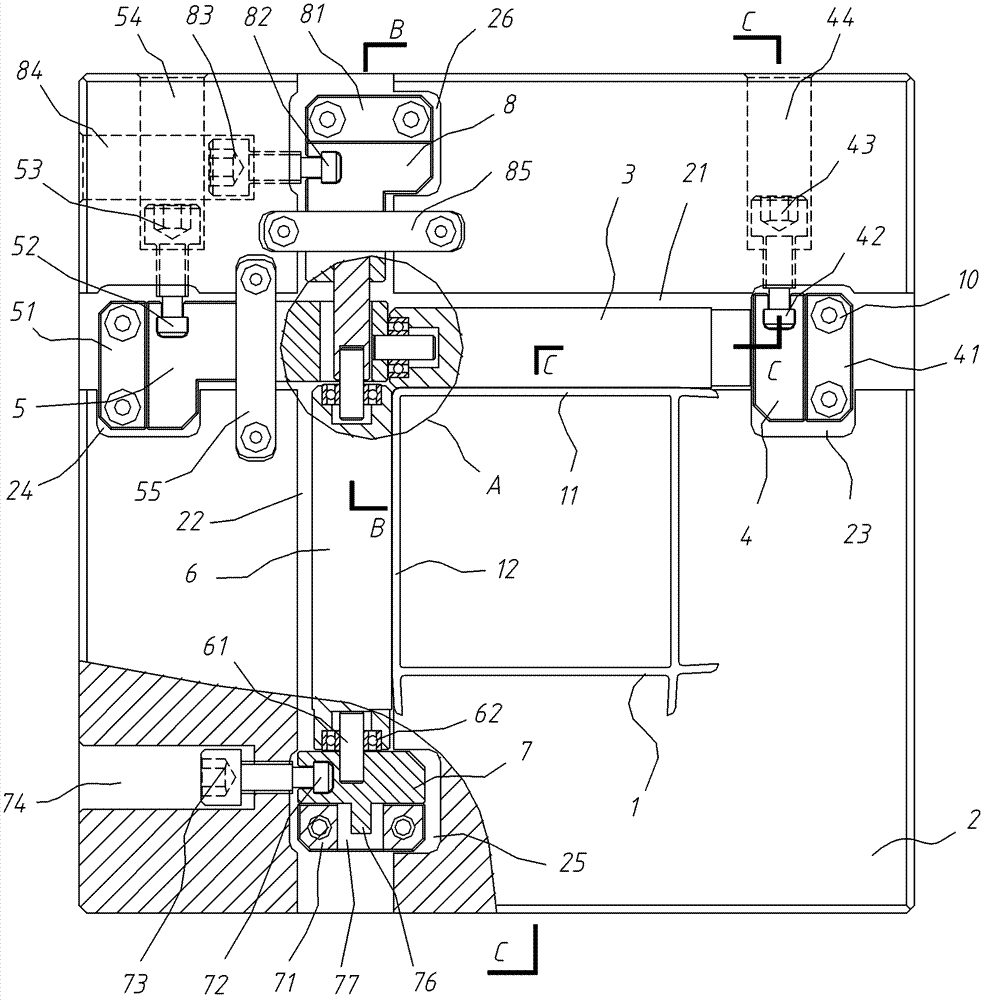

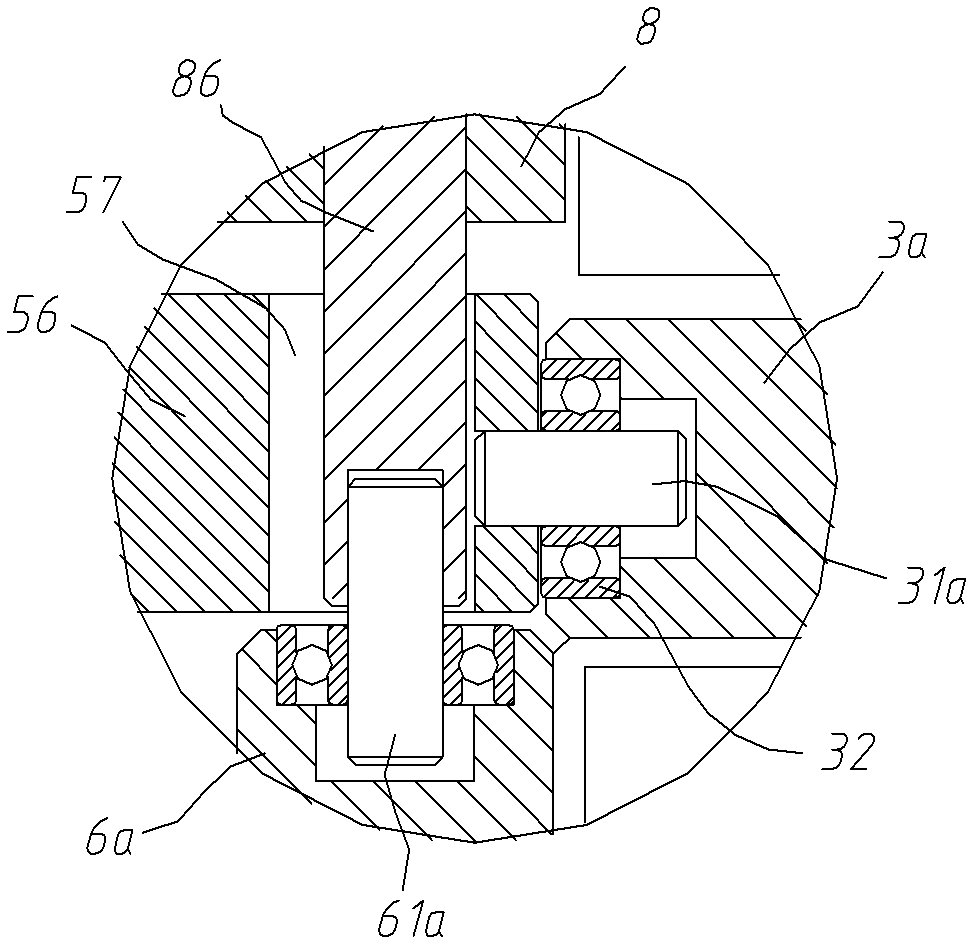

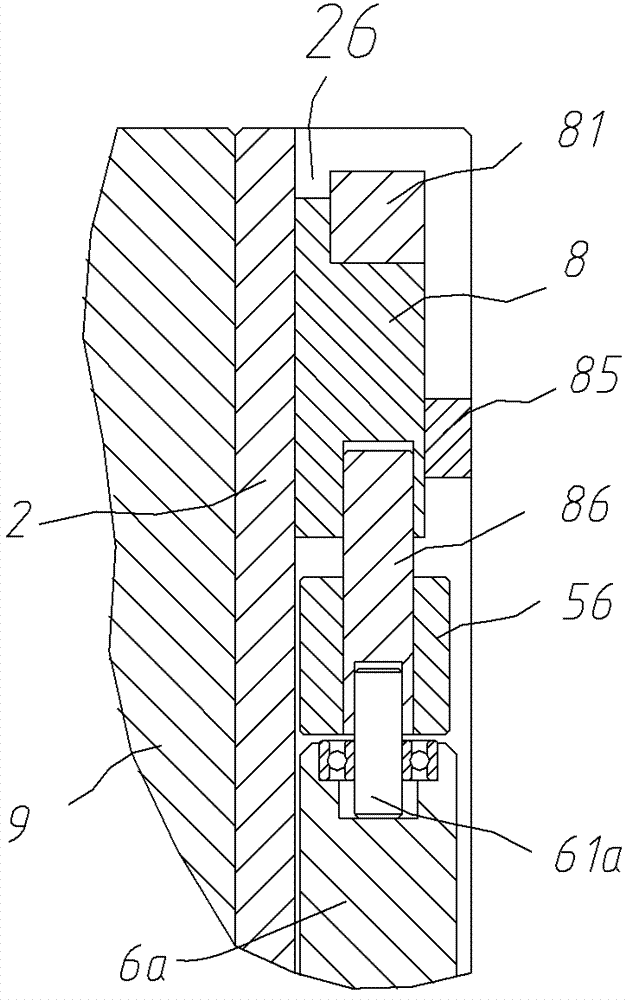

[0012] Such as figure 1 As shown, the forming plate 2 is provided with horizontally arranged first embossing roller mounting grooves 21 and its fixing bracket mounting grooves 23, 24 on the outer sides of the two adjacent surfaces 11, 12 to be embossed at the outlet end of the profile 1, and The vertically distributed second embossing roller installation groove 22 and its fixed bracket installation groove 25, 26, the two installation grooves 21, 22 are arranged on the same building surface of the forming plate 2, so that after the two embossing rollers 3, 6 are installed Their axes are on the same plane of establishment.

[0013] The two ends of the first and second embossing rollers 3 and 6 are respectively fixed with pivot shafts 31 and 61 through built-in bearings 32 and 62 . The fixed bracket 5 of the first embossing roll at the adjacent end 3a has a protruding portion 56 passing through the end of the second embossing roll adjacent end 6a and extending to the end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com