Heavy draught truss type floating platform

A technology of floating platforms and water trusses, which is applied to floating buildings and other directions, can solve the problems of difficult design and installation of tension legs, difficult layout of oil and gas treatment facilities, rising cost of tension leg platforms, etc., and achieve good heave motion performance, The effect of meeting the requirements of dry oil recovery and reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

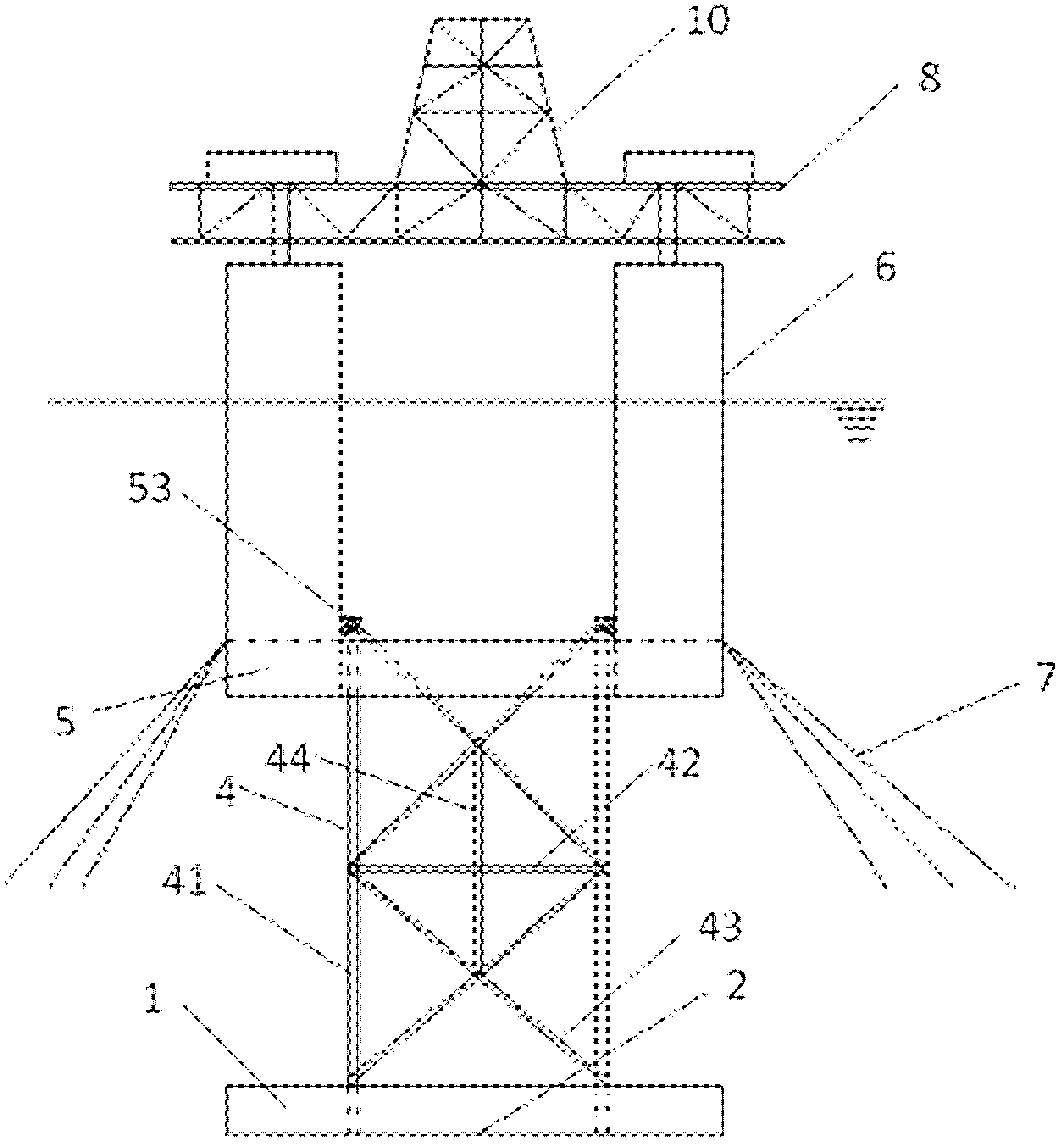

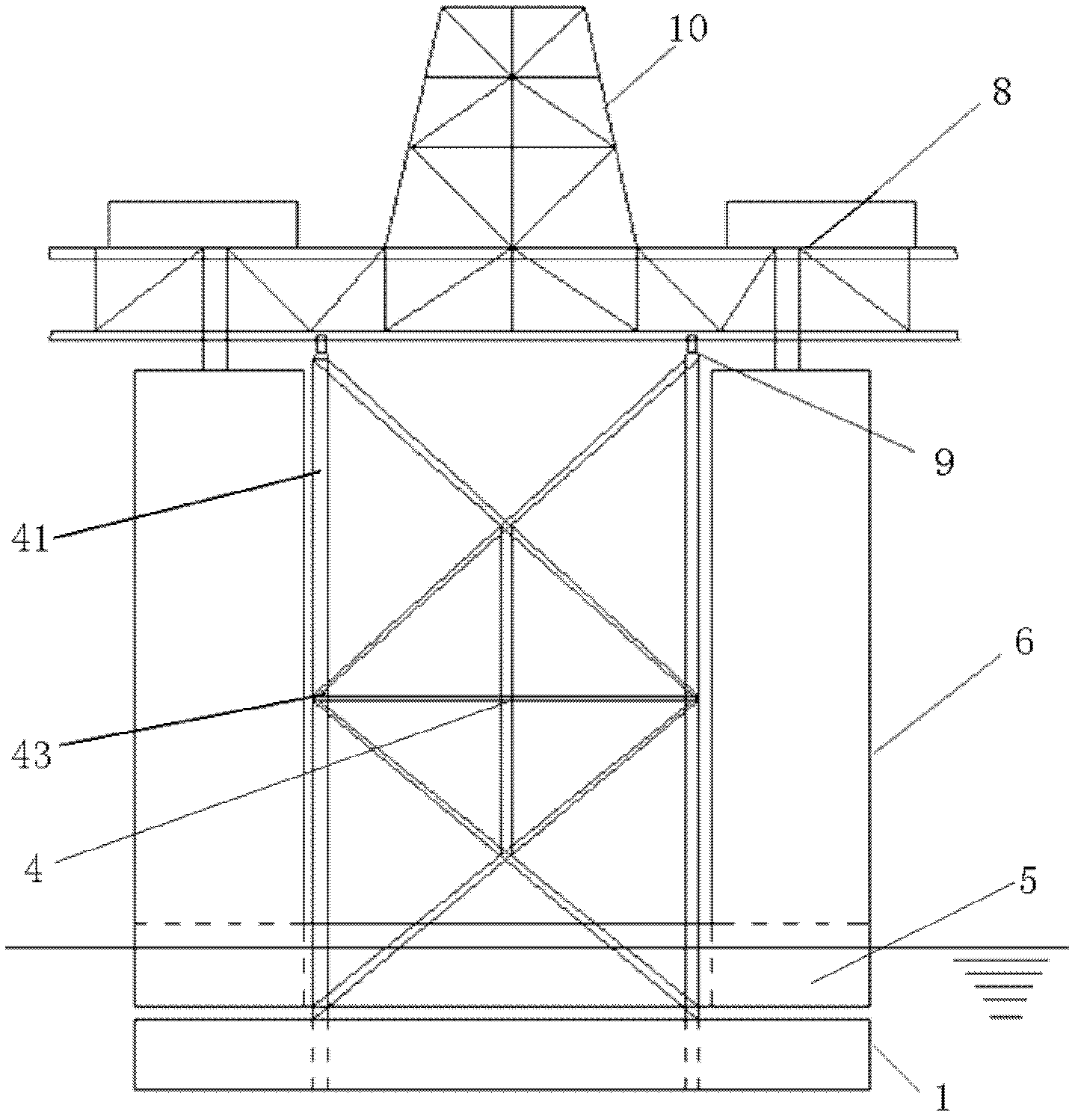

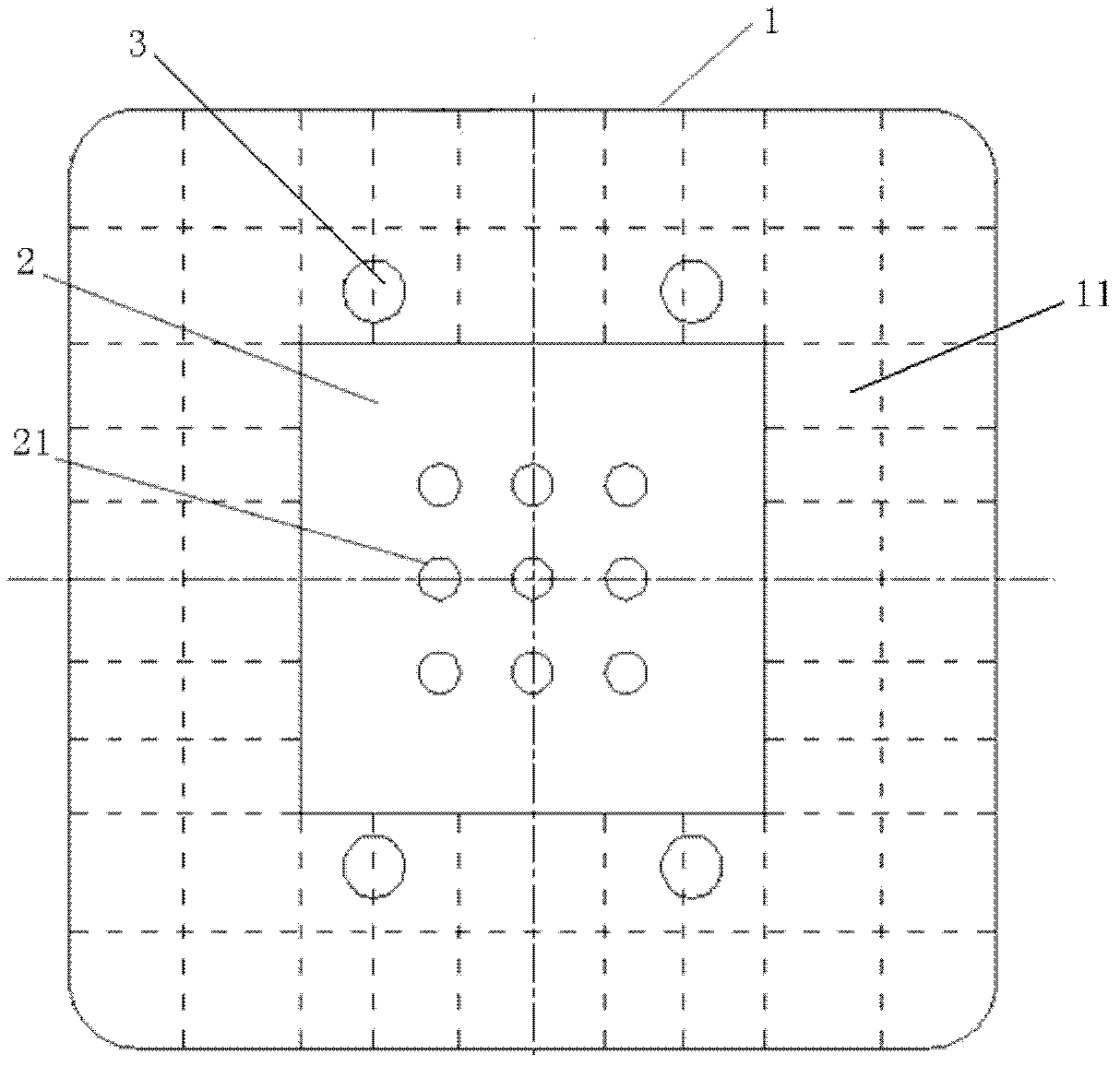

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention comprises a lower buoyancy tank 1 with a square hole in the center, several watertight cabins 11 are arranged at intervals in the lower buoyancy tank 1, and weights for ballasting are arranged in the watertight cabins 11; The heave plate 2 connected as a whole, the heave plate 2 is provided with a plurality of through holes 21, and the top of the lower buoyancy tank 1 is provided with a plurality of connecting holes 3, through which a space truss 4 is fixedly connected with it and welded as a whole, The top of the space truss 4 passes through a square hole arranged in the center of a floating tank 5, and a circle of watertight passages 51 are arranged in the floating tank 5; several watertight cabins 52 are arranged on both sides of the watertight passage 51;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com