Magnetic force controlled ink permeating type micro-contact printing device

A technology of micro-contact printing and magnetic force control, applied in printing, stamping, etc., can solve the problems of difficult printing of large-area patterns, time-consuming and labor-consuming stamps, and limited size of elastic stamps, and achieve continuous ink filling and saving usage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

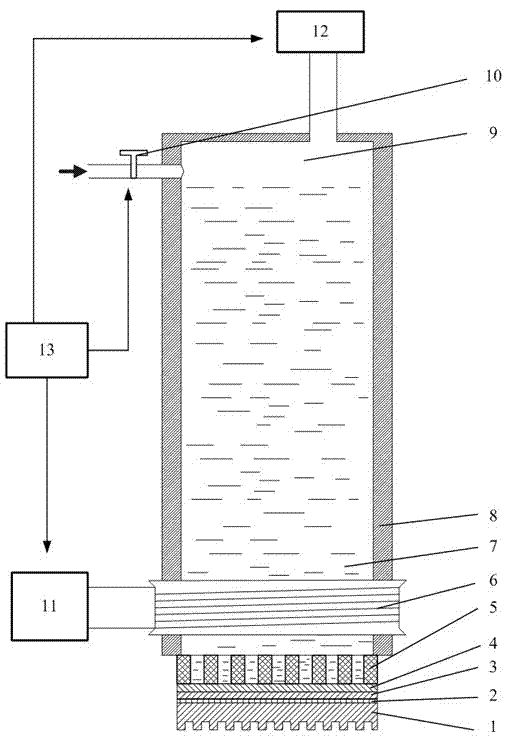

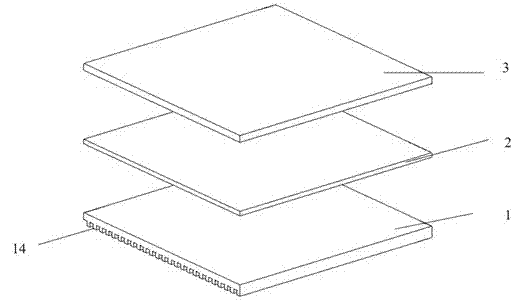

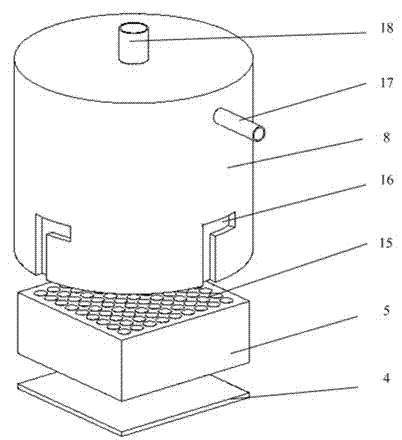

[0025] Such as figure 1 , image 3 , Figure 4 As shown, the present invention includes a pattern layer 1, a magnetically sensitive layer 2, a sealing layer 3, a permeable layer 4, a support layer 5, a coil sleeve 19, an ink tank 8, and an electromagnetic flow valve 10; the lower end surface of the pattern layer 1 has a pattern, and the pattern The upper end surface of the layer 1 is provided with a magnetic sensitive layer 2, a sealing layer 3, a permeable layer 4, a support layer 5 and a cylindrical ink tank 8 in sequence; a coil sleeve 19 is provided on the cylindrical surface of the ink tank 8 near the end of the support layer 5 The ink feed pipe 17 on the ink tank 8 cylindrical surface away from the support layer 5 is provided with an electromagnetic flow valve 10; the top surface of the ink tank 8 is provided with a pneumatic communication pipe 18; the coil and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com