Concrete foundation embedded bolt bracket and embedding method for concrete foundation embedded bolts

A technology of concrete foundation and pre-embedded bolts, applied in the direction of basic structure engineering, construction, etc., can solve problems such as elevation error, high construction precision requirements, and different settlements, so as to eliminate displacement and settlement, improve work efficiency, and improve forecasting. The effect of buried precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

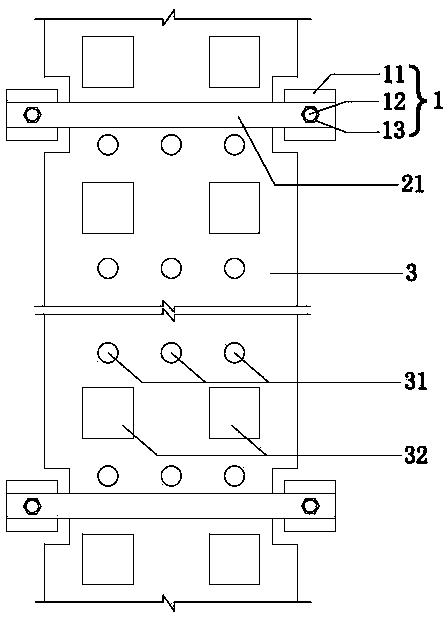

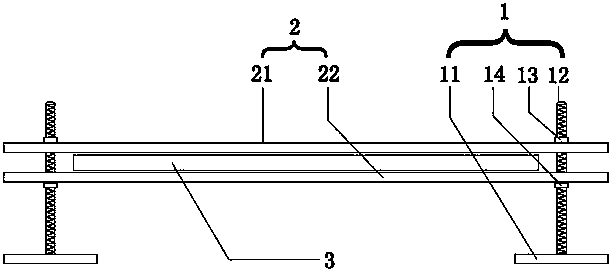

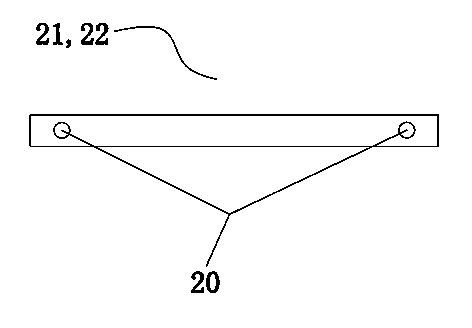

[0025] like Figure 1 to Figure 5 As shown, in this embodiment, the pre-embedded bolt bracket of the concrete foundation includes four sets of support components 1, two sets of clip steel plates 2 and steel formwork 3, and each set of support components 1 corresponds to one set of clip steel plates 2, of course, In this embodiment, it is not limited to four sets of support components 1 and two sets of clamping steel plates 2 , which can be appropriately increased according to the length of the steel template 3 .

[0026] Please continue to refer Figure 1 to Figure 5 , the support assembly 1 is arranged on the side of the steel formwork 3, and each set of support assemblies 1 includes a steel plate base 11, a screw rod 12 erected on the steel plate base 11, and an upper nut 13 and a lower nut screwed on the screw rod 12. Nut 14; wherein, the steel plate base 11 is a 20mm thick 200×100mm wide steel plate, and its width and thickness can be adjusted according to the actual situ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com