Shock-proof mechanical magnetic lock

A magnetic lock and mechanical technology, applied in the field of locks, can solve the problems of easy locking of balls and pull bolts, easy breakage of return springs, poor impact resistance, etc., to reduce the probability of locking, improve safety, and simple opening structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

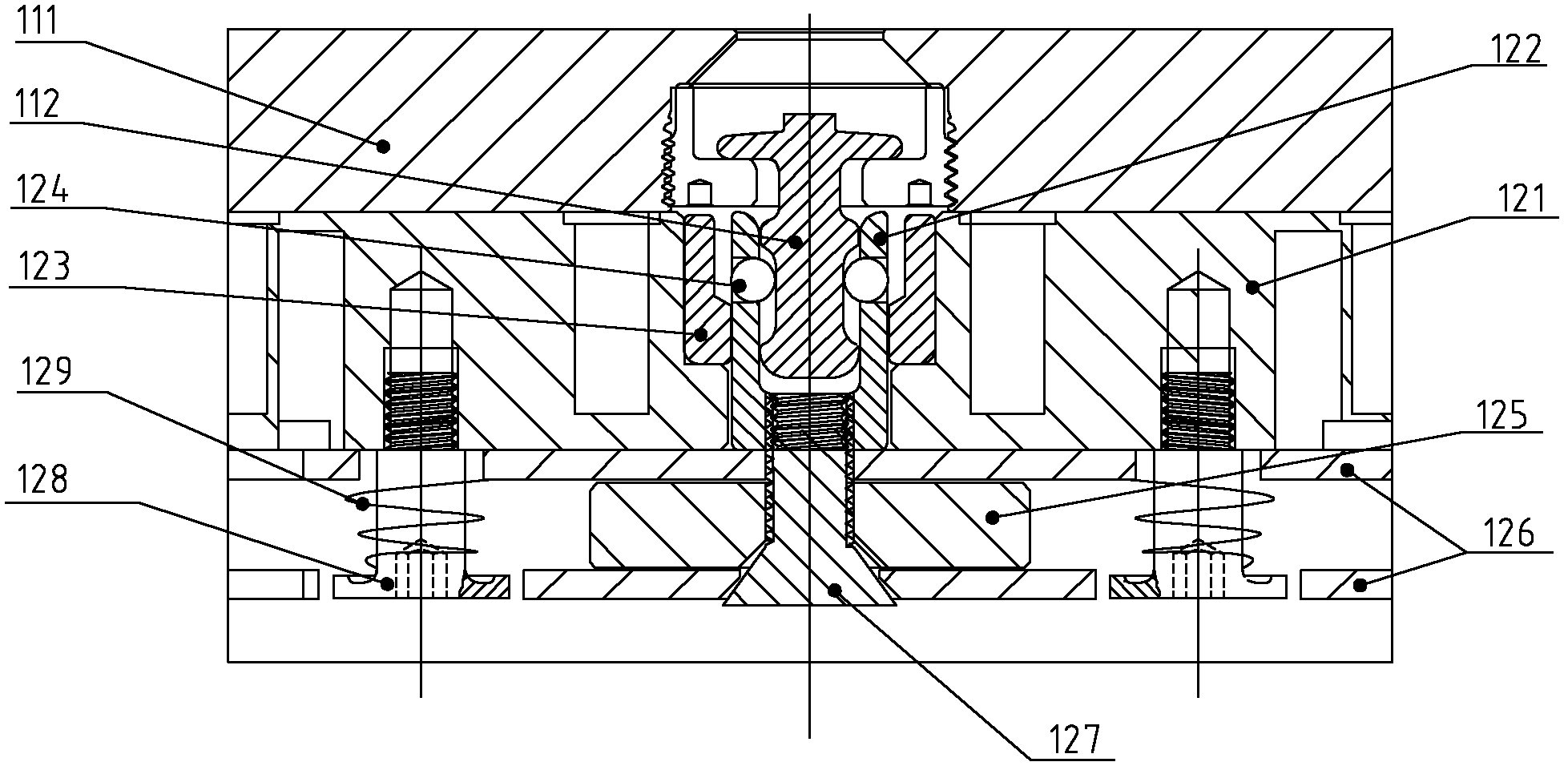

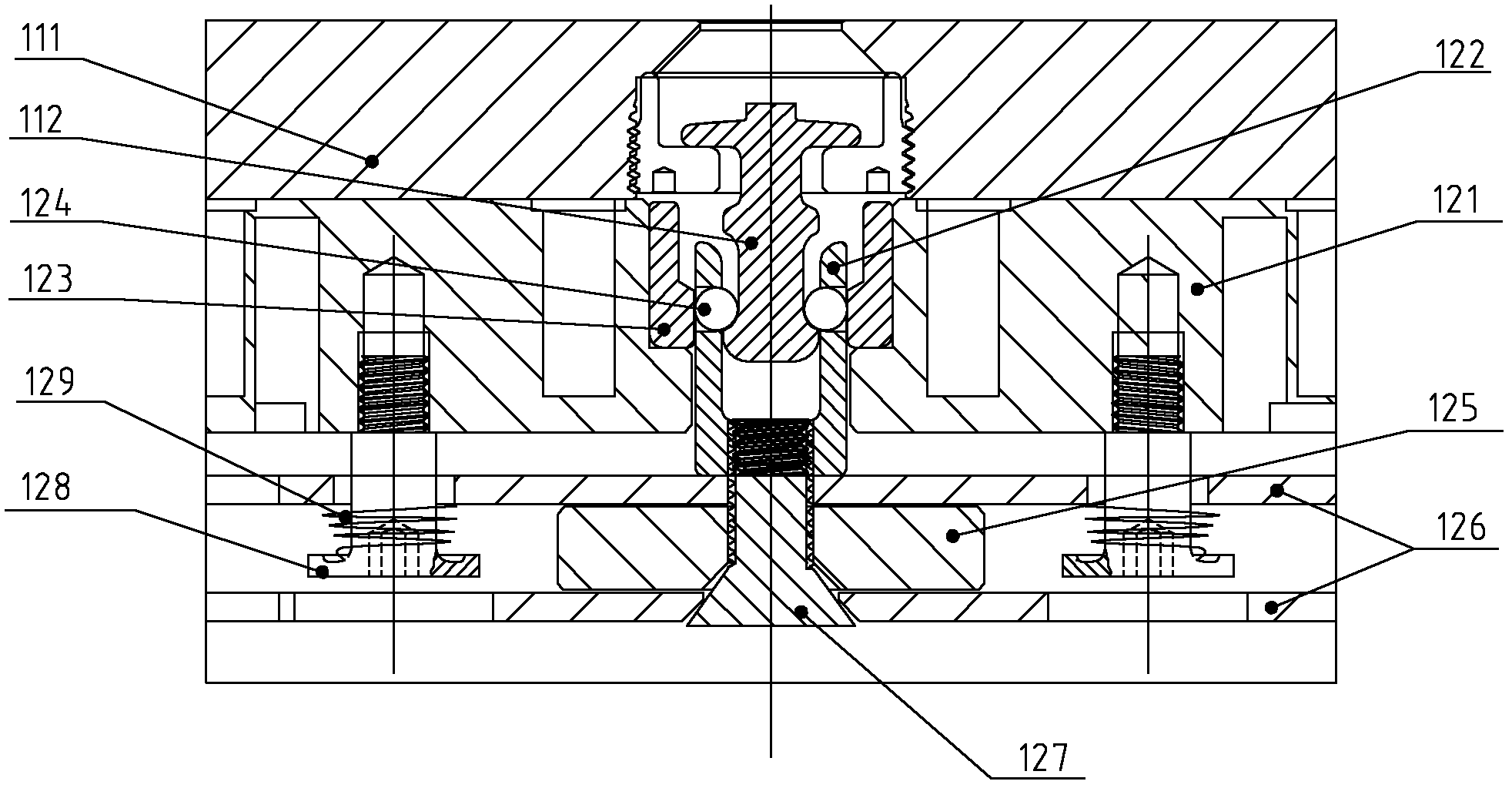

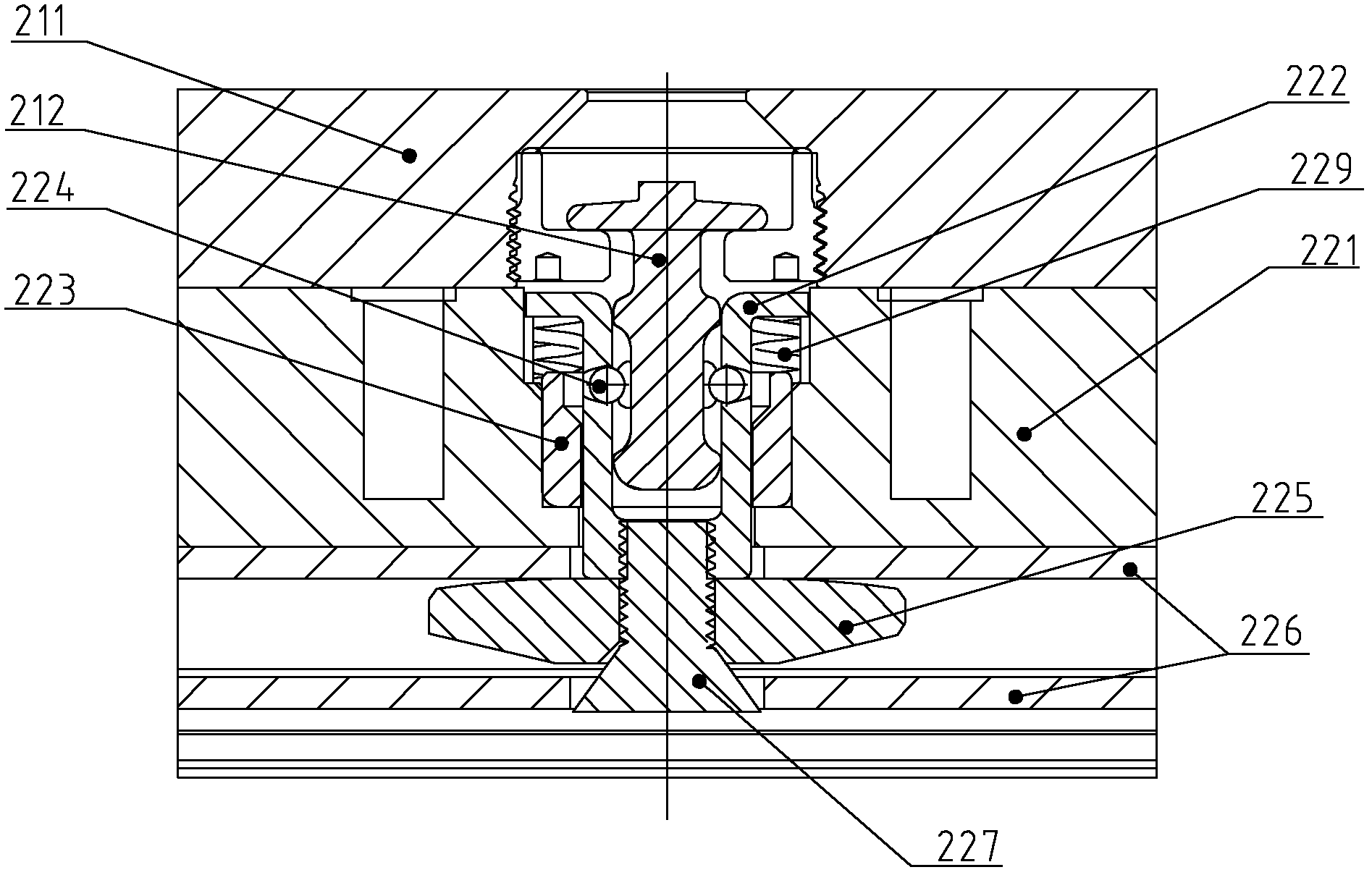

[0027] Such as image 3 with Figure 4 As shown, the shock-absorbing mechanical magnetic lock of the present invention includes an iron plate 211 on one side, a pull bolt 212 protruding vertically from the iron plate 211, and a magnet 221 on the other side, which is located in the magnet 221 and the top opening can Insert the sleeve 222 of the pull bolt 212 and the stop ring 223 sleeved on the periphery of the sleeve 222 . Wherein, the end of the pull bolt 212 forms a flange. The sleeve 222 and the stop ring 223 have a mechanism that cooperates with each other to adjust the aperture of the sleeve 222 internal cavity. On the other hand, a step is formed on the inner surface of the side wall of the snap ring 223, and the diameter of the upper portion of the inner cavity of the snap ring 223 is larger than that of the lower portion. The stop ring 223 is fixed on the magnet 221, and the bottom of the sleeve 222 can be rotatably installed on the base plate 226 below the magnet 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com